| Author | Message | ||

S1owner |

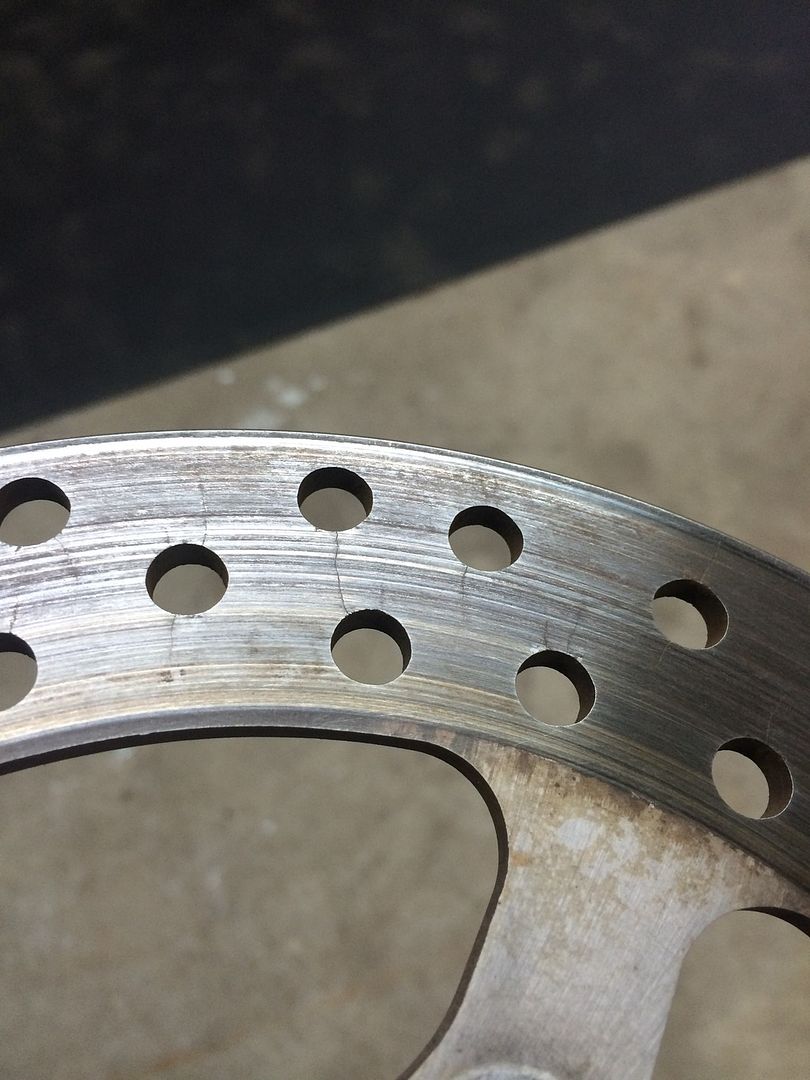

Ok this is for thise of you that think I will drill holes in my rotor because it looks cool or instead of buying one that has them. This is a rotor that came on my XB wheel that the PO had drilled. It looked fine but I cleaned it and rubbed it out with Steel wool and you can see all the hailine cracks. Needless to say its junk    | ||

Ft_bstrd |

Wow! | ||

Brother_in_buells |

Have seen this with hard used disks to! Are You sure about the drilling and what size are these holes? | ||

S1owner |

Def done by someone other tgan the manufacturer. Inconsistant no pattern you can feel the raised edge | ||

Ratbuell |

My only question is...."WHY?" Cross-drilling looks "cool" to some people but causes weaker rotors, as shown here. SLOTTING allows braking gasses to escape. But of course, you can't homebrew a slotted rotor... | ||

1313 |

Inconsistant no pattern The pattern matches an early XB (before being made compatible with the 1125's) rear rotor perfectly. It's an odd, somewhat irregular pattern, but it's there. The cross-drilled holes do look to be slightly larger than OE, however. If truly done 'after the fact' I'm somewhat impressed by how round the enlarged holes are... 1313 | ||

S1owner |

I cant promise either but if the early ones were like this I not in the know on that but there are an odd few that are extremely close to the edge and some holes are not through at 90 degree to the sisk while others are. Any way this is a bad rotor. | ||

S1owner |

Your are correct looking at pics online it appears it is factory drilled but still a bad rotor | ||

Court |

Wouldn't be the first time misdrilled holes were a problem. In 1997 we shipped 17 bikes that had the shock attachment hole, on the rear swing arm, drilled WAY (about 3/16") too close to the edge of the material. Fortunately ..... We found it and tracked down the units unshipped and unsold at dealers. | ||

Screamer |

Court, I believe you're thinking of the early 1999 aluminum swingarm? | ||

Mighty_mouse |

I did it to my '77 CB750SS back when I was a kid but I didn't go overboard like that and I also chamfered the holes to relief the stress cracks. Never had an issue. Might have to see if I can dig up an old photo now. MM |