| Author | Message | ||

Dsergison |

I swear my x1 is making more (lower end?) noise than it used to at idle. it klunks with every plug fire around 1200 rpm. It goes away by 2000 rpm. or perhaps something like an engine mount? when should you replace the rear isolators? it's hard for me to pin down where exactly it's coming from. | ||

Fullpower |

my '98 made some real unpleasant sounds before the OIL PUMP DRIVE GEAR failed. it was sort of a klunky sound. | ||

Djkaplan |

Is the primary chain tension within specs? A real loose one can make that noise. | ||

Shazam |

in order: check primary chain tension check that tensioner is in one piece check your stator nut/mainshaft nut. (makes a loud klunk if loose)* bad flywheel bearings (not likely unless you redline often) *guessing this is it | ||

Dsergison |

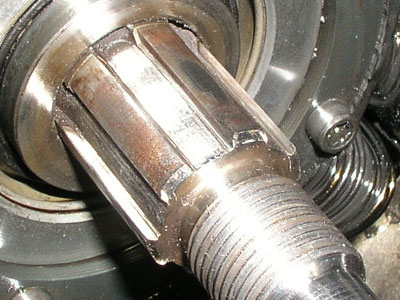

"check your stator nut/mainshaft nut. (makes a loud klunk if loose)*" Yup. it was just sitting in te end of the shaft  now lookey I think my chankshaft is TOAST  it appears the flywheel is much harder than the crankshaft. as it's splines are perfect, and the cranks look severely worn. or is that normal? I can't imagine it. but it looks weird, too perfect to me just klunked out? I'm thinking about filling the space with jbweld so it can't work back and forth and zipping it back up to see how it goes. | ||

Dsergison |

| ||

Dsergison |

I rolled some tig wire into ribbon and fitted it into the splines with locktite. I put it on the decelleration side. It removed all the slack. I Hope it works.  |