| Author | Message | ||

M1combat |

For anyone that has gone through the rigmarole of safety wiring an XB... Do you have pics of how you did it and maybe some insight as to what you may have done differently and why? I'll be getting a salvage titled bike some time in the near future and it'll be a race bike. Thanks in advance. | ||

Jackbequick |

M1combat - Check out this link: http://www.avweb.com/news/maint/191176-1.html The materials and techniques used in the aviation community simply have been tested and proven over a long period of time. Everyone has an opinion of the "right way to do it" but the aviation community has a tendency to follow up on it when it turns out that it did not work. Their practices are subject to inspection and result from a lot of stuff that was learned the hard way. The section on Safetying in Chapter 7 of the practices will answer most of your questions and get you off to a good start. It has some excellent examples and illustrations in it. That whole chapter is pretty neat, check out the section on using a torque wrench with "adapters" like crowsfoot wrenches. Great stuff for those of us that like to worry about the details. Jack | ||

Blake |

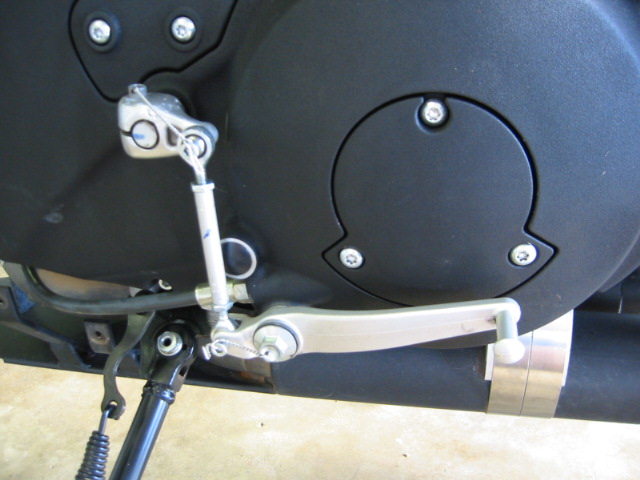

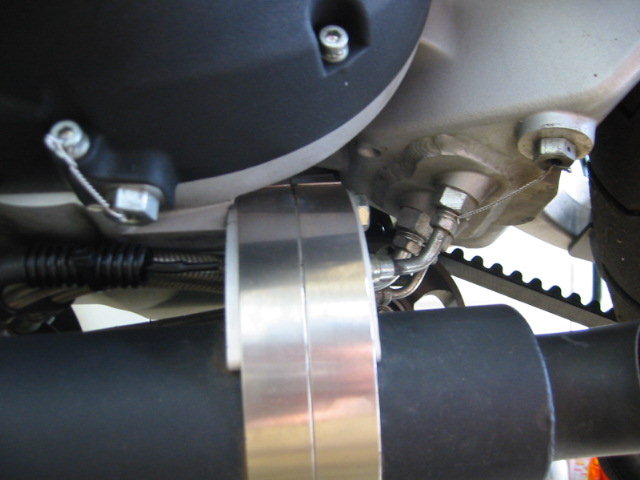

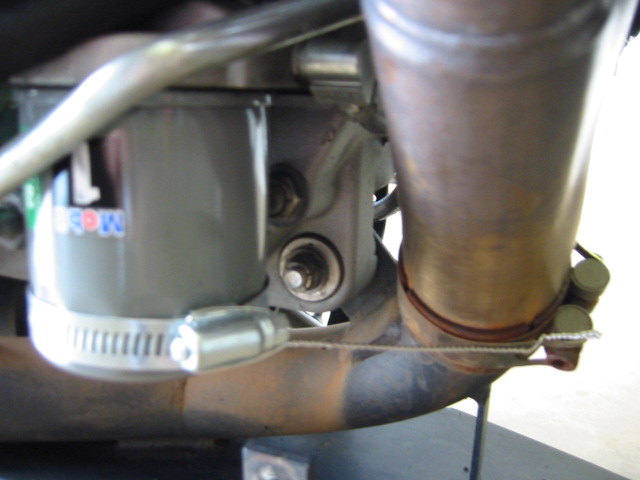

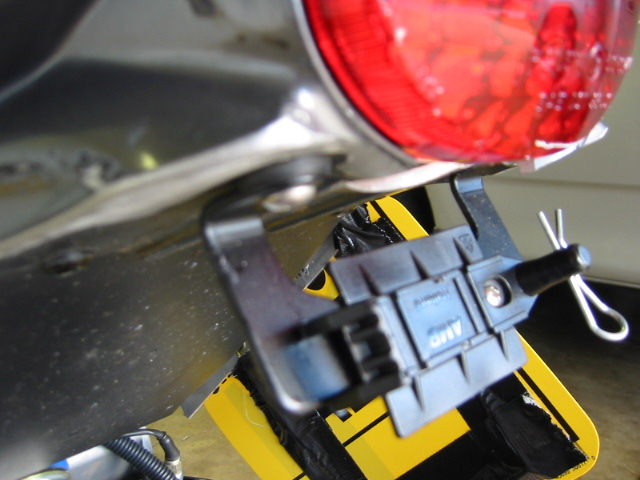

Because I like ya...   Front Axle Safety Wiring Rear axle is done similarly but use the little slot in the swing arm to pass the wire through back to the pinch bolt.  Front Axle Pinch Bolt Safety Wiring  Oil Cooler and Oil Line Safety Wiring  Shifter Safety Wiring  Primary and Oil Drain PLug Safety Wiring  Oil Filter Safety Wiring  Front Caliper Bolt Safety Wiring  Steering Damper (LSL)  Transponder Mounting Bracket  Oil Filler Cap http://www.badweatherbikers.com/buell/messages/32777/44334.html Thank Keith (Skully) for all but one photo above and Mark (Englishman119) for the front axle photo. More race prep info in Keith's logbook in the Tale Section. | ||

M1combat |

Very nice Blake. Thanks a bunch. I'll be sure to read the Aweb links as well as I'm a detail oriented kind of guy. Thanks for that too  . . | ||

Benm2 |

Buy lots of bits. Go to MSC Industrial or McMaster Carr & buy 20-30 of them (1/16" bits) You'll break lots. Good luck! Oh, one more thing, keep a close eye on: 1. Primary drive nut 2. exhaust stud nuts | ||

Diablobrian |

First of all, buy a bunch of 1/16" drill bits. You will break a lot of them. With holes this small center punching is an absolute necessity. Exhaust nuts are also supposed to be safety wired. Yes it is a pain to do. We also have the rear brake rotor bolt safety wired. Do not forget to have a catch can for your fuel tank vent, and crank case vent. You may want to safety wire your grips to keep them from moving during a race. | ||

Diablobrian |

If you have an exhaust that is held together with springs those need to be safety wired as well. | ||

Rubberdown |

Great thread! What's the best procedure for drilling the bolts/nuts and such? Any tricks? | ||

Henrik |

I haven't drilled a lot of nuts & bolts, but enough to get frustrated  and I'm even using a drill press with a good clamping vise. If I knew I would be doing a lot of this, I'd probably invest in a safety wire drill jig: and I'm even using a drill press with a good clamping vise. If I knew I would be doing a lot of this, I'd probably invest in a safety wire drill jig: http://www.streetandcomp.com/mcart/index.cgi?task=show&cat=Safety+Wire+%26+Tools There are others out there, so do a search. This is a jig from the aircraft industry, and I'm not sure if it'll allow you to drill flat-to-flat across the corner, but it looks like a nice unit: http://www.irvansmith.com/catalog2/parts/safety_wire.shtml Also, keep and acid brush or similar in a cup of cutting oil (I used WD40 and that was ok as well) nearby and keep lubing up that drill bit. More info: http://www.sportrider.com/tech/146_0002_hand/ Henrik | ||

Jackbequick |

Henrik - WD-40 is really a poor drilling lube. The funky smelling, sulpherized, yellowish colored, threading oil used by plumbers is much better stuff. You can pick it up in a small bottle at Home Depot usually. The acid brush is the perfect tool for putting it on though. As as gunsmith I did a lot of drilling on harder metals. Ideally, you would have a jig or fixture with a carbide drill bushing sized to the drill to keep the drill from deflecting under pressure. It looks like that is what the ivansmith tool uses. Carbide drills are not ALWAYS a good bet for home guys as they break too easily if you do not have a rigid setup and a good drill press. On SS bolts try using a little slower speed, a little heavier pressure, and don't back off once the drill is cutting or the surface may work harden and smoke your drill. Once the material gets that shiny look the drill is finished. Hopefully you can get a cut started again with a new drill. Jack | ||

Henrik |

Thanks for the info Jack - WD40 was what I had within arms reach  I'll go to Home D and look - or sniff - for threading oil I'll go to Home D and look - or sniff - for threading oil  Henrik | ||

Blake |

Don, My pleasure.  | ||

Slaughter |

Heads up on a couple tricks on those allen screws: Put a washer under the head. It lifts it out of the hole enough to cleanly get a hole drilled below the top of the socket head. Otherwise you end up drilling in at a funny angle. The washer lets you drill straight across. On the caliper bolts, that is especially handy. | ||

Rc4man |

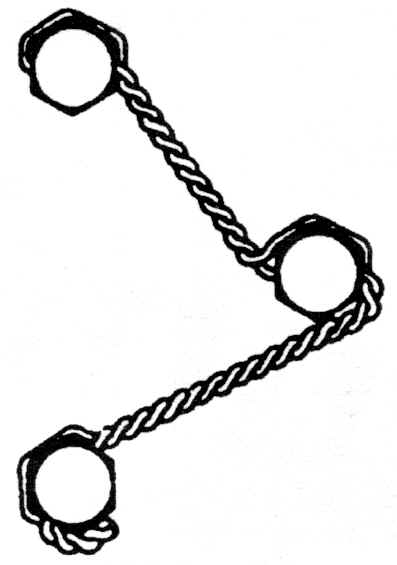

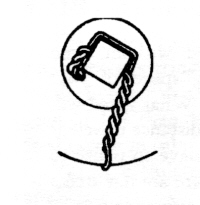

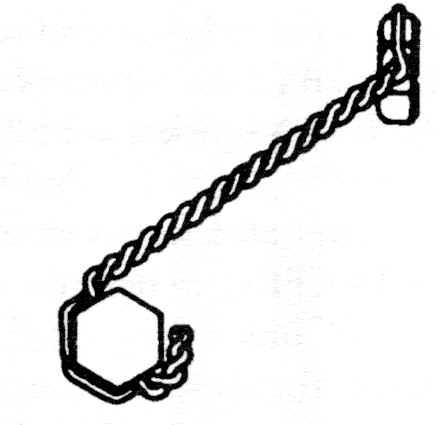

There are multiple resources for proper safety wiring techniques available online and generally even from Robinson when you buy a set of wire pliers. Basic premise is to arrange the pull direction of the wire so it is always pulling the bolt head in the tighten direction. Examples      | ||

Doitindark |

How did you guys drill a hole in your oil drain plug and the primary drain plug? I just wired up the bolts that held on the oil cooler by hand, I don't know how I'm going to drill the thick drain plugs. | ||

Bud |

i drilled the plugs during a oil chance, it's not hard it's not high graded steel. i drilled all the other bolds using a vice and a pressdrill, but the plugs i did with a battery drill and freehand , was no problem. ps. a tip, use a K&N oil filter, it come's with a magnet and a lockwire hole on the bottom gr,b (Message edited by bud on March 25, 2006) | ||

Buellgirlie |

coooool. i learned to do this tonight on my new racebike! drilled out the primary drain and wired up that and the oil filter  D |