| Author | Message | ||

Conv90 |

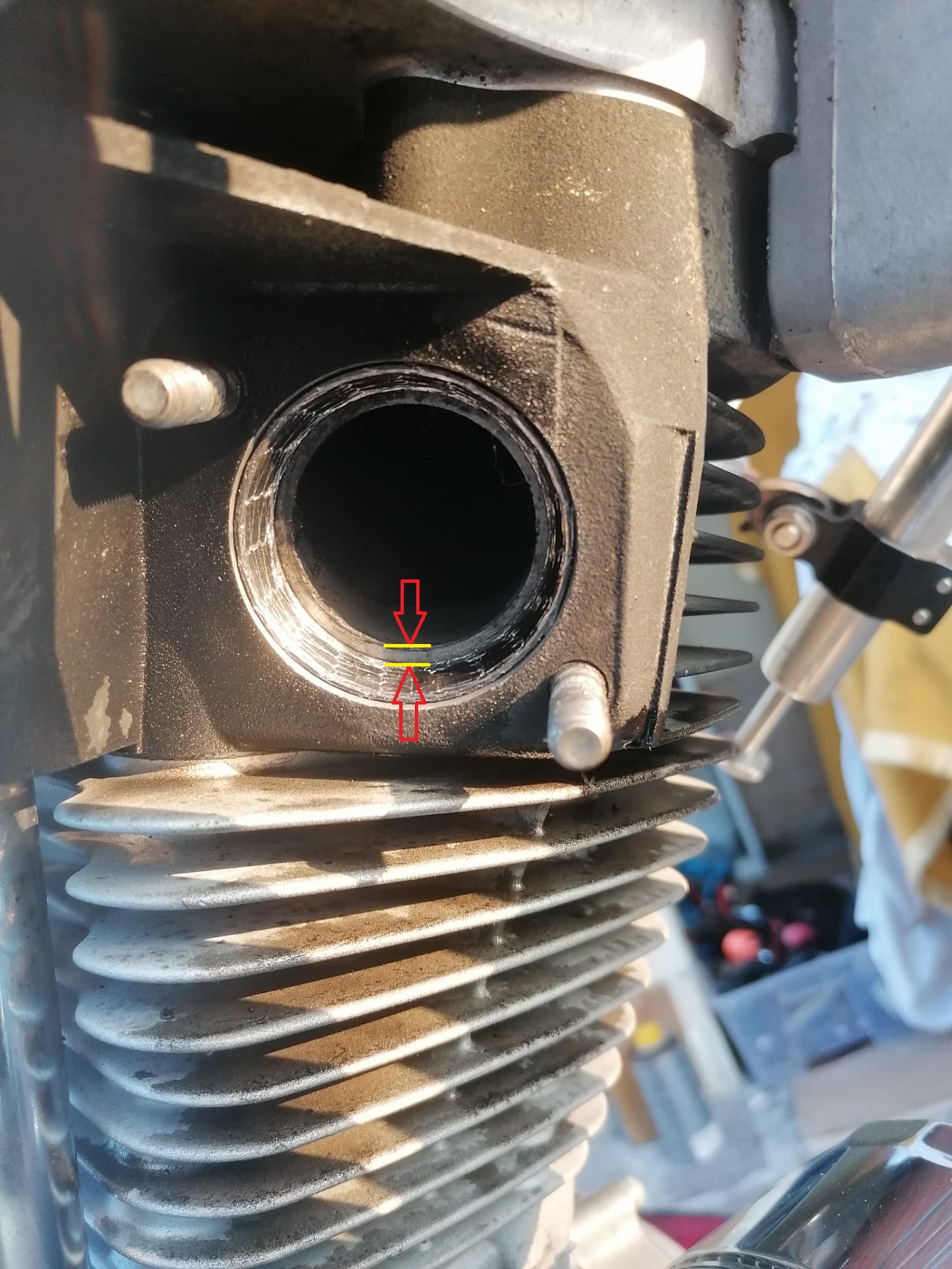

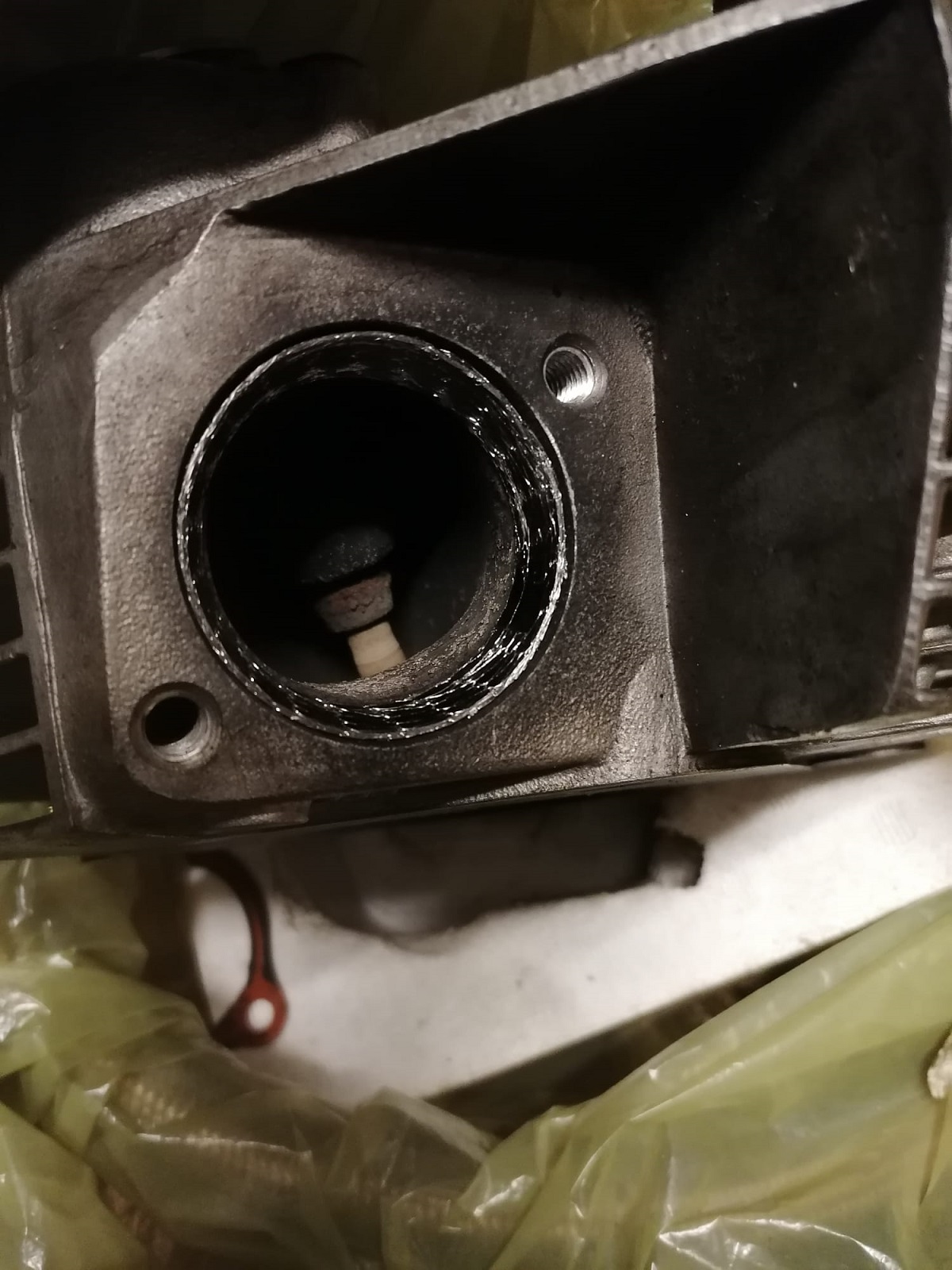

I just bought (separately) headers , mufflers clamps etc. All used parts on the net. I'm not able to seal all the parts. I have leaks everywhere. The big 2.5" exit of the headers with the muffler. They are tight fit but I still feel air escaping. So If I try to put more IN the muffler, it travels a bit forward (in the direction of the front of the bike) and the notch on the top of the muffler is no more perfect aligned with the primary drain nut, the muffler moves forward and a bit Up and I risk a contact. Now the 2 big problems: The header opening (the ones to attach to head ports) are slightly different than the original header. They have sharp edge. The original one instead has smooth, rounded edge with a good big contact surface with gaskets. This sharp edge is in contact with the round gaskets on the ports. SO when I tighten the bolts at the clamps it cut the gasket , So I need to tighten a bit more destroying it. I always used on my 90 c.i. sportster (with success) aluminum crushable gasket. With this kind of gasket I tried, but with no success because they are not perfect. They are perfect external diameter (they fit perfectly the port edge) but the internal diameter is too big so the header are in contact only for a millimeter or less. Now I tried with normal (NOT tapered) gaskets, But I have the same problem. The other problem is related , but it's another problem. Not only I have air leaks , but it sputter/sprays oil (or something similar ...it's a dense black liquid thing) It is not from the head gaskets but from the exhaust gaskets (both front and rear). It sprays also from the conjunction header to muffler. So I ask to myself ...Why I have oil coming of the exhaust? what it can be? Which kind of exhaust gasket I can use? Buellers with Race Proseries exhaust are you using differnt gaskets? And, are the edges of the pipes so sharp like mine? some pic: You can see on ZOOM how sharp are the edges.  here a puddle of oil(?) uder the rear exh port  here the muffler and 2.5" opening of header covered with oil(?).  here the front port:  | ||

Ratbuell |

1. pull the crush gaskets out of the cylinder head ports, and get new ones. They have a tapered face to the head. Install them on the header FIRST, then torque the attaching nuts on the studs.  2. the stuff you see dripping is likely just wet soot; condensation mixed with exhaust gases and rich cold-start mixture. You could have some oil in there, depending on your valve seal condition...but more than likely it's just soot mixed with condensation. Read your plugs to see if you're burning oil. 3. The leaks at the collector are not unusual. I just installed a new muffler on my S2, and used my old standby - copper RTV. It's designed for header gaskets. I put a good bead around the header collector before I slip the muffler over it, making sure there's good coverage all around the joint. You can also add a schmear to the expansion slit...or adjust the clamp so it covers more of the slit. Install in this order, giving a wiggle to all the downstream parts after each step to keep everything aligned: - attach ALL fasteners LOOSELY, from heads to rear muffler strap - tighten the rear head port nuts first, to spec - tighten the front head nuts to spec - tighten the front header "Y" hangar - tighten the collector to muffler clamp - tighten the rear muffler hangars | ||

Conv90 |

Rat, I really thank you. Sincerely I never used tapered gaskets and I never saw wet sot on my sportster escaping from the exhaust in 30 years. I ordered a set. Sure, this Buell has been used so little by the older owners, and I'm sure there is a good amount of carbon build up on heads/pistons. Curious is that gases (with black wet liquid) are traveling from the muffler to the header junction in a reverse way. Gases can choose a better free way to the big opening at the rear instead of the little minimal opening at the front. BTW I was afraid of fatigued rings (oil traveling past rings) so I made a compression Test. the plugs are black really black and wet, I'd say fouled. BUT i have no problems, not on staring nor on driving. NO symptoms typical of fouled plugs like miss or stall or no start. Results are high (I don't know the factory specs ...the FM says 120 psi and i think it'a value too low. I have 2 tester one is reading usually more and the other less. I have front and rear between 185 to 210 psi (both). so It's about 190-200 psi. A bit in the high side (maybe too much carbon build up). I don't know which cams has it , but I doubt the older owners changed stock S1W cams with cams with less duration or anticipated closing intake. | ||

Ratbuell |

You could be fuel-fouled on the plugs, which would also cause the sooting. Check your jets. My S1W - stock engine, stock carb with jet kit, full race exhaust, and race air cleaner (carbon fiber oval) - runs (I'm pretty sure) a 48/190 combo. Possibly 45/190. 2.5 turns out on the idle screw. Gases will take the path of least resistance, and there is always some backpressure in a muffler (hence, "muffler"). Some of it will come out the gap in front. Not an indicator of a problem. If it were me, with a used race kit...drill the rivets on the rear end cap and check the packing. I pack mine with steel wool instead of fiberglass - mellow sound, lasts MUCH longer, and keeps that center baffle from breaking loose by flopping around in there. I think it's the rear cap. Might be the front. Someone can chime in, maybe? One of the caps has a "snout" for the inner baffle to slide onto; the other has the baffle attached to it. You want to pull the "snout" end so you can pack around the baffle. Been a while since I had to repack mine though so I can't remember which is which... Compression sounds about right. Change the plugs, check your jets, and run some good gas through it for a couple tanks. (Message edited by ratbuell on November 05, 2022) | ||

Conv90 |

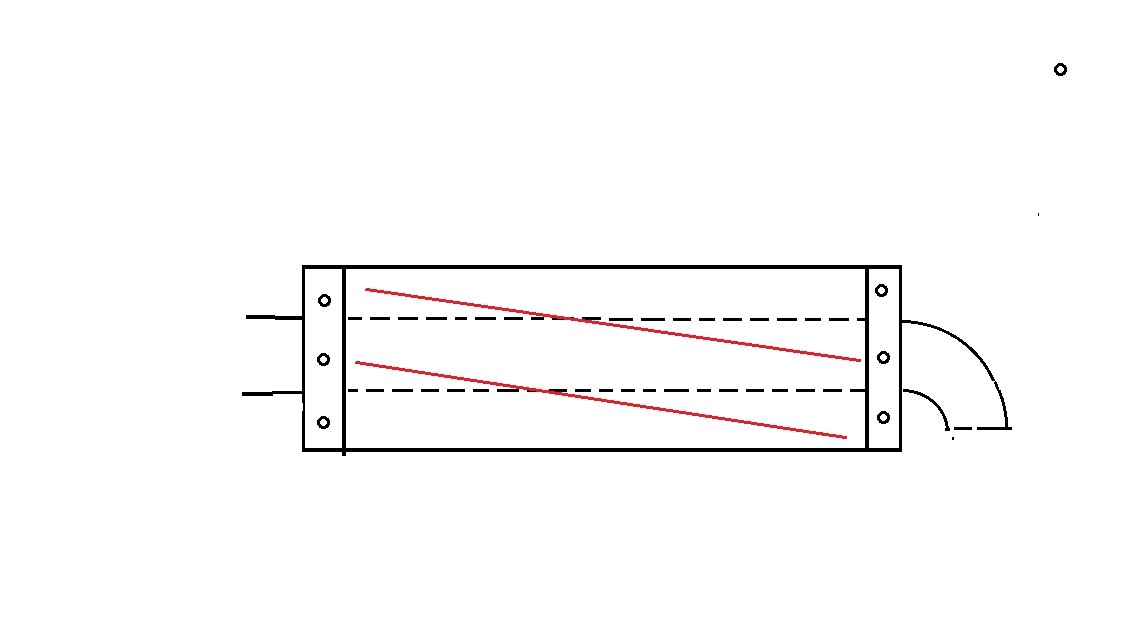

Thank you Ratbuell, About jets I have not really checked because I had an invoice sheet by the previous owner about some work done before to sell the bike to me. This list in the invoice says 42 slow and 190 main. But I doubt they are the jets installed. when I checked the slow jet screw (just to be sure that it was not too lean before to install the pro race exhaust) I noticed it was at 1 3/4 out. too little in my opinion. So i tried to enrich going to 2 or 2,5 OUT. But when I performed the "Screw in" to lean it and see the original position, I noticed that it started to stumble only when fully screwed IN. So For sure it's not a 42 but at least a 45 or 48. So when I performed the "screw out" regulation, I ended at 1,3/4 OUT . Exactly like it was before. SO I can't say It's too rich. About the race muffler I don't understand what you mean. When I bought it the guy that sold me the muffler, he told me it was "just Repacked" . Actually it is very quiet (not so louder as I was thinking...). Are you telling that there is the possibility that the perforated center baffle can go out of axle ? so loosing the front (or the rear) concentricity? Something like this?:  (Message edited by Conv90 on November 05, 2022) | ||

Ratbuell |

Correct. If the muffler is run too long without packing to hold the baffle in place, the vibration can crack or break it. I'd verify the jets, and check the muffler...just to know what's up and where you're starting from. | ||

Oldog |

Joe you put the header gaskets on the headers first? I never tried it that way.. learn sumpthing new each day. I cleaned the ports and hand fitted them to the port tapered side face out, then installed the rest as you outlined. ( X1) | ||

Ratbuell |

Depends on the gasket you're using, but yes, I have had them slide over the header first. Some have a tapered face that go in the head first; some are a squared-off donut that go around the header and press up against the flange that the fastening ring butts against. | ||

Conv90 |

Exhaust gaskets not yet here. I'll post the results. About fuel fouled plugs, I don't think it's fuel. No smell of fuel. I think more condensation mixed with carbon. That's strange because I have other 2 Sportsters with different carbs (the '75 with a SU carb and the '90 with a Mikuni HSR48 and both not vented through heads) stored in the same ambient . Sportsters are with junctions even loose and I have some black burn stripes on mufflers but not black liquid leaks. | ||

Conv90 |

Ratbuell, I think these are your pictures and I found them really useful. http://www.badweatherbikers.com/buell/messages/476 23/747345.html?1409024551 A question? the header mounting shoe , attached to the factory Y hanger, needs to be welded to the header OR it can be only retained by a metal clamp similar to the one at the the muffler-header joint? I installed the headers with new tapered gaskets I tried to put them before on the header, but with no success. I tried , but when i put the combo in the head ports I loose the control on when the gasket is sitting. (I crashed one because it was inserted not perfectly perpendicular). So I inserted (with no problem ) in the recessed space around the head ports. Yes it seems they are holding now with no more liquid blake things escaping out. But I'm still a bit concerned on attaching the pipes on head ports. The pipe edges are so sharp, it seems they are cutting the gaskets. Once I torque down the clamps, I feel the pipe entering good in the port housing , but I never reach a decent torque feeling . it seems it continues to be really simple to turns the bolts (it's because the sharp edges are cutting a bit the soft gaskets). It's difficult for me explain it in plain english... I noticed a thing: The ThunderStorm heads are with very LITTLE exhaust ports ... I measured them and the big diameter (where the pipe is inserted in, is about 48 to 48,5 mm and the diameter of the port is only 37,5 mm I measured the same dimensions on a pair of 883 heads I have in my garage and the outside diameter is the same (48,5 to 48,5mm) but the exhaust port is more than 41mm. I'll post some pictures later | ||

96s2t |

Was chasing a rich condition on my 2001 S3 with pro series and eventually found that the baffle bolt had vibrated loose and the baffle had slipped out and partially blocked the muffler exit. Check out the shiny area on the baffle and the inside of the end cap.  | ||

Ratbuell |

That's a different pipe than the race pipe. The pro series was an internal disc supertrapp; the race pipe is a perforated baffle surrounded by fiberglass packing. | ||

Conv90 |

I promised some pics The gasket on the header:  The gasket on the port. See how many rooms there is  See how bigger are the 883 Exh ports compared to the ThunderStorm heads (Same gasket used on the other picture)  The perforated baffle From header to exit: It seems good aligned  | ||

Conv90 |

Ratbuell, I think these are your pictures and I found them really useful. http://www.badweatherbikers.com/buell/messages/476 23/747345.html?1409024551 A question? the header mounting shoe , attached to the factory Y hanger, needs to be welded to the header OR it can be only retained by a metal clamp similar to the one at the the muffler-header joint? I installed the headers with new tapered gaskets I tried to put them before on the header, but with no success. I tried , but when i put the combo in the head ports I loose the control on when the gasket is sitting. (I crashed one because it was inserted not perfectly perpendicular). So I inserted (with no problem ) in the recessed space around the head ports. Yes it seems they are holding now with no more liquid blake things escaping out. But I'm still a bit concerned on attaching the pipes on head ports. The pipe edges are so sharp, it seems they are cutting the gaskets. Once I torque down the clamps, I feel the pipe entering good in the port housing , but I never reach a decent torque feeling . it seems it continues to be really simple to turns the bolts (it's because the sharp edges are cutting a bit the soft gaskets). It's difficult for me explain it in plain english... I noticed a thing: The ThunderStorm heads are with very LITTLE exhaust ports ... I measured them and the big diameter (where the pipe is inserted in, is about 48 to 48,5 mm and the diameter of the port is only 37,5 mm I measured the same dimensions on a pair of 883 heads I have in my garage and the outside diameter is the same (48,5 to 48,5mm) but the exhaust port is more than 41mm. | ||

Upthemaiden |

I don't have any experience with those headers, so I'm just throwing this out there, but if it's that sharp, is there any reason you can't take a file and knock the sharp edge off of it? Don't file it down so far that you get fitment issues, but if you just made the edge a little more blunt that it wouldn't cut through the gaskets so much, I assume there's enough flex in the pipes that they could make up the extra 1/32-1/16 when you tighten them up. | ||

Conv90 |

Upthemaiden I thank you. Yes I thought it. File it a bit adding even some rounding at contour. Now it's holding good so this will be the next move if it starts to leak again. | ||

Screamer |

Since it sounds like you’ve been able to get the system mounted, this info probably a moot point. The later manufactured race headers used the bulge-type head flange - and the earlier versions typically had the welded head (blunt) flange. The bulge type head flange generally has more successful leak-free installation with the tapered gasket. The welded flange can seal successfully with either, but with the tapered seal, it often pushes excess material in to the port - restricting flow. Using the adjustable mounting shoe (mounts with a band clamp), allows for the variability in fitment from header to header - no welding needed. (Message edited by screamer on November 15, 2022) | ||

Conv90 |

Thank you Screamer, These are very helpful advices/infos! For now the gaskets are holding good. I buoght 2 pair of tapered gaskets, so next week I'll check for protrusion in the ports. About the mounting shoe, I see that if clamped good with the band clamp, it stays fixed without the need to weld it. It's this:   | ||

Phelan |

That flange shoe is what you want to use rather than welding flanges to the header. There are 2 reasons Buell used those for the race headers. One is as Screamer said, to allow for variability in fit. But the more important reason, is to avoid work hardening the header where the metal is already harder from welding a flange tab. Flange tabs regularly break in this type of application. The show and clamp allows the vibration hardening to dissipate through the entire circumference of the header, so there are no hardened spots to break, except the tabs on the shoe, which is much easier replaced or repaired. | ||

Conv90 |

Phelan Thanks! the better fitment I achieved it's like this:   | ||

Brother_in_buells |

Have a look at this thread, http://www.badweatherbikers.com/buell/messages/476 23/687123.html?1347230959 The post from kevmean from the UK is a really good permanent solution for the tubers with race exhaust systems! | ||

Victory |

Valve Size and port sizes are never the whole story. Lets take a crud example. Harley Panhead I think during the bastard years starting in 55 or 57 the intake ports were increased for the panhead and maybe the exh too. Before then the 1948 Intake ports were smaller and you know what? Those were the ones preferred for racing. The intake path on the panhead is very poor with the T SHAPE. So for racing sure the bigger valves were added but it was the VELOCITY of the -48 smaller intake heads that made them preferred over the bigger ported heads later on. Yes its against everything we hear on a chevy block but that is the case here. The most important thing is that all parts and paths match in an engine build. Not what we think should make sense. | ||

Conv90 |

Unfortunately I still have this strange wet black thing coming out from the junction between the muffler and header.  |