| Author | Message | ||

Bobpaul |

Just turned over 20k miles on the bike. Mostly stock. I'm planning some major service, pulling the heads, and wondering if I should change out the bolts mounting the bracket to the front head? There's been lots of pictures on this site showing broken bolts which is why I'm asking. | ||

Henrik |

There was a service bulletin re-write of the installation instructions for those bolts. Not sure where it went, but it might be somewhere here in the KV. There may be a mention of whether reusing bolts is ok. Given the history of those bolts breaking on occasion, I'd probably replace them if it were me. Henrik | ||

Court |

Never reuse the bolts. There is a very detailed procedure for installing the new bolts. Make certain you have the procedure for YOUR SPECIFIC bike. Use new bolts. Follow it. That's keepin' it simple or what?  | ||

Bomber |

Bob -- I'd leave em alone unless you need to change them for some reason -- if you do need to change em out, Court's advice is good, sage, and wise counsel | ||

Blake |

Fully torqued/preloaded high strength bolts should not be re-used. During full torquing they are stressed past yield (intentionally deformed/elongated). | ||

Court |

>>>>During full torquing they are stressed past yield I've experienced the same thing....I mean ME; not the frickin' bolts. | ||

Blake |

Me too. I've been permanently deformed. Unfortunately I have no viable alternative other than to keep using me. | ||

Rocketman |

Even following the sage advice the bastards (sorry for swearing but they'll do that to a person in the end, lol) will snap off if they so feel like it. My experience tells me, no two Buells are the same in this respect. Your bolts might never snap. Mine are onto their fourth headache! Not my head, the Buells  Rocket | ||

Blake |

Sean, Have you made sure that the tapped hole is well deep enough so that the bolt is not bottoming out as it is tightened. I've heard a rumor that such a condition may be responsible for some failures of the bolts. | ||

Bobpaul |

My main question was whether I should just leave the bracket assembled to the head. Seems like good insurance to go to the extra trouble of tearing it all apart and replacing them, given the damage if (when) they break. If I do take it apart then for sure I'd get new bolts. Which, BTW, are listed in the parts book as "grade 12". I think they are equivalent of "grade 9", aren't they? Just L6 brand bolts? What the best way to heat them to soften the loktite? Propane torch on the head of the bolts? Heat gun on the cylinder head where the bolts screw into them, maybe? I've got the 99/00 service manual and they say clean out the holes with a tap, apply new loktite red and torque to 73-78 ft-lb. I don't have a copy of the service bulletin, but I remember reading someplace to torque the bolts to 30 ft-lb to seat them, loosen and then retorque to the spec. thanks! | ||

Blake |

Sounds like you are on the right track to me.  | ||

Rocketman |

Have you made sure that the tapped hole is well deep enough so that the bolt is not bottoming out as it is tightened. I've heard a rumor that such a condition may be responsible for some failures of the bolts. Well Blake, I always said that the stock bolt fitted from new was about a centimeter too short and didn't bottom out in the hole, and that's why the head snaps on the right bolt hole. If you look at the head the right side hole is bored into an area that has a slight nose to it. Where that nose extends into the larger area of the head casting is where it always snaps. That is exactly the depth where the bolt stops. To make good my broken Dick O'Brian flowed head that weak area was welded over and over and over, and dressed then painted again. It is still intact and the paint is not showing any signs of fatigue. Another concern of mine was the depth of the holes in the head. They offer more depth than the bolt is long, so I cleaned them out and ran a blind tap down them and they are good. The next problem is according to my local nut and bolt stockist (ancient established company of great standing) no one makes a bolt with the correct strength, right shank length and thread depth that fits the measurements our Buells require. The solution was simple. I found such a bolt with the correct strength that fitted the thread depth perfect but it had a deeper shank length. I had some billet washers made up of about 5mm thickness to take up the extra shank length and the bolts went in great, with locktite. Now the left one has broken again, for the third time, I can't get it out. Maybe this week after finally finishing of a very busy work load, I might get time to try and get it out. I have borrowed a stick welder and will possibly try the methods we mentioned earlier in the other thread. Wish me luck. Oh yeah, when and if I do get the broken threaded piece out, I'm going to be looking for a higher strength bolt (and a new billet washer, lol). Rocket | ||

Bomber |

not sure if propane will produce enough heat to allow you to brake the loctite loose -- the entire assembly is a pretty big heat sink, and propane/mapp may not be up to the task -- your call, but if you've not had trouble, I wouldn't go looking for any (I'd leave the bolts in) in any event, keep us up to date on your project, please -- we LOVE to hear the war stories (hopefully good ones)! | ||

Rocketman |

Tried the glowing red hot welding rod trick on the broken stud. Not a chance. The problem is, holding the rod on just makes the rod get hot first, until it gets so hot it just wants to go limp then melt away. After such efforts the stud is still able to be touched it's barely luke warm. Tomoz, if time permits, I'm covering up surrounding items to protect from welding splatter and Ill try welding a blob on top of the stud and go from there. Rocket | ||

Bobpaul |

Rocketman, In my previous life, doing machine design, we would have the offending character EDM'd out of there. Depends on the cost of the machining vs the value of the flowed head. Ya just gotta think there is something wrong with the design if 180 ksi bolts keep breaking. If one looks at the head from the side, both bolts are in line with each other and that means there is not much strength to resist bending moment. Seems like a "strap" going from near the top of the mount over to the mounting bolt for the choke bracket might add lots of stiffness. Also, great idea making up the spacer and using the longer bolt. So, how do you get them out? A giant breaker bar? Seems like heat would help soften the loktite... but how to apply? thanks everyone! | ||

Rocketman |

One way or another, I'll get the sucker out. I'm adamant I'm not going to involve removing the head. I sojourn next week for about a fortnight. When I return there's a month or so of riding season available before the weather turns inclement and I have to fight with dark nights. Because of this busy work schedule I've tolerated recently, I at least want to ride this Buell sucker several times before nature makes that a next year activity. Hence I'm looking now for the quick repair. Rocket | ||

Jackbequick |

Heat will destroy Loctite's grip, it will not return after cooling. It takes 700F (371C) to do it I've read. Sean, on the droopy welding rod, try a larger welding rod or even a stub of metal. The point of that is to get a high resistance connection at the contact point so that the heat builds. And I suppose if you can have a positive electrode so the current flows from the bolt to the electrode, that would be better. You want the electrons are ganged up in the bolt, running around in circles, and getting overheated as they wait to disembark. Much like a returning troopship. Another way is to drill a hole down into the bolt and then strike an arc and weld from the bottom of the hole upwards. That give both heat and expansion and after it cools it will be relaxed. If there is any protrusion on the broken bolt, maybe you can weld a nut to the end of the bolt and then use that to turn it. Jack | ||

Rocketman |

Well Jack, I only had use of a 100 amp stick welder and thought it might cut out or blow a fuse. I thought about the rod down the middle of the stud, and that might be my next option as the weapon of choice could end up a failure.  Rocket | ||

Rocketman |

So I centre popped the broken stud with a spring loaded punch then set about it with drills 5/64th 3/32nd 7/64th 1/8th 9/64th 5/32nd 11/64th and finally the recommended 3/16th to get the stud remover in.  Got myself pretty much central. Not bad considering I'd butchered the stud with a punch and some heavy hammer blows to start with. Obviously I dressed the broken stud face first to get a good chance of middle wicket with the drill, lol.  Rocket | ||

Rocketman |

Then I knocked in the stud remover and applied the gas torch twice and put in some considerable heat.  And guess what, it's still in there! That sucker is in there tighter than tight. I had a deep six point 13mm Snap-On socket and a 3/8th long ratchet handle on that stud remover, and I tell ya I could have thrown a rope around that handle and climbed a twelve storey building with it and it wouldn't have moved. What's next? Monday is what. I'm staying away for the weekend, lol. Rocket | ||

Sarodude |

Hey, Sean, it's good to see someone have a good sense of humor about this stuff. Recently most of my wrenching has been frought with ridiculae. It's nice to not get too wrapped up in the negativity. -Saro | ||

Rocketman |

Well Saro, sometimes it's hard to have a sense of humour, and the Buell is real good at trying ones patience. Well I arrived at work late into the day as usual. I never rush. Especially on a Monday, lol. Fresh from a weekend away from the workshop, and with clean and pure thoughts about how to get this stud out. I decided a few days ago that heat was the only option, but trying to hot up the surrounding head area was proving to be a waste of time. Well it doesn't take a genius to work out it's worth trying to get the stud red hot instead, at least at the end one can see, so that's what my weekend of thinking lead me to. So heat it up I did. Once cooled off and the easy out in place it becomes one of those shit or bust sort of deals where the risk is of breaking off the easy out tip into the drilled stud, then you've really got your work cut out buster!  Anyway, I needn't have feared as the heat seemed to do the trick and break the seal of the locktite. It's always a question of experience at the end of the day. You simply have to know how best to apply force to the tools you're using. Much to harsh and bull like will see you disappointed for certain, so I applied as much pressure as I dare, all the time using that ever so slight touchy feely thing mechanics learn over the years from zillions of failed attempts at similar efforts, just waiting for a sign from within that says 'hey that sucker moved I'm sure'. So you ease off and have a closer look in disbelief, and you could swear the thing turned at least a cats •••• hair, so you go again this time praying it wasn't the easy out snapping, and it wasn't. Rocket | ||

Rocketman |

Well it started to shift, slowly but surely, and that put a big grin on my face I can tell ya.  Rocket | ||

Rocketman |

So I dared to keep on turning, and it just get better and better.  Rocket | ||

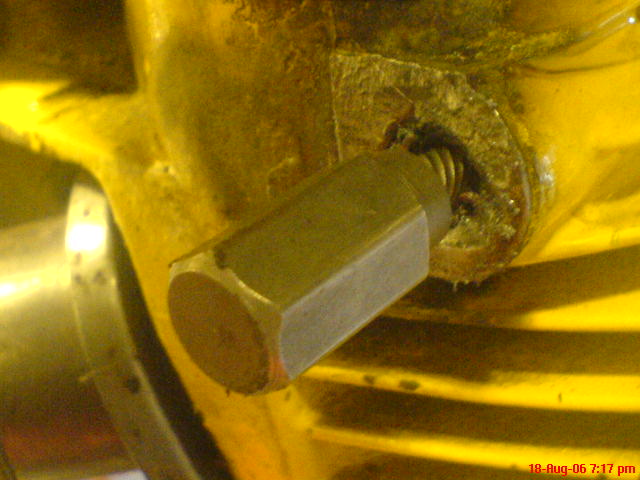

Rocketman |

Perseverance Ltd paid off in the end, save a little scorched paint that I'll be touching up tomoz, and the misery is almost over.  Note the serious amount of locktite? What was I thinking last year. That this bolt would never snap again. How mad could I have been thinking it would never have to come out, at least not broken. Anyways. I look in the manual and I can't for the life of me find the torque settings for these damn bolts, and now I'm wondering what torque I used last year, and where I got the specs from. Can anyone help? Rocket | ||

Bomber |

Rock YAY! stubborness and bloodymindedness carry the day! can't help with the specs, but I know they are around here somewhere's and have faith that some bright spark will speak up! | ||

Blake |

73-78 LB*FT according to my service manual torque specs. | ||

Jackbequick |

Yayyyyy!!!! Award yourself an extra pint at the local! Jack | ||

Rocketman |

Thanks for your support gents. And Blake, if they're wrong you best ring me sharpish before I bust another one, lol. Thanks again. It's been memorable (ass usual). Rocket | ||

Henrik |

Good going there Rocket. Snapping that "easy"-out would have royally sucked ...  Henrik |