| Author | Message | ||

Werewulf |

i had tire wear problems on my v-rod that the dealer couldnt correct...so i loosened everything that could put stress on the motor (pipes etc) and took the tension off the engine brace turn-buckles...the result, was less vibration and an end to the tire wear glitch...i noticed when i was installing my nallin front mount on my S-3, that both turn-buckles had stress on them.. i looked in the service manual and it said not to adjust them, as they are set at the factory...i would think that stress in this area would put stress on the front motor mount and lead to failure... so i adjusted them anyway... anyone else delt with this situation? (Message edited by werewulf on April 25, 2008) | ||

Djkaplan |

I think what they really mean is that the tie-bar lengths are 'aligned' with each other and shouldn't be adjusted independently of each other. When I added the 4th tie-bar to my M2's front mount (the mounting holes were already there in the frame and mount), I adjusted the length so it would fit in the holes with no tension. That seemed to work fine, no odd vibrations or sensations. | ||

Buellistic |

These are referred to as "TIE BARS" and should be set up with new Front(1) and rear(2) isolators(TUBE FRAME BUELL) ... "i" too added a front head motor mount to frame "TIE BAR" ... "i" set it up with with the used (many miles on it front isolator), THE adjustment is rechecked if "i" change any isolators ... | ||

Werewulf |

where be this new "tie bar" that you are talking about?? | ||

Jos51700 |

You have just screwed your bike. The Vrod uses the swingarm pivot in conjunction with the rear motor mounts to positively locate the engine and swingarm to the frame. All the tierods do is allow the motor move independent of the chassis to avoid transmission of vibes to your tush. Your Buell uses the tie-bars all by themselves to align the rear wheel (Through the engine/transmission, which "floats" in the frame) with the front wheel. The two wheels are not solidly connected in any way (Unlike the 'Rod), and you have now upset that alignment. So, exactly HOW did you determine what "proper" was? Of course they were stressed. That's their job. | ||

Jos51700 |

"where be this new "tie bar" that you are talking about??" It lives up underneath the front motormount, parallel to the other front tie bar. | ||

Jos51700 |

"These are referred to as "TIE BARS" and should be set up with new Front(1) and rear(2) isolators" I'm assuming that by "set up" you mean "adjusted", but I could be misunderstanding, and apologize if so. The only reason one should EVER touch the tie-bars on a tubie, is because of a verified, measured, wheel misalignment. The procedure for alignment measurement is outlined in the HD FLT service manual (The chassis theory and layout of the FLT, supposedly designed by Erik Buell, is practically identical to the tube-frame Buell). Ever wonder why XB's get non-adjustable tie-bars? 'Cus they're not meant to messed with! | ||

Werewulf |

maybe i dont know what you mean about the v-rod tie-bars, ..but for clarification, the tie-bar on the v-rod is used to align the motor, which in turn aligns the rear wheel and determines he entire chasis alignment...there is an entire section in the manual about it. but this isnt the v-rod forum, is it? (Message edited by werewulf on April 25, 2008) | ||

Werewulf |

i was also reading the instructions for the stenzel brace and its important that no preload be on the brace... i cant imagine preload on an engine that vibrates like a buell, being a good thing... preload on the exhaust system was one thing that led to mount failure....so, if you have never adjusted yours, you dont know either! | ||

Buellistic |

Jos517: Set up equals adjusted ... Wonder how many BUELLers ever thought about just checking their wheel alignment??? Believe that was the FXRT ... In the FUELL Magizne(spring 2008) the FXR platform was mentioned on page 4 ... | ||

Jos51700 |

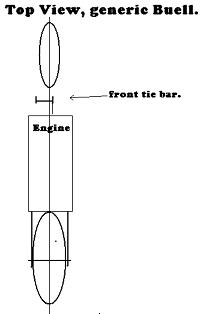

Let's look at the front tie bar on your typical tube frame Buell. We'll assume the tie bar length is 1 unit, and as we know, the rear swingarm pivots on the swingarm block attached to the motor, and is not attached to the frame.  | ||

Jos51700 |

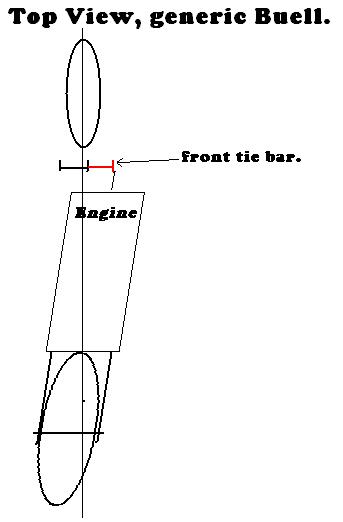

Here's our theoretical Buell, after adding an additional adjustment of approximately one more unit in length in the front tie-bar. This is an exaggeration for illustrative purposes, but when you factor a small change over a distance, it makes big changes. (And to be fair, the pivot point on the Buell is the rear motor mounts, and in the illustration, it's pivoted at the bottom of the "rear tire"  . . Notice how much the angle of the rear wheel is out-of-line with the front?  | ||

Jos51700 |

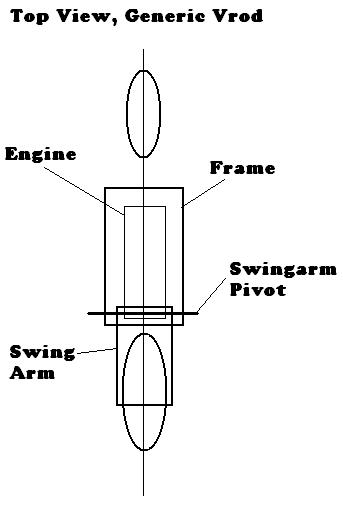

And, to clarify, here's our theoretical Vrod. The engine and swingarm are joined by the swingarm pivot shaft, because keeping the swingarm and engine aligned is critical. However, the Swingarm pivot shaft is also mounted to the frame. The tie-bars accept some of the load (Similar to illustration #1, for example) and do affect the engine alignment, but the swingarm pivot shaft is responsible for almost all of the alignment, through it's relationship with the frame, and engine, and swingarm. (This is shared by the FLT platform) A tube-frame Buell doesn't have this major "Locating device", and the tie-bars, and ONLY the tie-bars, maintain the relation ship of the front wheel and the rear. You can remove the tie-bars from a Vrod, and it will be a little soft, but still rideable. Pull the tie-bars on a tubeframe Buell, and it's a Flexi-Flier.  As I asked before, How do you know what "right" is for your alignment? | ||

Werewulf |

how do you know its right from the factory? the buell is the same as a v-rod, its NOT a pivot like you show...ive been into this v-rod thing in depth, when my second v-rod started eating tires...the entire frame is aligned with the front tie-bar on a v-rod.. on the buell, if the turn-buckles have to be wrenched tight, then something is askew with the motor alignment or the frame.. this could possibly be why some bikes suffer front mount failure... | ||

Werewulf |

everything ive read about buells, says that pre-load plus vibration equals failure! | ||

Jos51700 |

And for the record, I can see how adjusting the tie-bars on your Vrod could make positive changes. I've done dozens of chassis alignments on VRods, FXR's, and FLT's through the years. The factory doesn't always get it right, even with a swingarm pivot to help line things up. However, on the tube-frame Buell, without precision measuring equipment (Computrack), just changing the tie-bars on a whim can only cause or add to misalignment. You'd be mighty lucky to get all three axis adjusted properly. | ||

Werewulf |

well then, ill just name my bike the "florida crab"! | ||

Jos51700 |

Failure of what? The tiebars have to be loaded. In the example above you can see how the front tie bar takes all the side-to-side load of the rear wheel (And engine) and keeps it in check. Ditto for the other bars. If you were to look at the bike from the rear, can you see how the length of the top bar keeps the wheels in a vertical alignment? if the motor tilted one way or the other, the rear wheel would also tilt, and not be in vertical alignment with the front. | ||

Jos51700 |

"well then, ill just name my bike the "florida crab"!" I've always called it "dog-tracking" (The rear is never in-line with the front, but I'll now call it "Florida Crab Walking"! "everything ive read about buells, says that pre-load plus vibration equals failure!" This is true, for parts that are bolted down solid (Like the cheesy die-cast mounts bolted to the front head, for which the Stenzel brace is a good idea). Except that tie-bars move, so they can't technically be preloaded. When I said preloaded earlier, I guess I should've said "Loaded in compression". |