| Author | Message | ||

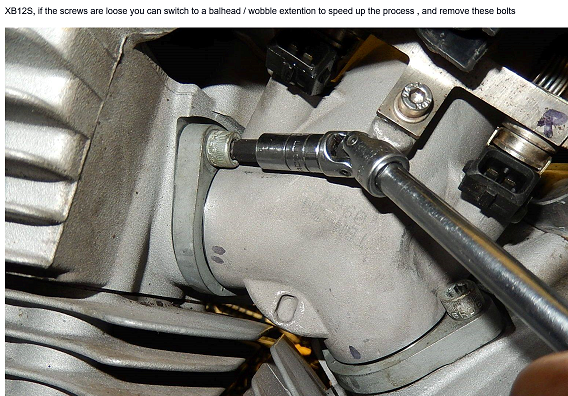

Upthemaiden |

These intake manifold bolts are something else. I tried to finally replace my intake seals since I had to rebuild the carb. I cut off a piece of a 1/4 hex key about half an inch long and used a combination wrench to twist it once it was in the bolts. I got the left two and right rear no problem, but that front one just isn't going for it. Previous owner must've jammed that thing in good, and likely rounded the inside of the bolt slightly in the process. I've also tried using a longer ball end wrench on it, but one twist and I think that just stripped the inside of the bolt head. Whoever decided to make that flange so small you couldn't just put normal bolts in it deserves to be smacked. Anyway, I've done a bunch of research online so I think I've found all the potential options for getting the stripped bolt out. Think I just came here to vent(although if you have any practical advice, feel free to share...). I've seen two people online saying the cut a slot into the bolt and were able to get it out with a big flat blade screwdriver, not sure if they meant using the screwdriver in normal fashion, but at an angle over the manifold, or if they stuck it on the bolt at a 45 degree angle and twisted it like a wrenc. Someone mentioned about grinding the head off of the bolt to remove the manifold/flange, then welding a nut to the stud and trying to twist it out that way, not sure if I'd be able to get anything into that tight spot to actually grind it... I also thought about trying to file two flat sides onto the bolt and see if I can just get a wrench on it that way. Worst case scenario I assume I'd need to cut the manifold in half to get it out to have more room to work, or pull out the engine and remove the whole top end as another way to get better access to that bolt. Always happy to take on a project, but ideally not at the end of May with a newborn in the house, meaning I'm lucky to get a few hours to work on that stuff in a week when I should be out riding. | ||

Hootowl |

It's possible that if you remove the bolt head, the stud that is left will back out, as the head holds the threads in tension. | ||

Ebutch |

Try some heat pencil tip torch map gas and short straight allen with allen ratchet handle.  I've done this cut down allen wrench on short side too about 1"then on long side of allen use a small dia 1' pipe too brake loose. It will work ! (Message edited by ebutch on May 28, 2017) | ||

Akbuell |

Another possibility might be the evil, hated easy out. You already have a (shallow, I know) hole drilled, so a 3/8in or so diameter tip easy out might do it. You only need to break it loose. And with the addition of heat . . . Hope this helps, Dave | ||

Steveford |

Sounds like Loctite was used. Try some heat and a really good smack with a brass drift on it. Do NOT use an EZ out on anything, it'll snap off and then you're screwed. | ||

Phelan |

If you're anticipating doing them a few more times over the service life of the bike, and are serious about rectifying the problem, you can always install 08-10 heads and flanges. Thr bolts are all 1/2" hex head and further out so you can fit a ratcheting wrench on them. | ||

Phelan |

I just noticed you're riding an S1. First off, be glad it's not an XB, as the intake takes a lot more work to gain access (rotating the motor). My comment still applies, but you will also need a new front motor mount that fits XB heads, like the one Hammer sells. You wpuld use 08-10 XB heads (and flat top pistons or XB pistons) and drill/tap thr breather holes, or 07-up XL1200 heads (which already have breather holes drilled and tapped) with flat top or XB pistons. | ||

Alfau |

Picture is a twin motorcycles tip. My thoughts:- If all else fails, a very sharp coal chisel to loosen. | ||

Upthemaiden |

I appreciate all the advice! There's some good tips in there... Hootowl, that's my hope. My only concern, because of how tightly everything is wedged in there, is that if I cut the head off, and I happen to still not be able to wiggle the manifold out, there'll be zero hope of getting that bolt out because there's nothing left to grab onto, short of cutting the manifold flange. Ebutch: I tried some heat with mapp gas, no luck but I'll definitely keep using that one as most people who were dealing with stubborn ones usually said the heat helped. Steve: I thought about the possibility of loctite, but there wasn't any on the other 3 bolts, so I'm hoping they didn't randomly add it to this one for no reason! Phelan: I love the idea! but if I had the money to throw at my bike like that, I probably would just take my bike somewhere and pay them to get the stupid bolt out haha. If I had the mechanical knowledge to upgrade my motor as far as to replace all of those parts with XB parts, and know which pistons to match with what, and where to measure the squish band and deal with compression, and all the other things I see people talking about on here, I bet I probably would've been good enough to get this bolt out somehow already. Alfau: Tried that one! Unfortunately the carbed manifolds are rounder and more in the way than the EFI bikes, so my wrench was at even more of an angle, and as soon as I put some torque on it, it just twisted the wrench right out of the bolt, rounding it a bit. After thinking about it all day, my decision is just to wait on the intake seals. My bike has a hiccup/sputter at 3k rpm when I'm just cruising at steady speed. I'm hoping it's a needle issue and a carb rebuilt and checking out the needle/jets might solve it, and wanted to replace all the seals while I was at it to make sure nothing was leaking. At this point, at the risk of being without the bike for weeks(or months, remember the newborn in the house....) at this time of year, I'm just gonna spray a little Ruglyde on the rear seal, tighten it all back up, rebuild the carb and ride it for the summer. I've already got a lot of stuff I want/need to do to this bike... including all of the usuals: primary tensioner, brass oil pump drive gear, clutch grenade plate, shift detent plate, clutch cable, front & rear isolators, aluminum swingarm... I would've wrestled all that stuff on with the bike together. I'm thinking maybe it'll be easier to wait until fall, pull the engine out of the frame, pull off both cylinders and replace the gaskets while I'm at it. While I have them off it should be easy as can be to get that bolt out, and this way I won't have all the downtime. I already know the bolts holding the heads/cylinders are pretty nasty looking, so hopefully I don't run into a similar situation with those come spring. I really need a second bike for the sake of wrenching at my own pace. | ||

Steveford |

I really need a second bike for the sake of wrenching at my own pace. Well, yeah! P.S. If not Loctite, just corrosion is screwing you up. You might just be able to grab the head with some needle nose Vice Grips and bust it loose. That whole intake is just a horrible design. | ||

Harleyelf |

It's not that expensive a part - the stuck side is facing out so you can get a grinder on it - once the manifold is off you can grab the remaining stud with vise-grips and it should turn out easily, especially since you have heated it. Manifolds are on e-bay for around thirty bucks. You might even be able to save the one you have by delicately grinding just the head of the bolt. Just make sure the remaining surface is parallel to the lower surface. | ||

Ebutch |

Put allen tool in man-bolt use a 1/2" x 1' helper pipe too Brake-loose and make Sure your on it solid ! I will loosen with a Snap !  | ||

651lance |

I went to twelve point bolts and they are easier to get on and off. | ||

Upthemaiden |

I originally planned on replacing all 4 with normal bolts, until I got in there and saw how tight the space was and knew that no normal bolt would fit. Do you need a special proprietary Harley wrench to pull off the 12 point bolts, or does the 12 point side of a combination wrench fit it? Are they shaped like the bolts in the head for the studs? Are they something you sell Lance? I've got an order to place in the next month or so, and if you have them, I'd definitely consider switching to those instead. Ebutch, I didn't follow any of that haha. 1/2"? my bolts take a 1/4" wrench. What's a man bolt? and is that the picture you meant to post, or did you upload the wrong one? No need for political garbage in the old school forum. | ||

Ebutch |

Man= manifold bolts  | ||

Loose1 |

I don't know if the size is right but something like this. http://www.ebay.com/itm/12-Point-Flanged-Bolt-Stai nless-Steel-FT-5-16-18-x-1-0-Length-4-Pcs-/1116719 45984?hash=item1a002aab00:g:~qIAAOSwwE5WXvWC | ||

Upthemaiden |

Also... just because my gas tank wanted in on the fun... the paint has survived great on my tank. I assume it's already a recall tank because it has the elevated stickers, but it only had a few tiny bubbles that didn't bug me in the slightest for a 20 year old bike. I pulled the tank off while I was working on it and set it aside. I came back today, 2 days later and noticed I must've had some kind of gas fumes leaking out of the breather valve, and a huge chunk of the paint swelled up. Lesson learned. Any time you pull the tank, put a hose on the air valve. On the upside, when I first bought the bike, I had planned on repainting it, but then I figured with as nice of condition as the paint was, it'd be a shame to mess with it. I guess there's no shame now. I already planned on repainting the frame and wheels, most likely the same color. Lately though I've been checking out more of those molten orange/nuclear blue bikes, so maybe I'll give that a chance. Not sure if the colors are a little too 90's for me, but it definitely looks good. Until then, I might just scrape off the flaked paint and put a sticker there.  | ||

Upthemaiden |

Thanks Loose1! Those bolts definitely look better. I'll track some of those down before next time. | ||

651lance |

That's the correct style. | ||

Upthemaiden |

Is regular stainless fine for those bolts? They don't get torqued down that hard, so I can't assume that they need to be excessively strong. | ||

651lance |

That's what I've been using for years. | ||

Ralph |

You can probably find those bolts at Fastenall or McMaster Carr for a lot less money. I don't have a big problem with the Allen heads - they're a pain, but it's not something you have to get into very often. Personally, I agree with your idea of putting the other three back in and riding for the season before messing with it. Why get into a bigger project when it doesn't have anything to do with the problem you described? Just cross your fingers that the seals haven't broken loose and get pinched when you tighten it back up. To bad about the tank. Looks like a perfect reason for a racing stripe. You've been thinking about an XS650 - get one when you have a chance. Just remember, it'll make you appreciate how modern your Buell is  Ignore Ebutch photos, he throws up random stuff that has nothing to do with the conversation. It makes him happy and it could be worse. | ||

Ralph |

Here's a link to McMaster Carr; https://www.mcmaster.com/?m=true%20ForceRecrawl:%2 00#12-point-screws/=17ufkwv Scroll down a bit to the stainless bolts - $2.66 each. Not beating you up Loose - I'm sure that was the easiest/fastest way for you to find them. Crap, now I'm thining about using them... By the way, another way of dealing with the stripped bolt would be to jam that cut off wrench section into it and have a nice person put a couple tacks of weld on it with a mig. Not something I'd ever think about normally since I've never used a cut off stub to take them out. I use a bent allen with a standard end and ball end along with a cut down standard allen wrench. My concern is that the head and bolt were cross threaded or something worse. If so, it may take some surgery to fix it, ie no riding for awhile. (Message edited by Ralph on May 30, 2017) | ||

Upthemaiden |

Good thinking on the racing stripe! That could be a good fix. I could try to stick one on with vinyl, wonder if that would start cause any bubbling issues under it if it was trapping fumes under it. The front seal hasn't budged obviously. The rear flange is spinning freely/smoothly, so I think the seal is probably in good shape, I'll spray some lube in there before I tighten it up. I'd love to get an xs650 someday, but an early 90's gsxr project is gonna have to come first. I'll see what I can find when spring rolls around. Either way, both of those bikes are going to be serious projects, so unless I find one in decent running condition first(which I'm trying not to do because I know people feel the same way about the old GSXRs and XS650's that we do about people chopping up tubers, so I'd feel bad ripping into a decent shaped bike), the S1 will have to be the runner while I work on that bike, so it'll have to get all of it's problems fixed before I have a second bike anyway. Thanks for the link! I see some 5/16-18 x 1" bolts listed at $2.66. Can anyone confirm the size bolts before I order? I compared mine to some spares in my nuts/bolts drawer, it looks like 5/16-18 is right, but mine were only 3/4 long. I wasn't the original owner though, so they could've been replaced at some point. If I order some day they should make it here before I get time to put the bike back together. | ||

Akbuell |

My X-1 parts book lists the bolt as 5/16-18x 3/4" Easy to make a 1" bolt shorter. | ||

Williamscottrobertson |

Maiden, If you have a fastenal near you they may have them in stock. I know I'm a far cry from PA but, I have a 79' CX500 custom that runs and drives, id let it go right, if you're interested. I was going to do a cafe build on it. I just love the longitudinal v-twin and shaft drive. I have a deluxe tank for it also. | ||

Upthemaiden |

Thanks William, but I think my heart is set on the XS650. I just think it's a great looking motor in a time period when everything else was typically pretty boxy and ugly. I'll consider a Honda CB500T when the time comes around too, but unfortunately most of their other CBs were all 4 cylinders, which doesn't have the same appeal to it. I haven't entirely decided what I'll end up doing with it. I originally got interested in them when I got tired of my speed triple in traffic for commuting, and I wanted something a bit shorter for stop and go traffic, and something not quite as fast, so I could actually get a chance to twist the throttle on my commute. I like looking through the hardtail builds, I've seen a few builds with front/rear suspension intact, but good looking ones are much harder to come by. I'd still want to keep fenders and all the lights/signals since I'd be using it as a commuter. I've seen some dirt track style bikes that look fun, and the more I look at them, the more I can appreciate some of the original styled bikes, but of course that would completely ruin the point, because what good is a project like that if you're not cutting and welding things how you want them. I did actually see a CX500 yesterday parked in the lot when I went to the food store. I checked it out as I walked past, it was a nice looking bike. I believe I do have a Fastenal. Mcmaster does always ship things super fast, I just hate not knowing what the shipping is going to be until after you click submit. That's a bit of a gamble when you're already paying $10 for 4 little bolts haha. | ||

Hybridmomentspass |

Yeah, those bolts blow. Also, I hate the bolts for the pushrod tube bases... Or maybe I its the bases themselves. Either way they are a big headache! | ||

Upthemaiden |

I haven't heard one good thing about those pushrod bases. When I get to that point I'd definitely like to switch to some of the CNC bases and the collapsible pushrod covers. | ||

Upthemaiden |

Happy to report that even after 3 of the manifold bolts had been pulled out, I was able to spray a little lube on the seals and tighten them up without any issues of the seals binding/moving/tearing, and everything still seems to be working well. I didn't get to check for leaks because it was late by the time I finished last night, but the bike is running well, so even if it has a leak, it'd have to be a small one. On the down side, I cracked off a small piece of the main opening on the manifold as I was trying to adjust it back in to position, which you can imagine isn't the easiest with one bolt still tightened. I was worried that would cause me some air leak problems, but apparently not. I'll buy a new one before spring comes out, and now I won't have to feel bad about just cutting this one out, which will give me easy access to that stuck bolt without having to pull the whole top end apart. Huge plus is that my choke works for the first time since I bought this bike last year. It's so nice to just pull a lever and have the bike fire up, instead of having to turn up the idle, and constantly adjust it down until the bike is fully warmed up. The 3k rpm stutter I had is also gone. I put two shims under the needle, about .06" worth, and that took care of it. |