| Author | Message | ||

Amahoney |

Hey folks I'm hoping somebody might have some insight. I replaced my base gasket and everything has been going back together nicely except for some rocker box bolts that keep snapping. The first time the bolt snapped it was one of the original bolts. Today I went to the local HD shop and purchased new bolts. One of the new ones snapped too. I'm following the torque specs from the service manual and I'm even using the low end of the specs. Has anyone run into these bolts snapping before and if so what did you do to get things back on track? I've gotta be missing something simple... I hope  Thanks guys!   | ||

Kilroy |

Those torque values are in "inch-lbs" not "ft-lbs". A lot of people make that mistake the first time. These aren't head bolts- they do not need to be torqued much at all. | ||

Buellistic |

12 inch pounds in every FOOT pound, do the math ... If you are an MECHANIC you do proper torque'ing, IF YOU DO NOT CARE, AFTER ALL IT IS YOUR BUELL ... | ||

Thylacine |

Put down the torque wrench and step away from the vehicle. I don't mean to discourage you but if , in fact two were broken ,well then it is most definitely user error. But, this is the place to ask those questions. , a little ribbing comes with the knowledge though. From me anyway. But I won't hold it against you. Good luck! | ||

Ratbuell |

+1 on INCH-lbs. | ||

Buellistic |

Amahoney: PM me so that "i" can get your email address and you will get a lot of TECH. support HELP "INFO" !!! | ||

Amahoney |

Thank you Kilroy and Ratbuell! | ||

Blks1l |

So was that the issue, using foot lbs instead of inch lbs? | ||

Ratbuell |

If you were torquing to lb-ft...you may want to get new gaskets. Bet the ones you were using are smooshed flat as a cartoon Coyote's foot after he pisses off the RoadRunner  | ||

Foximus |

hehehe. | ||

Amahoney |

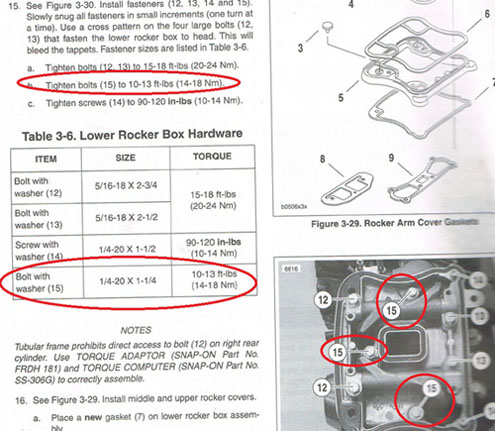

Thanks guys. I just got home from fishing all weekend so I didn't have a chance to check the service manual for what it had listed for torque. This pictures is from page 3-23 of the service manual and it says 10-13 FT lbs. Such is life.  | ||

Ustorque |

I was curious after you posted this because I just did mine and was certain the bolt you noted that you were having an issue with was torqued to ftlbs. To have 2 snap in a row@ 10ftlbs is really odd. What type of torque wrench are you using? | ||

Buellistic |

REMEMBER THIS !!! Just because it is in the FACTORY SERVICE MANUAL does not mean it is correct !!! Only a MECHANIC will know difference and a technician only knows what's in the manual !!! | ||

Kilroy |

I assumed the one in question was the one listed at in-lbs, since you said you snapped it twice. That is the reason 99 pct of the time. It is very unusual to snap the same one twice if it is not overtorqued. | ||

Jim2 |

If the manual were wrong I wouldn't think that a 1/4 X 20 bolt would snap at only 10 ft/lbs. This seems very strange. Your not using a torque wrench were 10 ft/lbs. is at the very bottom of the scale are you? If your torque wrench is 10 - 120 ft/lbs and you try to use it for 10 then it might be applying a much higher torque as the torque wrenches are only accurate in the middle of there range. | ||

Buellistic |

Jim2: Very good, you get an A+ ... | ||

Buellistic |

Kilroy: "i" am surprised that the TREADS did not come out of the head ??? | ||

Kilroy |

It has ben a while since I have done this. Are those bolts aluminum?? | ||

Buellistic |

They are HARD METAL and replacements can be bought at ACE HARDWARE ... | ||

Kilroy |

well that don't make no sense at all | ||

Knwyman |

Was the longer bolt accidentally placed into that hole? If the bolt bottomed out, it could easily snap w/10 ft/lbs applied. | ||

Kilroy |

maybe you forgot the washer? | ||

Oldog |

Please note from the fsm page, the 2 adjacent fasteners are 1/4 x 20 one tightens to inch pounds the other to 10 times that tension, I have to think Buellistic may be right the screw in the photo is wrung off, check to see if it is grade 2 or grade 5, those bolts are all steel, and case hardened to some degree, the steels chemistry dictates the grade and to a point how much tension you can put on it. I would get them from HD or fastenall the 3 small bolts just add more clamp to the box bottom gasket to prevent leaks. get a cheap beam type tq wrench for stuff like that... | ||

Kalali |

Its really not 10 times. Actually the specs are fairly close; 120 in-lbs is the lower end of the range for the other bolt which is 10 ft-lbs. Something wrong with the torque wrench or how it is being used. | ||

Radon30 |

I would have to agree with knwyman, seems bolt wasn't allowed to stretch, if bolt is dead headed it will snap . | ||

Buellistic |

If you are using a CLICK TYPE TORQUE WRENCH and you go past the CLICK or it has been "DROPPED" and never CALIBRATED !!! If you use the torque wrench as a working MECHANIC does, it should be re-calibtated every 90 days !!! | ||

Radon30 |

To be honest if you turned wrenchs awhile you know if you exceeded 10 ftlbs or not. I have had click style torque wrenches fail to click but I knew I was exceeding the amount of torque required. | ||

Dannybuell |

I have been told on the 1125 board; dry torque values for the sporty motors and wet for the 1125s. I have used anti-seize for years on threads for everything including the rockers. It has been my experience that the bolts slide in quite easily and will clearly stop when they have reached their clamping potential. | ||

Oldog |

I stand corrected Kal... tanks =) | ||

Buellistic |

TORQUE'ing compound is your torque'ng "FRIEND" !!! DRY THREADS INTO ALUMINUM GAUL'S THE THREADS !!! |