| Author | Message | ||

Heavy18 |

Okay, well I've waisted several hours of my life on the internet to no avail... (Bike is a 2006 Uly) The fork seals I replaced last fall, the right side is leaking again. I've been told to replace the guide bushing as well this time around. Last time I flipped the copper crush washers so those need replacing as well, I figured I might as well do the slide bushings while I'm at it... I can't find a rebuild kit ANYWHERE when searching for 2006 Ulysses/XB12X, Showa 43mm, etc. So I head on over to St Paul website and I put together my own rebuild kit with seals, dust caps, washers and 2 sets of bushings, I try to checkout and WHAMMO - I get a message there is a problem with my shipping address... So I try to checkout with PayPal and get the same error. So, I guess the rumors about not being able to sell outside of your area are true? Does anyone have a link to a 3rd party fork rebuild kit for the 2006 Uly Showa 43mm front fork?? Second question: I bought some valve cap TPMS transmitters to try out. The rear fit fine but the front makes contact with the brake caliper. So I thought "if I can just bend the valve a tiny bit out, it will clear..." I'm telling you I almost had it! Of course the operative word here is *almost*. So yeah, I need a new valve stem... Which I also planned to buy from St Paul... I can find OEM stems on eBay for $25 - feels excessive. I've read posts here about trying to get a right angle stem to work. One post talked about milling the rim (I'm not interested in that) but another talked about a way to somehow extend the threads on a right-angle stem to get it to work... Can anyone make sense of this post? You can make the part tha goes in to the rim longer by using an old stem make a 4 mm thread and use a hollow 4mm Allen screw. That way you have the stemmlong enough, I had it done for the Ulysses and worked fine with no issue It is from this thread. Well, I appreciate any help out there! | ||

Pushr0d |

It's been a while, but I think I bought all the bits from the local HD dealership. They can get quite a few Buell Part Numbers. Nothing special about the fork seals - they're pretty generic. Don't get the 'Lifetime' ones - they aren't. My front wheel has a 90 valve on it, and I had a 90 put on my back wheel. Can't help with the TPMS clearance issue. | ||

Heavy18 |

Thanks Pushr0d - do you know what valve/brand you had put on the rear? If I can get a 90 on then the TPMS cap will fit. | ||

Lew360 |

I bought all my fork rebuild parts from St. Paul had no problem. I just tried to order a set of plug wires and had no problem. I really don't know why you can't order for them. I'm in MD. | ||

Pushr0d |

Heavy18 - the bike shop that mounted the new tire had them - probably a no-name part. | ||

Littlebuggles |

I think I have a couple valve stems. I can look through my leftover parts from the CityX I built up last year. If you decide to skip the pressure sensor pm me and I will dig up one of those stock stems for you. | ||

Mark_weiss |

Most 90 degree valve stems are aluminum. I don't know that I'd try dangling a TPMS transmitter from the end of that. | ||

Heavy18 |

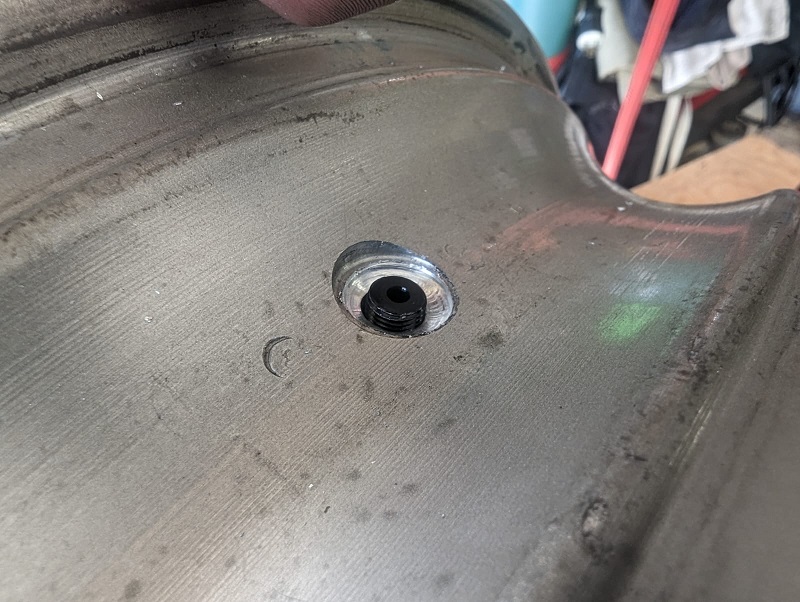

Thank you for the generous offer Littlebuggles, I think I'm all sorted on the Valve Stem. Update: my local HD dealer had the guide bushings in stock and put the slide bushings on order for me. I remeberd I don't need the crush washer since you don't have to take that off on these inverted forks. I plan to measure the new bushings and figure out what generic PNs work, they are Showa forks after all so I'm sure they are both available under non-Buell/HD PNs. I bought some ~90* valve stems on Amazon and got them to work. I'm slightly hesitant to post up my methods here since I'm sure it will not be acceptable by some but ... What the heck! The wall thickness at the valve stem hole is ~10mm due to the plateau built up on the hub side. The thread length of the stems I bought is ~11mm with an O-ring in there. The outer dimension of the nut on the new stem is ~1/2". I work in manufacturing, I'm not an engineer but talking to a coworker one day he told about a time at an install where they where putting in some structural supports and he asked the lead structural engineer how many threads they needed in the nut to support the load (I guess they were getting worried about tolerances). Anyway their working load was over 1k lbs and the answer was 3 threads... All this setup has to do is provide enough pressure to engage the O-ring enough to handle 45ish max PSI... According to Google: The recommended torque for standard aluminum wheel valve stems is 7 to 11 ft/lbs. So armed with that in my mind I used a 1/2" drill bit and clearanced the tire-side of my rim enough to allow for 4 threads of engagement. The nut has a tapered head so I flipped that around to take advantage of the slightly tapered hole the drill bit made. (I plan to use some blue locktight on the nut; the stem and nut are aluminum.) I have pictures but have been having issues posting ... I'll try those separately. | ||

Heavy18 |

Sorry, I neglected to clean off the soapy water in the first pic:      | ||

Heavy18 |

Most 90 degree valve stems are aluminum. I don't know that I'd try dangling a TPMS transmitter from the end of that. Mark_weiss I know what you mean and I have my concerns since I've been known to ride at 115mph+ for sustained periods on desert roads ...  BUT ... that is the whole reason for this project! So I'll be mounting them up and reporting back. In the end I believe it will be just fine, these valves have a sufficient wall thickness and the TPMS is feather light so even at excessive speeds it really should not be an issue. As well there are several riders using them currently on right-angled valves without incident. | ||

Heavy18 |

Quick updates Valve stems: No issues to date. I've had the right-angle stem installed on my front wheel for about a month now and put 1,100+ miles on it in that time. I've had a couple sprints up to ~110 mph along the way but mostly cruising between 60-80 mph. I have it clocked so that it's not perpendicular to the rim, nor parallel. I feel like this gives me good clearance for the TPMS while not sticking out too far (pic below). I bought the TPMS on Amazon: Leepee Bluetooth 5.0 Motorcycle Tire Pressure Monitoring System. There is an app you download to your phone and the sensors connect via Bluetooth. The app shows tire pressure and temperature. It's a decent setup and works well, however, I do have two complaints: (1) It takes a few minutes to sync the sensors to the phone and there is no indication of when that happens. The app shows you old data from your last ride until it syncs. So I have to take note of what the pressure/temp says when I start the app and then see when it changes to know when it is live data vs stale. (2) When I have the app running it REALLY drains my phone battery (I have a Google Pixel phone). If I have my phone plugged into a charger while running the TPMS app, Google Maps and my Sena communicator at the same time, my phone won't charge it just maintains. So I open the TPMS app, check my pressure, leave it running for a while to watch my tires warm up and pressure stabilize, then I kill the TPMS app. Overall for the cost and effort of everything I'm happy. It's nice to be able to check my tire pressure at different times on a day-long ride without breaking out my gauge and rotating the wheel to the right spot. Fork bushings: after replacing the slide bushings, guide bushings, fork seals and dust covers, they seem to be holding the oil. I do have a slight weep on the right side but I had an *incident* on a dirt road and I suspect I need to run my cleaning tool around the seal on that side.  Pic of the valve stem and TPMS:  | ||

Doz |

Just a quick note about those guide/slide bushings: they are cheap! Like under ten bucks! May as well put in new ones while the bike is torn down. Don't forget the fork oil, type E. |