| Author | Message | ||

Bkarle |

ARE THERE ANY FAQ PAGES ON TUNER PRO RT ? I NEED TO DO A TPS RESET AND HAVE NOT USED THIS PROGRAM YET . THANKS 2006 ULY | ||

Froggy |

Here you go - http://xoptiinside.com/yahoo_site_admin/assets/doc s/Using_Tunerpro_RT.15590439.pdf | ||

Pagprivat |

I have hooked Tunerpro up with an EBR ECM with this manual, and it works pretty good. Logs, reading etc. I have found two issues, don't know if it is my laptop or a common problem? 1. Occasionally it seem to suffer some corruption in communication, the dashboard meters "flickers". The needles just goes to max for a split second, then go back to normal? Inconsistent frequency, sometimes as frequent as every 2-3 seconds. 2. TPS reset command returns with an error. I have not found out anything here yet, and to this date I am not sure if I have really been able to reset the TPS on the EBR ECM. Anyone with experiences? | ||

Bkarle |

Thanks for the help . | ||

Pagprivat |

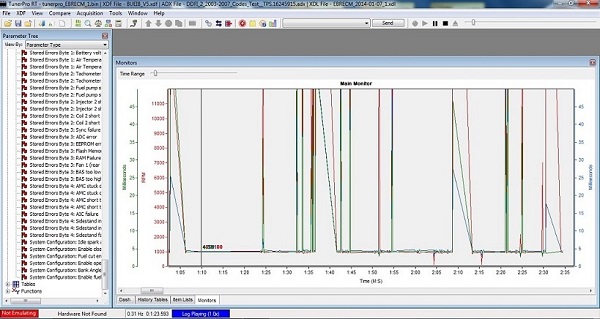

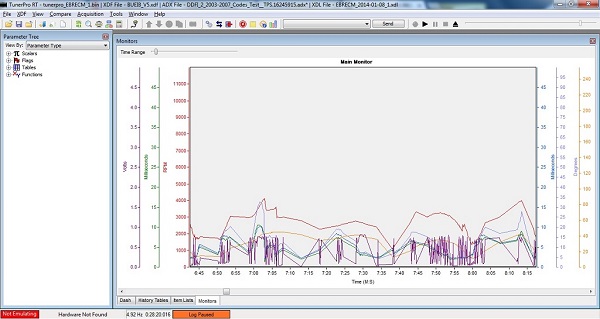

Following up on this, my problem with communicating with the EBR ECM got worse and worse with Tunerpro (RT V5). It came to a point rendering the data almost useless, this is a printscreen of how it looked:  The fix is here: http://forum.tunerpro.net/viewtopic.php?t=2215 After inserting the "listen for silence" in the definition file (.adx which I downloaded from xopti) 99% of the problem is gone, and the last few spikes (had 4-5 over a 1/2 hr ride) I guess I will either live with, or tweak the time of 20ms just a little. This is how it looks now:  My other question is, does this look like normal O2 behavior? (purple curve) To me this looks like pretty random behavior, and probably up for a replacement? (Message edited by Pagprivat on January 08, 2014) | ||

Uly_man |

"My other question is, does this look like normal O2 behavior? (purple curve) To me this looks like pretty random behavior, and probably up for a replacement?". It is hard to see from the picture but it is a FACT that your setup is wrong. The O2 sensor needs to get past an engine temp of about 100 C before it has a stable output. TP is a generic prog and you need to set up the numbers in your own named .adx file as the basic ones are not right for the bike. You need to go into adx edit and set the high and low limits for each output/function given the bike/car. In this case it would be something like 0.0 to 1.2 volts for the O2, 0 to 8000 rpm, 0 to 240 C for engine temp, 0 to 30 C for air temp, 0 to 16 volts for battery charge, 0 to 250 C for oil temp and the same for all the other things as well. You can have it as you have now but it makes it VERY hard to read what is going on. Also pick only, on the graph/box, the functions you wish to monitor at the time. On a logged run all the data is stored so you can go back and pick out what you need at any time. You will also need to setup the "dash" functions as well if you want it to work right. (Message edited by uly_man on January 10, 2014) | ||

Pagprivat |

Thanks for the input Uly man. Indeed, I'm still exploring all the possibilities around in TP, finding new things almost daily  The O2 sensor has the same behavior all over the temp scale though, about 1,0 V variations - cold as well as during normal operating temperature. It seems random, cannot find that the variations follows any pattern or any other signal as that I would think is associated (tps, pw, etc.) I already got a new sensor, so I've decided to drop the engine in the weekend (have some other things to do too) to replace it. Will be interesting to make a new log after replacement to see if there is any difference. | ||

Uly_man |

"It seems random, cannot find that the variations follows any pattern or any other signal as that I would think is associated (tps, pw, etc.)". The O2 sensor is not associated to anything. It sends a 0.0 to 1.0 volt signal to the ECM through a single wire with the Earth via the header. From cold the signal should be stable at about 0.85 volts and once hot enough runs between about 0.05 and 0.85 volts. As best as I can see yours is working fine and you will get the odd saw tooth to the log as well as the odd data glitch. It is normal. The bike WILL run without a O2 sensor but the fueling will stay the same IE Not change the AFV due to changing conditions. Is your EBR ECM mapped, by EBR, for a 07 bike with a Drummer can and what are you trying to do with TP. Do you have running problems, faults, etc. | ||

Pagprivat |

Dropped motor in the weekend and changed the O2 sensor. The main purpose for rotation was to replace the header seals which were leaking, but it was very convenient to change the sensor at the same time... The ECM has been calibrated by EBR, for a 07 with a Drummer, + the fuel in Brazil, where I am. (Even premium fuel contains 24% ethanol down here). We discussed this slightly prior to calibration, and the guys at EBR tech support said that it might need some more fine tuning on fuel/timing maps in order to have it optimized to these conditions. I have some low RPM surging and an occasional CEL, so I guess what I'm doing right now is stumbling around in TP to see if I can learn something  Haven't had time to do any logged rides after rotation yet, I'll see the next couple of days. (Message edited by Pagprivat on January 13, 2014) | ||

Uly_man |

"Even premium fuel contains 24% ethanol down here". Man that is a lot. I would see if you can pin down the reason for the CEL coming on as there will be one. It could be anything and if you have not done it yet clean the paint off the Earth the wires are bolted to the rear sub frame. It caused no end of problems on my 06 bike. Good luck. |