| Author | Message | ||

Conv90 |

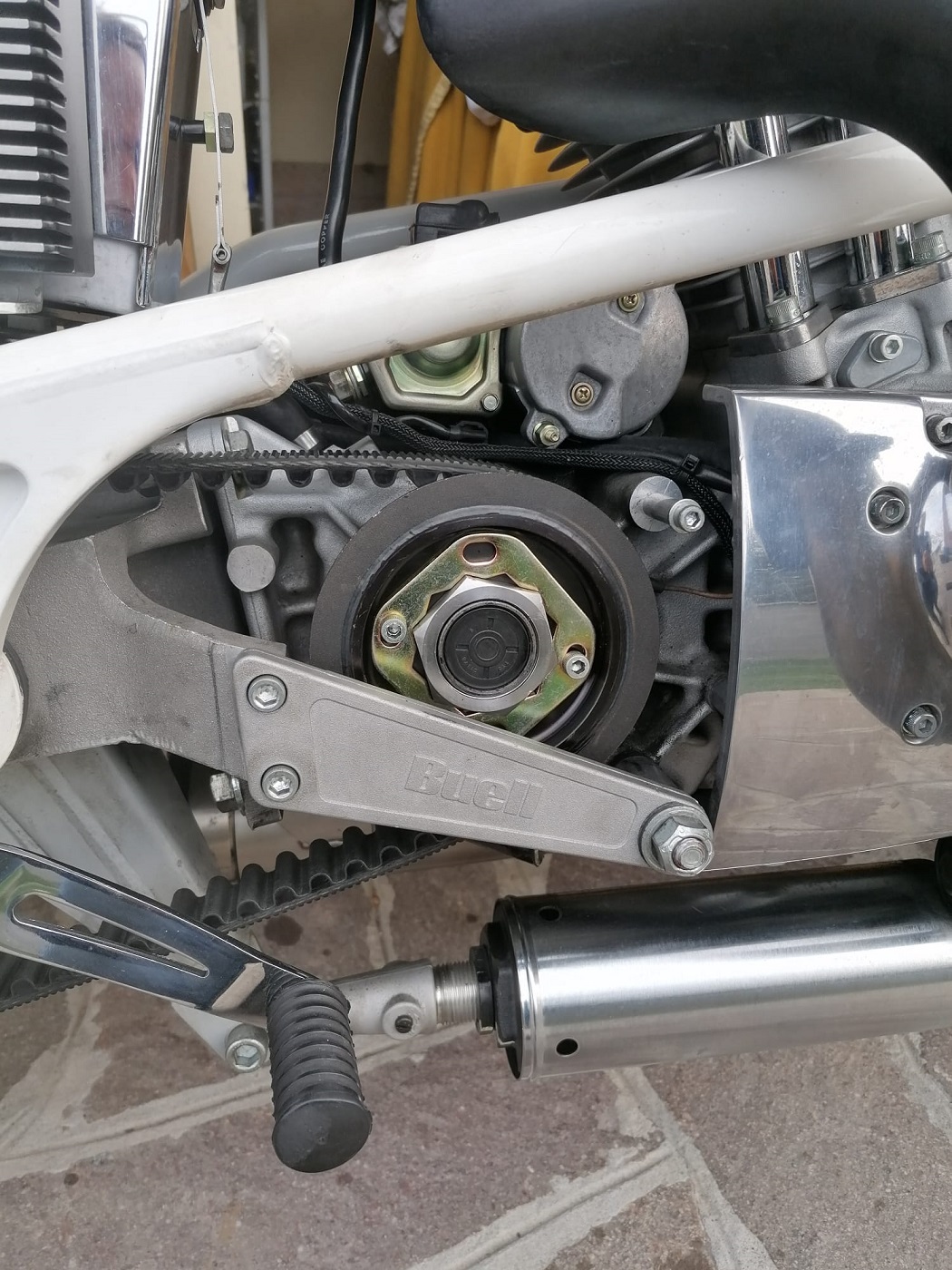

Just removed pulley to check for spacer, seal and splines conditions.... The pulley was moving/rotating only for interference and for the remaining part of splines . | ||

Two_seasons |

Yup, this is good engineering. The pulley is the sacrificial part! Can you imagine if the spline was!!! Easy peasy to fix.  | ||

Conv90 |

So the order of a 27T new Pulley now make sense..  | ||

Two_seasons |

And remember to follow the service manual for initial torque and final torque.  | ||

Conv90 |

Two_seasons, ...If only my Torque wrench can operate in counterclockwise ... Many torque wrenches are not allowed to measure the torque when used counterclockwise. BTW: new NUT/locknut quad ring and pulley (27T)  | ||

Led |

YUP! The first thing that went on my bike. I tried to do a "burnout", without flipping the whole bike backwards. Stripped all the teeth right out of the drive sprocket!! | ||

Falloutnl |

Conv90, keep an eye on that nut. You'll hear a clear clicking sound at regular intervals when coasting at low speeds (at least, that's when you'll be able to hear it) if the nut's backing off. It's reminiscent of worn out wheel bearings. That nut has to be torqued down with a ridiculous amount of force. If you're unsure whether you were able to do so, keeping an eye on it is a good idea (if you don't want to have to buy yet another pulley). I had something similar happen on my S1 this year. By the time I realized it was the nut of the front pulley, the teeth were worn enough to create a fair bit of play (not on the spline thankfully). | ||

Upthemaiden |

You might have to use the trick I used when I was installing the sprockets inside the primary. I figured out how much torque I needed, used my 2ft breaker bar for leverage, did the math with my weight to find the exact distance from the pivot point that I needed to stand on it to get the exact torque the nut needed. Also, side note, it's amazing how much a painted front pulley cleans up the right side of these bikes. My pulley is rusted and horrible looking and is an eye sore for sure. | ||

Conv90 |

Falloutnl, thank you for your advice. IF I made something incorrect on tightening the nut ... I did it wrong on the tightest side  . . But for sure I'll recheck while i find the way to reverse the torque wrench. | ||

Conv90 |

Upthemaiden, I thought the same . the FSM calls for tighten the nut to 50 ft-lbs (68 Nm) INITIAL torque, then additional 30°-40°. 68 Nm are 6,9 kgm. Having a bar 1 meter long and apply about 7 kg. BTW I have found the way to switch the torque wrench. I need only to remove an E-clip and reverse the 1/2 square drive at the head of the wrench. Unfortunately now I have not a E-clip remover (or better a new E-clip to replace) | ||

Upthemaiden |

50ftlbs isn't bad. If you've got a foot long ratchet I'll loan you my 6 year old to stand on it. | ||

Two_seasons |

Conv90: Pulley, nut, plate. I got new screws too for a couple more $. As described, when the pulley is loose, on take off from a dead stop and slowing down from 25mph to a dead stop, you'll hear squeeking coming from the belt as it rubs the sides of the pulley. i too thought it was bearings going. My S2T got new wheel bearings and it was still there. Oh well, I'm not too proud to say i shotgunned it  | ||

_buelligan_ |

Jim’s Mega Nut are a really good upgrade for that stock problematic nut and lock plate. | ||

Xldevil |

Fill the spline with Loctite blue. .That will prevent future damages. |