| Author | Message | ||

Deanh8 |

Does anyone have any info on the differences in the internals of the RS vs the RX? Im told the RS has a lighter forged rotating assembly and has longer rods and different pistons. Can anyone confirm this or know any more info? | ||

Snacktoast |

I can confirm that the crank, rods, and pistons are not the same between these two engines. The RS uses I believe Carillo rods and CP pistons. The RX has Zuhl rods and Mahle pistons. I don't know the exact details on the crankshaft. | ||

Zac4mac |

RS has a bunch of differences from the RX. As Snack says, Carillo rods, CP pistons in RS. RX has different heads, RS are 1125 era heads. RS has Suter slipper RX does not. RS has Ti valves, pretty sure RX does not. Have heard RS has different cams, not sure of that tho. Surely there's more, RS' were all hand built. My RS rides more like a Firebolt with too much power than its predecessor the 1125. Z | ||

Snacktoast |

Yes, Zac. The cams are different. | ||

Coolice |

The ET-V2 is hand built too! | ||

Davegess |

That pretty much sums it all up. | ||

Ace117 |

The RX also has Ti valves as well. I asked one of the EBR techs during the Launch party last year who made said valves, I was told DelWest. | ||

Stevel |

Please also note that the CP pistons of the RS are cut from solid AL 2618 billets and the Mahle pistons of the RX are forgings and probably AL 4033. The cranks on all these motors are the same 4140 forgings, of course with different balancing. Please see my post on the 1125 forum about the cylinders. They are the same original 1125 casting, but with different bore sizes. | ||

Zac4mac |

Got back from Homecoming and now I know what the inside of the heads looks like. I brought home 2 - 2009 1125 crate motors, 2 sets of RX heads, 1.5 sets of RX Del West Ti valves and a cam set. There is a little room for flow improvement. Speaking of Ti, I found 2 trays of very big 5/16 stem valves in Ti. Turns out they are XBRR valves! Z | ||

Stevel |

"There is a little room for flow improvement. " That's a very bold statement. Since the castings haven't changed since the 1125, I think that statement is pretty much indefensible. Since you now have RX heads, I would really like to see photos and measurements. It would really help. | ||

Crusty |

You do know that Zac makes his living porting heads, right? Having watched him working and hearing the reasons why he does what he does; when he says there's a little room for improvement, I believe him. | ||

Stevel |

The problem with these heads cannot be improved with the removal of material, which is the normal methodology of head porting. In this respect, Zac would be correct, but there are other factors that greatly effect engine performance, like gas velocity and these heads have ports that are referred to as "lazy". In other words, the ports are too large, gas velocity is too low and they have the wrong shape. Great improvements can be made, but those improvements can only be made by adding material reducing port volume and changing the port shape to encourage a greater venturi effect. This would in turn increase combustion chamber turbulence increasing flame propagation speed and overall combustion efficiency. Perhaps Zac means that he cannot improve the flow in these heads. In which case, I believe him. That does not mean these heads do not need serious help.....they do. However, a casting change is in order or internal port welding. In either case think cost. | ||

Hughlysses |

If the problem is intake ports, why couldn't something like JB Weld (epoxy) be used to add material. The famous race mechanic Smokey Yunich used lacquer to smooth out the intake passages on Hudson Hornets to get around a NASCAR rule which prohibited "porting" of engines which was defined as removing material to improve gas flow. | ||

Ducbsa |

I googlized "epoxy in cylinder head" and found various forums discussing the topic and this product http://www.jegs.com/p/Moroso/Moroso-A-B-Epoxy/7476 61/10002/-1 | ||

Stevel |

This stuff has been around for awhile. In point of fact EBR were doing heads this way in 2010. Michael Richter tried to sell me a set of "ported" heads prepared this way for a very substantial price.........I declined. Not because the heads were not done well, but because of the epoxy. I cannot bring myself to gamble the total destruction of an expensively prepared engine betting on the adhesion of a lump of $2 plastic. I met Smokey at his place in Atlanta in "76 and I can't imagine him doing it either. Just sayin! | ||

Ourdee |

And how does texturing the passage figure in? | ||

Zac4mac |

Steve - No magic. just port matching. My RS has been sanded for a smooth tract from mouth to valve. 1125R not so. There are also some sharp edges I would round... I now have some parts to play with. 2 - 2009 crate motors, 2 sets F&R heads, 1.5 F&R valve train/cams I agree with Steve, epoxy belongs Outside a motor. I know a very good welder. The texturing I do in intakes is to establish a small boundary layer of turbulence along the walls to boost flow. Like dimples on a golf ball or fuzz on a tennis ball. | ||

Stevel |

Zac, I would really appreciate photos of the RX heads and measurements to validate that the RX head castings are essentially the same as 1125 heads. Specific dimensions like port volume, valve sizes and the distance between the machined spring seat floor (both In & Ex) and the deck surface. I would normally do this with a height gage, if you have one. Combustion chamber volume differences would also be a good telltale. Also, please note any other differences your eye detects. Thanks in advance, | ||

Zac4mac |

Will do Steve. Gotta get caught up with my H-D lump heads first. Off to do that now. Z | ||

Zac4mac |

Steve - I think I got one of the heads you referenced. I'll post pix tomorrow. Putty in the throats. The one head I got with valves and springs, no locks. Same exhaust valves as stock, different intakes. | ||

Ourdee |

I want to see. | ||

Zac4mac |

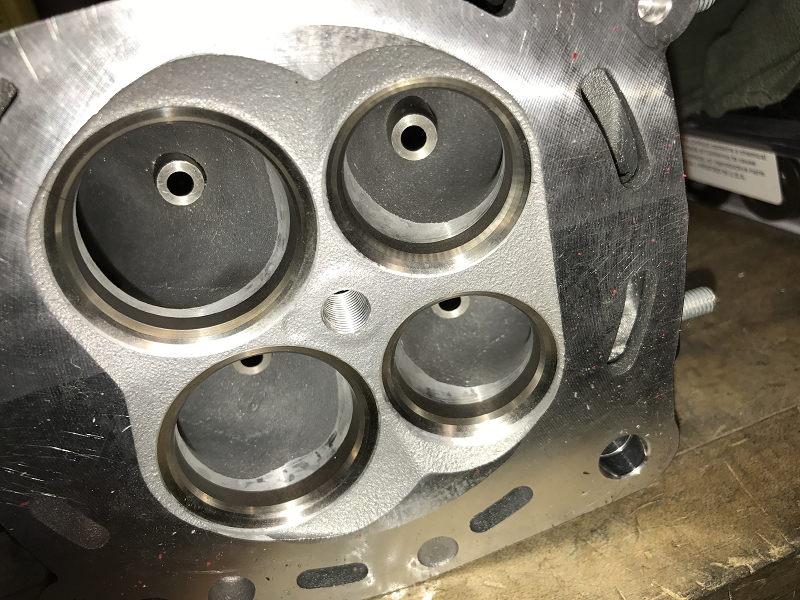

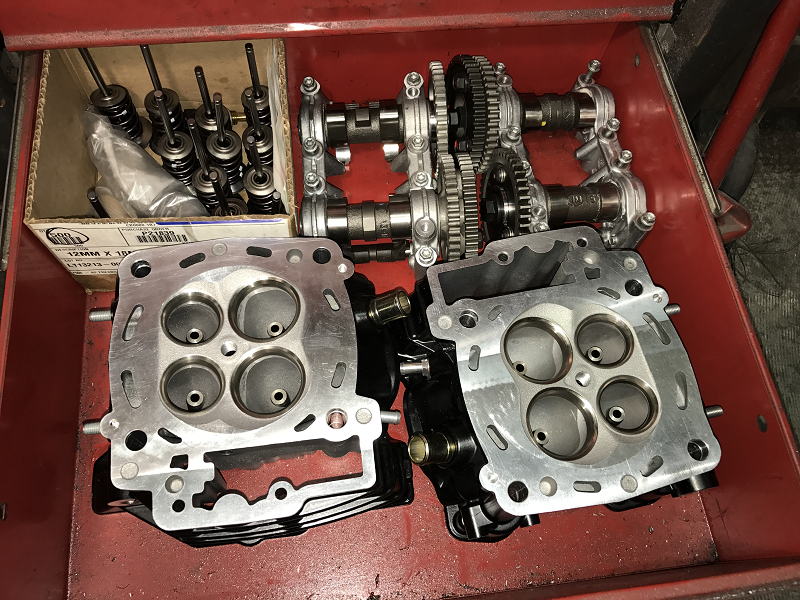

Pretty busy after getting back from E. Troy and spaced the pix Mon, Tue and today. Went back and got pix..... Stock head  Intake  Massaged head  Intake  Exhaust  RX Head kit  Z | ||

Stevel |

Thanks Zac. I do not see any difference between 1125 and these RX heads from the photos, but you have them in front of you, so your personal observations here are important. Do you have access to a flow bench? Two observations on the modified head I see. The first being the epoxy on the floor. This is right idea, but the wrong solution. The second is the shortened valve guides in the port. This is a really bad idea, especially with these heads. I understand the perceived value in gas flow, but, in my experience, this is marginal at best. One of the issues with these heads is lack of valve spring space and limited valve travel to accommodate higher valve lift cams. The available space will only accommodate 10.5mm of valve travel without interference. increasing valve travel must include deeper spring pockets and shortened valve guides. Further shortening of the guides within the port will drastically decrease the guide's ability to stabilize the valve stem and increase guide wear substantially......very dangerous. My valve lift target is 14mm which is hugely problematic with the limited material at the spring floor, hence my request of the spring floor height measurement. | ||

Ducbsa |

It is surprising that those issues exist in what was IIRC a fairly clean-sheet design of the 1125 by a talented passionate team who had to know about higher cam lift. Cycle magazine was featuring filling in the intake tract floor of an SR500 in the '70's. Don't take me wrong, I'm not Monday morning QB'ing here; I just think there must be a story from 10 years ago that would shed some light on the issue. | ||

Zac4mac |

As far as 1125 - 1190 differences, all 4 heads have EBR in the casting. They also have a hole drilled into the side of the intake tract which I'm pretty sure is for the "fresh air induction" for intake swirling. Yes, I have a Superflow 260 flow bench and will be using it when I start assembling/modifying the RX heads. Any idea of rough numbers to look for to have sufficient flow at 11k rpm? Pretty sure I want a flow "pinch" just before the valves to raise the velocity into the combustion chamber. <edit> Have you ever seen guides with a teardrop cross-section? Seems that could make them almost invisible to flow... (Message edited by zac4mac on June 23, 2017) | ||

Stevel |

Zac, You are correct about making the guide extensions more aerodynamic.....it works and is a good compromise that doesn't risk stem stability or guide wear. On the subject of design logic referred to by Ducbsa, I see American drag race influence through out the engine design from combustion chamber, port shape to cam timing and it isn't applicable for motorcycle engines unless you only drag race. Consider for a moment the amount of time the engine is at full throttle and maximum rpm on a road course. It might be 10% of the lap. The rest of the lap the engine is running somewhere between mid speed and 80% of engine max. and under partial throttle. So why in hell would an engine designer tune the engine for the highest engine speed and WOT? It just doesn't make sense. The correct tune must be for the range of maximum use. Anything less is stupid and yet, that appears to be what has occurred. For instance optimum gas velocity in the inlet port should be somewhere between 140 and 180 feet per second in the center of engine speed usage. That optimum gas speed occurs at an unobtainable rpm with these heads. The cam timing of 15-60, 60-15 also reflects the same thinking. With the intake valve closing 60 degrees after BDC, only then can compression start. At engine speeds less than ideal gas velocity, gas reversion becomes the order of day greatly disturbing laminar port flow. Consider why, with the standard compression ratio of 12.4 to 1, you have no detonation issues using 87 octane fuel. The answer is the dynamic CR is only 8.5 to 1 because of the late intake valve closing event. I can go on, there is much more that can be said about this subject. I haven't even mentioned the incredible increase in valve train load by trying to open the exhaust valve at 60 degrees before BDC. At that time, there would be very significant cylinder pressure still in the cylinder. In conclusion, the entire engine design is centered around an unobtainable engine speed sacrificing mid range power and efficiency. This is also the reason the engine runs like shit below 4,000 rpm. Interestingly, the total intake length is spot on correct. I calculated the tract length to be optimized at 8500 rpm. Most likely Rotax was responsible for that. The Japanese and Europeans know better and that is the primary reason EBR had their ass handed to them in WSB competition. | ||

Snacktoast |

Geez Stevel, surprised you didn't volunteer your services to EBR...ya know, considering everything they did was junk.  | ||

Zac4mac |

Snack - you and I know a bit of what it takes to get Erik's ear and keep it. I wouldn't be surprised if if Steve did offer some advice... I believe him when he says he's a retired engine designer. I'd love to hear more of his background. I will say, Betty(my carbon beauty) hits peak torque at around 10.5-10.6k rpm. At least, on the dyno. Another thing I'll say is, Loretta isn't fond of anything but premium. The RS is a bit pickier yet, the difference between 91 with or without ethanol is noticeable. When I go to the sprints, I bump the advance up 8-10% at the top-end, and run Sunoco 98 No-Alcohol. That seems to get me another 4 or 5 mph. Z | ||

Snacktoast |

Zac, I mean no disrespect to you and other engine builders out there that are squeezing performance out of the proverbial sour lemon. I truly have respect for that and it's a shared passion. But I get annoyed when a few out there play the Monday morning quarterback and believe that their way is the only way, meanwhile having no knowledge of the inner workings of why things were done a certain way. Has Stevel bashed the crap out of the 1199 Panigale engine? Beacuse, ya know, up to 10000 rpms the EBR 1190RX out runs it and has a flatter torque curve. Clearly the Italians don't have a clue either.    99% of the people bashing the 1190RX powertrain have never thrown a leg over it, and most that hate it do so just because it's a twin and not from Japan. | ||

Stevel |

Zac, Your fuel observations are correct, but keep in mind that the RS pistons are different. I believe they have a static CR over 13.x to 1. Having not checked the RS CR personally, I can't say for sure, but reliable sources have stated that both the pistons and the cams are different. I suspect the RS cams are the same cams that EBR used for their early 1190 racing engines in Europe and if so, they have a 1mm higher lift than stock 1125s. Snack, Yes, I am playing the Monday morning quarterback, but the numbers don't lie. You are welcome to make your own measurements and calculations as I have done if you think I'm incorrect. You are also correct that I do not know why or how the design decisions were made during the design phase of the Helicon, but I would love to know the real story too. In point of fact bad design decisions are almost never made by the professional design folks. These decisions are normally made for political, marketing and financial reasons by management. I do not consider my observations of the Helicon bashing. It is simply stating the facts as I found them. I don't "bash" the Panigale, because it is not relevant on a Buell forum. However, since you mentioned it, the Panigale performs exactly as it was designed. It is designed to run at speeds much higher than the Helicon. It uses a much shorter stroke with a huge bore size allowing engine speeds far in excess of the 11k of the Helicon. Please do your own piston speed calculations. This max speed difference allows the Panigale to achieve correct port gas velocity without self destruction. The Panigale design sacrifices low to mid range torque for high speed horse power and it performs accordingly, just as you have stated. What is to be criticized? The Helicon, on the other hand does not possess the bore/stroke ratio or the valve train for the engine speed to take advantage of either the cylinder head ports or the chosen cam timing.......it is just wrong and a clear mistake. I have also owned, driven and hot rodded many 4 cylinder motorcycles. I personally prefer the natural characteristics of twins over the fours for their broad power band and overall drivability, but that doesn't make me ignorant of other engine designs. I can remember like it was yesterday when I was sitting across Pops Yoshimura's kitchen table just outside of Tokyo in 1972 with my Z1 head in front of us long before Pops came to California and got into Susukis. I try very hard to express only facts that I have personally discovered and observed over my 58 years of experience of hot rodding and engine design. If you wish to dispute anything I state, I welcome it, but please do so with your personal observations, not BS you read in some magazine. If you do not have those observations and you wish to ask questions, that is also fine. I would be very happy to pass on my knowledge and have those discussions. | ||

Hughlysses |

This is also the reason the engine runs like shit below 4,000 rpm. Interestingly, the total intake length is spot on correct. I calculated the tract length to be optimized at 8500 rpm. Most likely Rotax was responsible for that. The Japanese and Europeans know better and that is the primary reason EBR had their ass handed to them in WSB competition. Steve- The implication in all the coverage of EBR's efforts in WSB was they were down on top-end power, especially when they first started out. Doesn't it seem like these heads were specifically designed to maximize top end power at the expense of mid-range? After all, development of the RX was apparently funded by Hero, who wanted EBR to go WSB racing as soon as possible to provide publicity for Hero. EBR wanted to mass-produce an more-affordable version of the 1190RS. Perhaps the head design is a compromise between those two somewhat conflicting goals. Your comments on the faults in the design seem reasonable and mostly obvious. It's a little hard to believe that this was done inadvertently considering there were a lot of very smart engineers at EBR. I worked as a mechanical engineer for over 30 years. I occasionally ran across things in designs that seemed to be bluntly wrong. At least some of the time, when I questioned these apparent flaws the designer would provide a non-obvious explanation for the design which showed it was correct, at least within the constraints the designer was working under. I have no doubt the 1190 heads could be improved, especially for street use. I am not convinced this was an oversight/error by the engineering team that designed them. | ||

Stevel |

Hugh, I can't answer for other's motives for doing what was done or not done. I simply don't know, but I also doubt the design decisions were made by the design engineer. Never-the-less, these were the decisions made and I'm sure there is an interesting story to be told. I only know what my observations and experience tell me. On the power question, power in equal to the fuel consumed correctly, over time. It isn't rocket science. In EBR's case, the tune was for an engine speed that was mechanically unobtainable without self destruction. As far as engine development for racing.....there was none. I suspect not because of the lack of knowledge, but because of cost. The money simply was not there to do the things necessary either by EBR or HERO. Good designs rarely just pop off the drawing board, they evolve through failure and lessons learned in an evolutionary process, iteration after iteration.. There were no design iterations, just applied band aids. Erik's WSB results were entirely predictable. Erik's ambitions were significantly larger than his pocketbook. Zac's assumption is also correct that I did have several conversations with EBR through Michael Richter. My impressions after those interchanges were that the design group, as smart and knowledgeable as was advertised, suffered from the "Not invented here syndrome" and I'm not alone with that impression. (Message edited by steve-l on June 24, 2017) | ||

Ducbsa |

Regarding self-destruction, wasn't Ducati replacing crankcases after every race for a while? From an earlier era, I remember Reno Leoni complaining that his beefed up NCR cases were protested even though they were heavier than stock items. Maybe he should have gotten NCR to use the remelt XBRR approach? | ||

Oddball |

Zac, instead of a teardrop perhaps a p51 wing shape would be a more efficient guide shape? | ||

Zac4mac |

When I'm doing the exhaust, I make the guide boss an asymmetrical teardrop, almost an airfoil shape. No reason there other than to "mark my work". I do a reverse airfoil with the floor of the intakes, which I believe, helps promote a swirl into the chamber(along with other subtle changes). I like the intake port of the early twin-cam with the exhaust of the late one. Back to the guide boss and guide, I would probably stick with that asymmetry. I like the idea of having one side of the port, relative to the stem, carry more flow. It's easier to make the valve "flow invisible" by putting it to the side of the flow than dealing with it in the middle. Especially in the intake. Z | ||

Interested_engineer |

steve zac4mac according to my recollection the 1190rs has valve angles around 7 degrees. i am curious why ebr departed from the standard angle of about 12 degrees used by pretty much all superbike heads. it is clear the very narrow angle shrouds the valves less in the head and simplifies getting a higher compression ratio. however, i have read of experimental studies that indicate 12 degrees is about optimum, i think because of improved charge tumble. any comments or technical references from anyone? thanks | ||

Interested_engineer |

steve is the cam timing you quote of 15-60, 60-15 seat-to-seat numbers? does anyone have actual valve lift vs cam angle measured data they can provide? i read of the 1190sx opening one intake valve earlier than the other to promote charge swirl. any comments or data on that? thanks | ||

Stevel |

John, Those cam numbers are hard to measure. I made a fixture that measured net valve travel with a dial indicator and a degree wheel mounted to a drive gear. The head and fixture were mounted on a bench. I then recorded valve displacement every 5 degrees of cam rotation and recorded the measurements in a spreadsheet. My quoted numbers start and end at 1mm off the base circle. This allowed me to plot the valve acceleration relative to the angular displacement of the cam as well as total valve lift and the opening and closing points of the valve for both intake and exhaust. I did this with the stock 1125 cams and a set of the early 1190 racing cams. My method also considered the motion multiplication of a properly shimmed finger follower. I did this multiple times to assure myself I could repeat these numbers. Greater fidelity could only be done with a CMM and dividing head, which I do not own. I'm confident my numbers are close. I can provide the spread sheets, if you want. Interestingly, the valve acceleration/ deceleration (thousands on an inch/ per degree of cam rotation) are almost the same for both the stock and racing cams. As a follow on note, I did this when the intake and exhaust drive gears were on the factory timing marks. Since these timing marks represents start TDC of the 720 degree engine cycle, factory valve overlap can also be clearly seen. | ||

Interested_engineer |

hi steve this is exactly the data in spreadsheet form that i want. if you happened to take any data all the way down to the seat and you could throw that in it would be useful too. i am not an experienced blogger but and i believe see a place i can send you a direct message containing my email address. if you do not get a message let me know. thanks so much | ||

Stevel |

John, I did receive your request and have forwarded my spreadsheets. I hope you find them self explanatory. You should be able to use graphing software to plot the data points and smooth them at the same time. If you do, please send the graph to me. I need to make new cams to my design, but after speaking to many camshaft makers, I have become very disenchanted with their service and costs. I am looking for a cam grinder to make my own. As another note I have much more data and custom made parts. | ||

Stevel |

John, You have mentioned the valve included angle in different head designs. Yes, the more narrow angle has performance advantages, but those are offset by physical space considerations for valve train gear more than anything else. Narrow included angles also have disadvantages, as they eliminate the use of an effective squish area, which directly affects flame propagation time especially under reduced throttle. This affects efficiency. Some of these effects can be compensated by piston design (Piston head profile), but engine design is all about compromise. The most effective and efficient combustion chamber shape is the hemispherical chamber, but they require a large included valve angle, a two valve design and a domed piston for a good CR, which causes loss of volumetric efficiency because of impeded gas flow during valve overlap. The more modern flat pent roof shape aids volumetric efficiency, but at the sacrifice of a squish chamber and a longer distance for flame travel.......take your pick, you can't have both. If you choose a pent roof chamber as Rotax did, you have to compensate for the long flame travel distance, by increasing intake turbulence though higher intake gas velocity and turbulence, which Rotax did not do. This is the primary reason pent roof designs are very sensitive to port shape, valve size, valve shape and piston design. | ||

Skntpig |

Zac, I'm surprised you didn't weld up the port floor of the exhaust a bit like a small D port. Looks like high velocity intakes. I did this trick on my S1 with amazing results. Let me guess...You break in your bikes with full throttle too...(Mxxxman?) Keep in mind I'm just looking at pics and not an engineer by any stretch but looking to learn if I can. Cool stuff. Thanks for the pics. (Message edited by skntpig on January 04, 2018) | ||

Mcuchy29 |

Is there enough clearance and wall thickness to increase the bore size on the ebr1190rx/sx and if there is by how much. Cheers | ||

Stevel |

Mark, The cylinder casting is the same for the 1125 and the 1190. The original bore was 103mm for the 1125 and now the 106mm for the 1190. The casting uses an open deck design and the only bore support is at the bottom less the 4 water ports and along the chain case along that side to the top. The bore OD at the deck is 118mm and at the bottom 112.5mm where it enters the engine case. The thickness of the wall between the bore surface and the inside of the chain case is 9.58mm using a 103mm bore size. I guess you can do your own arithmetic. Keep in mind that the engine structure is an integral part of the chassis and I have seen signs of dynamic bore shift where the intake valve has nicked the side of the valve relief in the piston where at rest there has been more than 1mm of clearance at rest (clay test). The bore is not stable even at 103mm, let alone at 106mm and with its asymmetric support, I can only imagine how well the bore maintains its roundness under heat and load. Adding to that, consider the EBR experience in WSB where they were blowing out head gaskets regularly should pretty much answer your question. | ||

Mcuchy29 |

Thank you for the information Steve. | ||

Mcuchy29 |

Hi Steve after being on the ebr Facebook forum, Iím thinking of getting LA sleeve to insert MOLY2000 centrifugally spun-cast ductile iron cylinder sleeve liners. for strength and longevity for the standard bore size. This makes me ask in your opinion with that modification would it be possible to go slightly larger on the bore( just curious) Cheers, Mark, | ||

Stevel |

Mark, Sorry for not answering earlier, but I was just released from the hospital after suffering a heart attack. I can tell you, getting old is not for pussies! On your question. I love LA sleeve products. I have used then successfully for many years. I have asked myself the same question. My biggest concern is the cylinder casting itself and the amount of material you have available. Consider also that this is a wet engine and it has an open deck on the cylinder. I think that mod would be dubious at best, but a trip over to LA Sleeve would be worth your while. Ask them, they know what they're doing. | ||

Mcuchy29 |

Wow, glad you made it through. Hope youíre on the mend. Sounds like i should drop that line of thought. Iím in Australia which is why I like listening to people like yourself. There are several people looking into this sleeviing on the EBR Facebook forum. Hopefully a few people go this way to make it easier for me considering the difficulty I would have communicating outcome from a distance. | ||

Mnscrounger |

Stevel; Glad to hear your still with us.Best wishes for a speedy recovery. Most of what you (and others) post in this forum is above my full understanding, but it's still a good read. | ||

Ace117 |

Trying to spread the word Myself and George Dan over on FB (hes also on EBR forum as gdisaac07 http://ebrforum.com/member.php?1288-gdisaac07) we have been in the works with L.A. Sleeve working a deal to start getting cylinders sleeved for our bikes. I have 40 cylinders along with new connecting rods and pistons which I am selling as complete kits. We have got the ball rolling but need to send in all the cylinders in order to get it done, there is a kick start up ( https://www.indiegogo.com/projects/ebr-1190rx-sx-c ylinder-sleeving-kit#/backers ) to fund the project. My FB is below. Check out the FB post for more info. I have been in contact with George Dan about sending all the cylinders to L.A. Sleeves to get sleeved. George got word back from L.A. Sleeve and we are a go to have the cylinders done. From the looks of it EBR was already in the works with them but it fell apart once they shut down. The sleeves will basically be the OEM fix EBR had in the works. I will be be sending off the cylinders and shipping everything as a kit those who partake. This is a great opportunity to reestablish relationship ruined by the EBR receivership. From George Dan: I talked with Dave. He is 100% leaning towards going with the spun-cast ductile. He says it's extremely strong, and he'd be comfortable with thicknesses as small as 1.50mm wall thickness. For reference, the stock aluminum sleeves in the 1190 are 3.48mm, and the 1125 has 4.5. By that, he thinks we could get 1340cc out of the motor with just boring and sleeves. That being said, we're going to stick with the stock 3.48mm sleeves and make them out of spun-cast ductile iron. This will make them bomb proof. It means we can run the engine at full attack on a race track without worrying about the engine blowing up. This is an OEM design essentially. The only downside to going with ductile over aluminum is that the cylinders will run slightly hotter. Aluminum is a better heat conductor than ductile iron. But the stock cooling system is sized for it. Cylinder set pricing: $900 for complete set of 2 stock cylinders, 2 rods, 2 pistons, and wrist pins/circlips $1500 for complete set of 2 upgraded cylinders, 2 rods, 2 pistons, and wrist pins/circlips. I will need 10 paid pre-orders in order to be able to do the sleeving. The reason for 10 is because I only have 10 complete sets. I will have 1 new cylinder and 1 new piston left over, 9 used cylinders, 8 rod sets, 1 lonely Rod and 4 new 1125 cylinders. The sets will be race-ready and the cylinder cracking issues will be 100% a thing of the past. | ||

Stevel |

I know this is an old thread, but I am curious how these sleeves have worked out. I have serious doubts they can be successful. In my mind the sleeve would have to be a top hat design that closes up the open deck. This lip would have to have milled water ports to correspond with the head gasket and head casting. My concern is not strength per say, but cylinder distortion under chassis load. I doubt the cylinder will remain round. | ||

Xbpete |

Steve. the cylinders just now, I mean literally within the last week started showing up. Long story ... so no installed results or anybody putting them on that received them that I have heard,,, would be pretty big news, lotta folks have been waiting,,, Pete | ||

Stevel |

Pete, Please consider changing the design of the sleeve to incorporate a top hat as I described before. The aluminum cylinder would have to be mounted on a rotary table and the open deck would have to be machined to accept the top hat lip with an end mill. This lip would have to extend from one side of the chain case to the other. It would not be 360 degrees. I think that mod is very important because it would keep the cylinder concentric under both cylinder and chassis stress. | ||

Xbpete |

Hey Steve, great analysis, I was not in on the liner purchase group, I just bought my SX but have followed the group and the bike from its inception, me being a die hard Bueller. If perchance you voyage into the quagmire on Facebook, the discussions are in the EBR 1190 Owners Group. Not the one that requires a certified VIN. I am hopeful that a fuel issue that many consider to be the cause of the detonations has been identified and a fix worked out by Jacob Stark. Some interesting discussions and solutions are coming from the group. | ||

Hughlysses |

So, Craig- Iíve seen mention of the fuel system mod on Facebook but I havenít dug into it. I take that they believe under certain circumstances the evaporative recovery system can dump a bunch of raw fuel into the intake, hydrolocking the cylinder(s) and destroying the engine, and the mod is supposed to prevent this? | ||

Shoggin |

I don't know whats worth $95 in that "kit" but I solved that rumor/hypothesis/total guess by plugging the vacuum line to the front cylinder. No CEL. For Free.  Besides, engines can injest a staggering amount of liquid before hydro locking. I know first hand  (Message edited by shoggin on January 19, 2020) | ||

Xbpete |

Hey Hugh! Unsure if I will put Jacob's "fix" on my Sx, just carrying the message. It would be nice if we had EBR before the shutdown still in play to sort the detonating engine problems with the 1190, but, we don't. The discussions are ongoing and as the "fix" is applied and the lined cylinders are integrated into the platform the discussions and explosions that follow should be interesting. Sitting here in -1 temps and ice/snow everywhere, still have about 4 months before I roll out any of my bikes. Jacob did post this video that I found very interesting... https://drive.google.com/file/d/1kNLkenhqX9OHNuJcM 8RRd__1blCfl6yv/view |