| Author | Message | ||

Jmartz |

600/62.5 = 9.6 Displaced volume into final volume | ||

Blake |

Jose M.: Your compression ratio (CR) formula is incorrect. CR is calculated by dividing not "displaced volume" but initial volume (V1) at BDC by final volume (V2) at TDC. V1 is equal to the displaced volume (VD) plus V2. Gettin' algebraic on the issue gives us the following... Given that VD=601.5 cc and CR=10... V1=VD+V2 CR=V1/V2=10 We have two equations and two unknowns, so we can solve for V1 and V2 as follows (I sound like a friggin algebra teacher, yech!)... Arranging the compression ratio equation to solve for V2 we get... V2=V1/10 Substituting for V2 in the other equation we get... V1=VD+V1/10 simplifying... V1=VD+0.10*V1 Solving for V1... 0.90V1=VD V1=VD/0.90 V1=601.5/0.90 V1=668.3 cc Then solving the CR equation for V2 we get... V2=V1/10 V2=668.3/10 V2=66.8 cc JoseM: I guess the darn factory wasn't lying to you after all? Ain't math great?  Blake | ||

Sportyeric |

That's all very well but do remember that we're mixing clearance measurements in thousandths of an inch and volume measurements in cubic centimeters so make sure you do all the necessary conversions. You are from the country that crashed a rocket on Mars for getting mixed up with the metric system. (This from the guy that doesn't have a pocket calculator while he's typing on a computer.) | ||

Sportyeric |

But seriously though. The "Handbook" says the S1 has a squish area. I don't think it does, unless the diameter of the combustion chamber is slightly less than 3.5". I forgot whether I ever measured it. Comments? Except where a flat-top piston meets a bath-tubbed head, does it matter if you shave the head, use thinner gaskets, or mill the bottom of the barrel? The effect should be the same. But if you took 20 or 30 thou off the barrel, would the liner contact the flywheel or the con rods? Can the lifters adjust for the change in cylinder length? There is, what? 100 thou top to bottom in a lifter. Does it matter if it is operating at the bottom 20 thou rather than the middle? Am I just lucky? Swede. other than tightening the clearances, as mentioned in general, the bible doesn't address the S1 directly as I recall but I'll give it another read later and maybe copy you some relevant parragraphs by email if I can find the time. Thunderstorm heads would best benefit from tightening the clearances because they definitely have a squish area. New subject? Or was it old before I got here? Base gasket leaks. The Cure? Does it work? Does it restrict flow of oil? Is that passage that causes the leaks in the supply end or the return? Nice work on the crank vent stuff, Aaron. Thanks. | ||

Aaron |

Eric: Man, great questions ... I'll give my take ... maybe Pammy will step in here too ... The "Handbook" says the S1 has a squish area. I don't think it does, unless the diameter of the combustion chamber is slightly less than 3.5". I forgot whether I ever measured it. Comments? You're right, there's really no effective squish on a flat-top open chamber Sporty. As you point out though, The S1W motor has a squish between the chamber wall and the side of the dome. Not a very tight one, either. We're getting a full bathtub chamber on the XB. Except where a flat-top piston meets a bath-tubbed head, does it matter if you shave the head, use thinner gaskets, or mill the bottom of the barrel?" Personally I wouldn't run the piston any closer than about .020 to the bottom of the head. Otherwise you're counting on the chamber being at least the diameter of the piston, *and* being well centered, neither of which is guaranteed. Keep in mind that the chamber wall is is angled and starts getting smaller in a hurry. You don't want to stick the piston up there. Plus, what if you ever want to bore the cylinder? Now you ARE bigger. Bottom line, I treat it as if there is a squish band. The effect should be the same. But if you took 20 or 30 thou off the barrel, would the liner contact the flywheel or the con rods? I've trimmed cyls .020-.030 a couple times and checked that clearance and never seen an issue. I generally prefer to cut the cyls rather than use thin gaskets. Gasket leaks suck. Can the lifters adjust for the change in cylinder length? Maybe. Beyond about .040 to .050, I stick in shorter pushrods (best place to get them is Smith Bros). I've had people tell me of troubles with valves not closing at as little as .055 of total height reduction. My preferred solution for base gasket leaks is Pigtails with James steel base gaskets. The Hayden thing is a rip-off and doesn't work. The supply side is the pushrods, there's no supply up through the cylinder. Best of luck, AW | ||

Aaron |

BTW ... 2.54cm to an inch is an exact conversion. Just take ci and multiply it by 2.54 cubed. I don't understand the 1203 thing. Seems to me like 3.498x3.8125 comes out to 73.277ci, which is 1200.799cc. Even if you call the bore 3.5", it comes out to 1202.173cc. Someone explain this to me? AW | ||

Mikej |

"If we have to explain it, you wouldn't understand"  Maybe they're measuring the total cylinder volume, as opposed to piston stroke length, adding in any squish and clearance, maybe sort of as an ego boost of sorts. 1203 sounds bigger than 1201 or 1200.7 or 1202. Or maybe someone's birthday in the Davidson family is on December 3rd? | ||

Blake |

Could 1203 cc be a "hot" displacement accounting for expansion of cyl dia at operational temperature?  | ||

Sportyeric |

Thanks Aaron but there's no need for luck. I participate only for the sake of others. Mine's already done and won't be re-done until it's a major rebuild while I ride my XB. The only thing I'd change would be the thin base gaskets. I think anyone who has the cylinders off should use the "Pigtail" or equivalent. I can't get on top of my base gasket leaks, although the current one is self-inflicted.Leaks do suck. I assumed a squish without seeing one but I never thought about re-bores. Good point! As it relates to Swede, though, the S1, 91 hp head, which is what I have also, doesn't have a squish, right? The S1W is Thunderstorm and has a good one, or a potential for a good one, yes? Swede, I gave some details of my improvements, inspired by the "Handbook", in the Cool Pics section a couple of weeks ago. I'm happy with the results. My S1 motor in the heavier Sporty frame will firmly beat a stock S1 in a roll-on at any rpm range. (I can't tell you whose test ride we compared it with.) | ||

Aaron |

The S1's chamber is smaller, yielding a 10:1 compression with the flat-top pistons. The T-storm's chamber is also an open design but it's larger and uses a domed piston to get 10;1 and the squish is between the dome and the chamber wall. But, owing to it's mass-production environment, it's not a real tight squish, there's room for improvement. Good luck to "others"! AW | ||

Anon_R |

Aaron, Don't forget to add in the head gasket volume for total displacement. R | ||

Aaron |

Head gasket volume for total displacement? You lost me ... what's head gasket volume got to do with displacement? Has a bunch to do with volume above the piston, as does the chamber volume and dome volume and valve relief volume and deck height. But displacement? AW | ||

Swede |

Nice bikes, Eric. I think that the winter will bring serious porting of my existing heads, domed pistons, HSR42, losing the rev limiter and harder valve springs. That should hopefully be enough to give me 100+ rwhp's... With an extra 30 when I hit the nitrous. | ||

Sportyeric |

That's why they call it laughing gas. | ||

Blake |

Swede: You expecting this bike to last? | ||

Peter |

AnonR and Aaron, I was always under the impression that displacement was the swept volume of the cylinder. I got my truck license here a few weeks ago, and in that theory course, they say it also includes the combustion area. I argued my point but if you are saying the same "R", were they right? PPiA | ||

Aaron |

Peter: you're kidding? They said chamber volume is displacement? Sorry, ain't buying it. A think Anon R, assuming it's the same Anon R, was yanking my chain. AW | ||

Mikej |

He wouldn't do that, would he? Nawwwwwwwww. | ||

Sarodude |

Does anyone in the HD or Buell world care about head temps? If so, what's a good range for what ambient conditions? Who makes appropriate guages? I ask 'cause I had my Blast motor poop out on me last weekend. Felt kinda like some sort of compression problem. Made me wonder if I'd had a cold stick. That in turn made me wonder about CHT. Anyway... -Saro | ||

Swede |

Blake: Not forever but it will give me good fun for quite a long time, I expect. Remember that N2O only is active very short time spanns. My 10oz bottle will last about 20 secs. Planning to double that, but still very short times. Only to be used in the unlikely event of being outrun be an other bike should appear...  | ||

Blake |

Saro: "cold stick", "CHT"?  Please explain. Please explain. | ||

Hans |

Hi Peter, Wonderful trip you made. Good to see you back in one piece. Your brain is still not working very well after that high altitude sickness without eating or is your Dutch not well enough to understand. How could you pass that examination then? You bribed them with free tickets for the show? Our engine has a diplacement (Dutch= cylinderinhoud) of 73.4 ci And the bore is 3.5 inch Stroke is 3.8 inch Surface piston is 1.75 x 1.75 x pi total displacement of two clinders is 2 x stroke x pistonsurface =2 x 3.8 x 1.75 x 1.75 x 3.1416= 73,12 cu inch. Mmm close, but not exact. Metric: Bore 88.8 mm Stroke 96.8 mm displacement: 2 x 96.8 x 44.4 x 44.4 x 3.1416 = 1199 cc. Also close to 1203 cc in the Service manual however not exact. It is closer to the 1197 cc wich is printed on my official owners document. But the space in the combustion area has sure nothing to do with the displacement. Welcome back and see you in Zandvoort. Hans. | ||

Sarodude |

CHT stands for Cylinder Head Temperature. A cold stick is what happens when a silly buffoon (the moron writing this post) puts heat into a motor too quickly and the differences in expansion rates between the piston and cylinder cause a siezure of some sort. Being totally new to ANYTHING HD, I don't even know if the blast has an iron cylinder or an aluminum cylinder with iron liner or nikasil plating or.... Anyway, an all iron cylinder would make the worst scenario as it not only expands at a lower rate than aluminum but also heats / cools slower. -Saro | ||

Peter |

Hans, If I remember, I'll bring the theory book with me to Zandvoort and you can tell me if the instructor translated it wrong for me or not. PPiA | ||

Anon_R |

Displacement= Bore x Bore x stroke x .7854 x number of cylinders. Playing with numbers...a little. Bore 88.920mm service wear limit on standard bore from service manual. Stroke 96.82mm taken from "service manual" 88.92 x 88.92 x 96.82 x .7854 x 2 =1202.4994cc Rounded just a touch...1203cc Sorry Aaron, experienced inner-cranial gaseous release (brain fart) there for just a moment. I was thinking about compression ratios there. R | ||

Blake |

Saro: Buells all come stock with iron sleeved aluminum cylinders. Thanks for the terminology lesson and acronym translation. | ||

Sportyeric |

Swede has raised an interesting question: if you have S1 heads , and you are going to spend money on new pistons and head work (whether you are rebuilding or hot rodding), would you get a bigger bang for your buck just buying Thunderstorms, or would the S1 heads be more economically reworked to the same effect. BTW, my initial CR estimate that started this whole thing was .3 increase. If anyone noticed that this number, multiplied by 2.54 equals Aaron's calculation, that's just coincidence. Canadians deal with metric and inches all the time because we often have to cope with Americans and the French. I don't know where that .3 came. | ||

Sportyeric |

Swede has raised an interesting question: if you have S1 heads , and you are going to spend money on new pistons and head work (whether you are rebuilding or hot rodding), would you get a bigger bang for your buck just buying Thunderstorms, or would the S1 heads be more economically reworked to the same effect. BTW, my initial CR estimate that started this whole thing was .3 increase. If anyone noticed that this number, multiplied by 2.54 equals Aaron's calculation, that's just coincidence. Canadians deal with metric and inches all the time because we often have to cope with Americans and the French. I don't know where that .3 came from. | ||

Hoser |

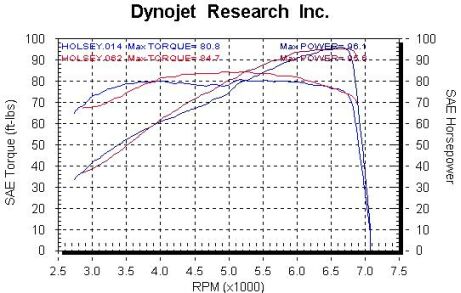

Fella's: Here's an experiment I did when the Thunderstorm heads became available. I already had modified my S1 by porting & milling the existing heads ,milled the cylinder bases ( on the lathe ). The stock header pipe ( 2" )was combined with a Vance & Hines slip on muffler , a stock carburetor w/3" K&N filter mounted on a hand made air cleaner , screamin eagle "Q" curve ignition module ( same as pro series ). A second configuration on the same bike using "Tstorm" heads that were ported and milled , "Tstorm" pistons on new as delivered cylinders , thin head and base gaskets , 2.5" pro series exhaust , the rest being the same as above........................................... Here's how it turned out  Peak HP numbers were very close , TQ was increased due to the higher flow/cylinder fill of the "Tstorm" heads , Mid range was meatier using the "Pro Series" 2.5" pipe. Jeff | ||

Hoser |

All: Upgraded part for 2002............................ The sprocket shaft seal (crank ) is now a double lip seal ,a new installation driver is required. Parts books are not out so I can not provide a part # yet. Jeff |