| Author | Message | ||

Rick_a |

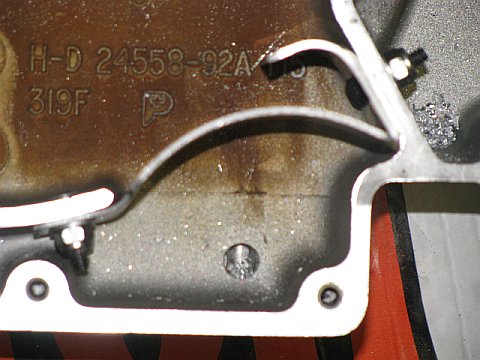

Such a simple little bugger but such a pain to install.  My motor build is almost done (new style crank, headwork, etc), but a split locknut on S&S pushrods has halted progress for now.  Note the fancy engine stand. Eventually it'll be back in here  ...and it'll look something like this:  | ||

Puddlepirate |

What are the specs on your motor? | ||

Rick_a |

Andrews N9 cams, Mikuni 45, Rev-Tech roller rockers, S&S quickie pushrods and lifter travel limiters, Dyna S Dual fire ignition, new '00-up style Buell flywheel assembly, Zipper's windage tray/flywheel scraper, Revolution Performance 1250 kit, Cycle Rama ported XB-style heads, Zipper's Pro Flow oil pump. It made 96RWHP and 82ft-lbs torque before the headwork, so I'm looking forward to finally braking the 100HP mark. (Message edited by Rick_A on July 08, 2008) | ||

Bad_karma |

Nice, looking forward to the end results. Joe | ||

Puddlepirate |

Sounds like you should definitely be over 100. When do you plan on having it all back together? | ||

Rick_a |

A few days after I get a replacement pushrod locknut she should be rollin'. BTW your Sporty looks tits with that Buell front end. | ||

Bluzm2 |

Rick, I love the "spectator" in the window! | ||

Rick_a |

Yes, he likes to follow me around and "help" by smacking my tools against expensive parts. He also points at various components and asks "this?" | ||

Buell_bert |

Curious but what is in the first pic that is a pain to install | ||

Rick_a |

The setup and clearances. The inner case surfaces are a little irregular and both sides had to be ground to match. Both pieces also had to be trimmed for width. It has to have a .015"-.020" clearance (IIRC) with the flywheel and it's a bit of a trick to get the scraper to keep that clearance once bolted in place. There was a lot of time spent with a grinder and file. There are also no templates or measurements for drilling the holes, and drilling into very expensive parts can be a little nerve racking. | ||

Capndoug |

The guy that will be lapping my pinion warned me not to install a scraper. He has had problems with leaks occurring over time, as the front bolt goes through the outside surface of the case. One instance he said it shifted position and caused some damage. So he only recommends them for race engines. Looks like a nice careful installation though. In addition to the nylon locknuts, I would use thread locker on a vibration intense application like this. Did you thread the holes in the case, or just drilled? | ||

Rick_a |

I did use thread locker, but I did not thread the holes. The thought never occurred to me. That would've been great on those two scraper bolts going through the transmission. I can't see much oil gettin' through there...but I know I will be keeping a close eye on oil levels for some time. | ||

Capndoug |

The installation I was told about the windage tray had fasteners through the front of the case. So, leakage would be much more of a problem than a transmission case hole only. | ||

Hoser |

I've installed quite a few of those zippers scraper kits , It might be a good idea to use washers with captive "o" rings , like on early evo big twin derby covers. To do that , I used 1/4" fasteners on the two bolt locations that enter the transmission area , fluid transfer can occur if you fail to get a god seal here. |