| Author | Message | ||

Knwyman |

Off the top of my head in MLV, you can choose one of the graphs to take a look at the ETS reading. I isolated this on one of the graphs as I suspected it was bad. It is called CLT if I remember correctly. There is also the voltage reading of the sensor as an option. If I get a chance later, I'll post a screen shot of what it looks like when it's bad. For any temp sensor, though, you should see a fairly linear trend w/out big jagged deviations. | ||

Bikerrides |

Yeah, it's pretty cool how you can do that. I put the ETS and ETS voltage on one graph, spark 1 and spark 2 on another, rpm and tps in another. There were a few times that the spark was off by one number between the cylinders (would that indicate a skip?), but it didn't always correspond with when it looked like the ETS might be acting up. I do know there were a few places where the ETS looked like it dropped 3-4 degrees and then back up. Then near the end of the time I was holding the engine at 3K, it spiked about 5 degrees over a few seconds. I'll see if I can get a screen shot of mine posted as well. If you and anyone else who can post a screen shot of what a bad ETS looks like in megalog viewer, it will help me determine if that is one of or the only reason I'm having these issues. Heck, a screen shot of a good one would probably help me, too. | ||

Bikerrides |

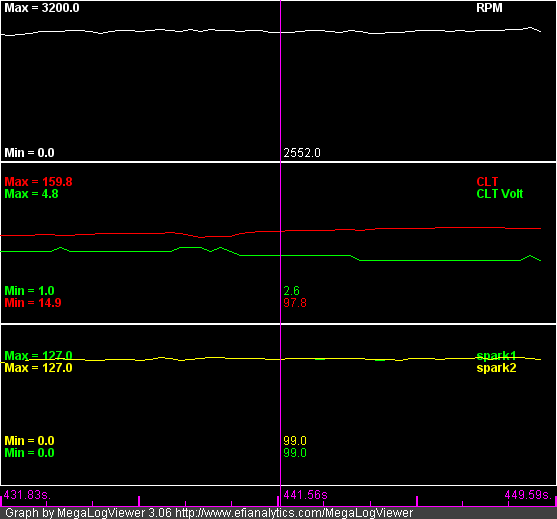

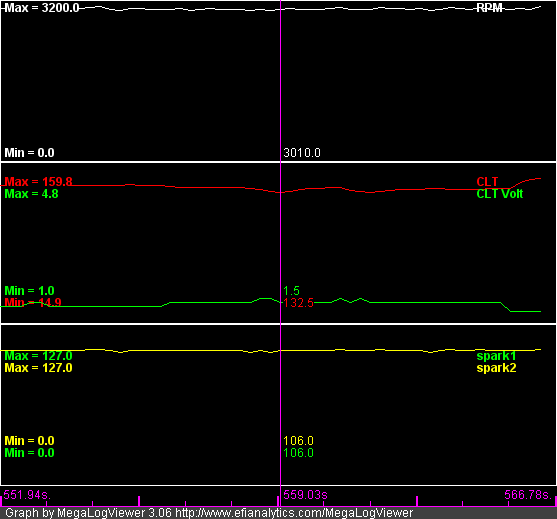

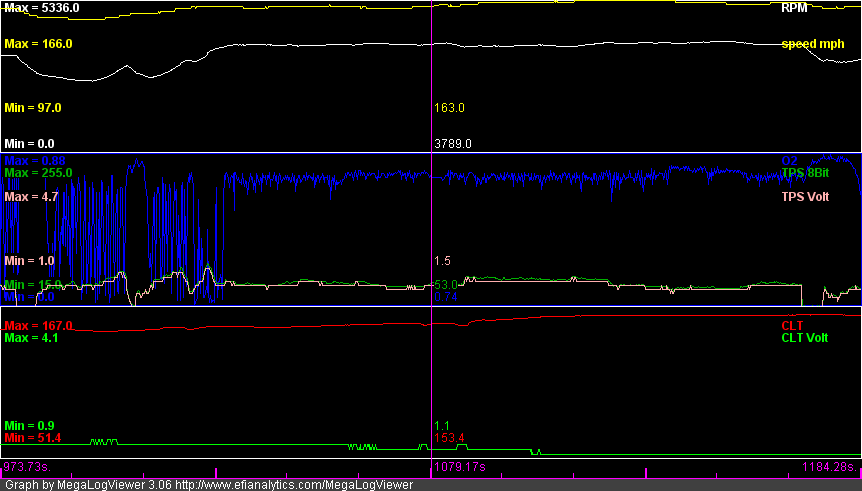

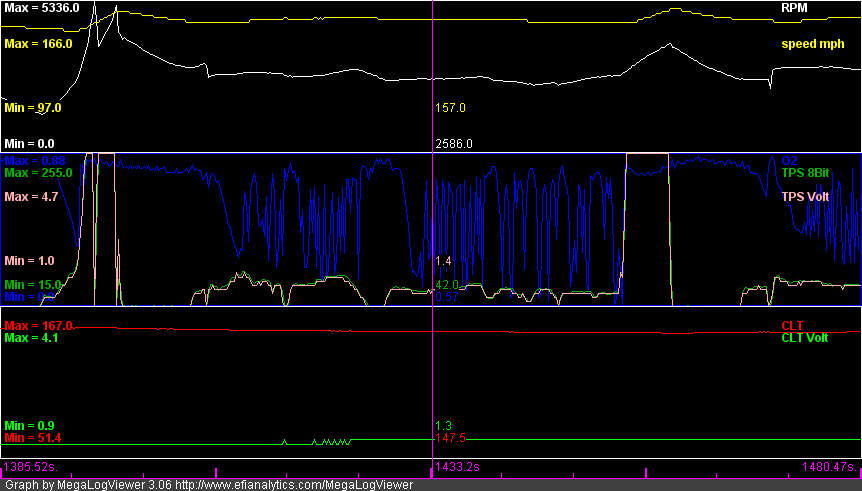

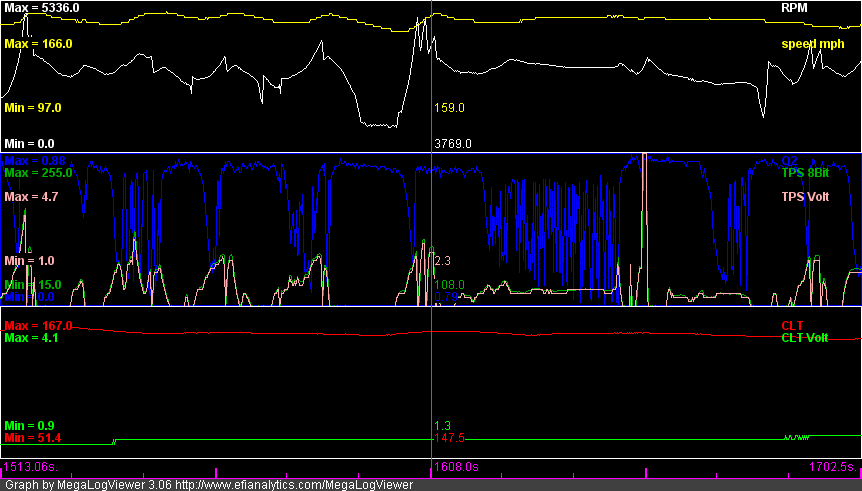

Here are a couple of pictures of the graphs on megalog viewer showing rpm in white, engine temp in red and ETS voltage in green (it is shown as CLT in megalog viewer), and the spark for both cylinders on the bottom graph. The first pic is when I noted this on 4/24: "Everything just ticked up 1 or 2 degrees at a time until around 95, then it dropped to 93 and back to 95 or 6; it jumped around 2-3 degrees until it got to 98."  The next picture is a graph from the point that I noted this on 4/24/12: "...then it was linear again until somewhere around 135. I had moved the rpm up to 3K or a little over before then and I began to notice the backwards movement by a couple degrees, then up 1 or 2, then back; it just kind of jumped around within a range of 3 degrees for a few seconds. I also noticed what seemed like a few misfires/skips in conjunction with the non-linear temp reading. When the temp got over 140, it became linear again."  Does anyone have an opinion on these graphs? Do they show the possibility of the ETS being bad? | ||

Knwyman |

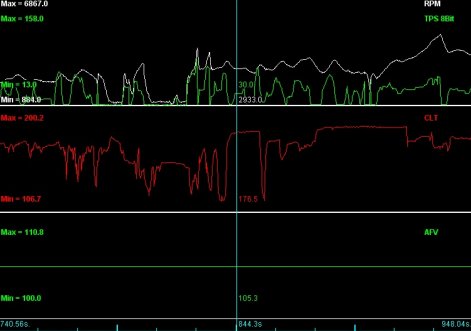

In the graphs below, you can see how screwy the ETS was. Yours looks good to me. I went for a ride after putting in my new sensor tonight & also have a bit of hesitation at 2500RPM or so. I pretty much never ride at that RPM unless I'm in first gear, though. With the new fuel maps however, rideability at low revs in first gear is phenomenally better. I think with more tweaking I can get it. Next up: Rocker box gaskets on the front head. Just noticed it tonight.  | ||

Bikerrides |

Kris,what are the new fuel maps you are referring to? | ||

Knwyman |

I made custom fuel maps for the bike. It makes a HUGE difference. You already have the tools -ecmspy & MLV. Basically you will do a datalog ride, have MLV do it's VE analyzer thing & end up with maps custom made for your particular setup. I'll pm you some links. | ||

Alfau |

Play with this..lol http://www.buellxb.com/Buell-XB-Forum/Do-It-Yourse lf-Buell-Mods/ECMspy-megalog-tunning Just to keep good things in one place :- http://www.badweatherbikers.com/buell/messages/32777/589313.html (Message edited by alfau on April 28, 2012) (Message edited by alfau on April 28, 2012) | ||

Alfau |

Kris, Could you pm those links to me too please? | ||

Knwyman |

Sure, but I think you've probably already seen them. Two of them are from the XB board -you already posted the link to one of them. | ||

Bikerrides |

Rode the bike to work yesterday. CEL there and CEL back home; skipping, popping, coughing, problems both times.  Back to square one! Man I wish I had been datalogging! Back to square one! Man I wish I had been datalogging! I pulled the codes and it says O2 sensor always rich. New O2 sensor a couple of weeks ago, so I'm not inclined to believe it's that. But something is causing the ecm to throw more fuel at the rear cylinder at a minimum. I took the ets out of the bike so I could take it down to napa and see if they had a compatible part; no dice. When I took the part out, this is what I found on the side of the wire that faces the engine; not visible when the part was on the bike and connected.  This could be the culprit and might explain why the bike runs good until temps begin to rise. I have the part off the bike right now and an ohm meter. I believe I've read on here, maybe in this thread, that the sensor can be checked w/an ohm meter. This is what I have.  I'm a HS music teacher and have very little experience working with an ohm meter, but understand the basic concept. I spent much of my teen years working in my father's machine/metal fab shop, but never really had to deal w/ohms and volts. Give me a lathe or mill and I'm on it; machined my own overdraw back when I was into bow hunting. I have a rather strong mechanical sense and may have enjoyed being an engineer more than a music teacher.  I throw that in so, you all will know you're not dealing w/a total mechanical idiot. I throw that in so, you all will know you're not dealing w/a total mechanical idiot.  Now back on topic. What should the ohms read? With the meter switched to ohms and holding the red lead on the sensor and the black on the connector, the reading fluctuates between 100 and 110. Don't know if I did that right or not, but I though I'd give it a go. If my method was correct, do the numbers look right? I'd also like to test the wiring from the ecm to the ets connection. How would I do that and what should the readings be? While I'm at it, I will probably do some testing for wiring shorts elsewhere. Someone mentioned using some kind of heat wrap or heat resistant tape to cover the wire as a temporary fix. Does anyone had success w/that and knows what will or might work in a pinch? Thanks for the help. I will not fail....dammit! | ||

Ustorque |

I really wish you the best of luck with your gremlin, I went thru the same issues with my XB about a year ago. Many of the same symptoms I hear you report are the same and it makes me cringe every time I see you say you may have found the issue and it happens again. I spent almost 1 full year replacing parts and diagnosing only to finally trade in my bike in defeat. Tech support at EBR even worked with me to try to resolve it. EBR's final opinion was if were in their shop they would start with a new harness and work forward from there. My XB was my pride and joy, but the inconsistancy of it's performance became more then annoying, it became unsafe. I would attempt to accelerate onto a highway and merge and the bike would cough or momentarily stall. I would replace a part and all would seem right with the bike and then minutes into the ride or a day later everything would come back again. The bike seemed to perform fine as long as the throttle was always being moved. As soon as the throttle was held in a constant position the bike would being surging and lurching, coughing. Many times feeling like i was toggling the stop/run switch while riding. It pisses me off just to think about it. I went from having a bike that I took such pride in making my own, to owning a bike that made me want to puke every time I opened the garage. I traded my xb in for my S3 and to date my S3 has been a pleasure, i'm hopeful i won't have it happen again. Obviously the FI between our S3's and the xb's are different in some ways, and my biggest issue with the XB was that it never threw a code for me to even begin a hunt. Over the year of poor running here is what I swapped out that never helped: Intake seals ETS TPS Coil pack Wires Plugs o2 sensor BAS ECM- I had 2 1 stock/ 1 race All connections were checked cleaned greased Like I said the worst thing was replacing something and having the bike run awesome, and then having the problem come back again. It gets very depressing and I honestly do wish you the best of luck. You have a beautiful bike there I hope you get her sorted out. Hopefully knowing someone else has been down this road before will help ya, and unlike me I'm hoping you succeed! Maybe it's worth it to ya to keep and eye out for a harness if all else fails. shawn  Edit: I'll also add that one of the biggest problems I had was that my issues hit right after the closure of Buell and conveniently enough many of the parts i needed were out of stock and on back order. Thanks to HD's fantastic dealings with their vendors. Some parts i waited months for. (Message edited by ustorque on April 28, 2012) | ||

Buellistic |

Have you replace the rear header gasket yet ??? The quick trouble shoot for the HEAD TEMP SENSOR is to DISCONNECT it and go for a ride !!! DOES ANYONE EVER CHECK THE ENGINE TIMING ANYMORE ??? | ||

Bikerrides |

How do I check the rear header gasket? I already tried disconnecting the ets and it didn't do any different. | ||

Ratbuell |

You don't "check" the header gasket. Just buy the $5 part and replace it. Hell, replace both while you have the header off. To "check" it, you need to remove the header anyway to see if soot is getting past the seal or not. While you're there, might as well put in a new one... | ||

Bikerrides |

Good point, Ratbuell. Do you know the part#? I doubt it, but is this a part that can be picked up at a local parts store? | ||

Jramsey |

H-D #17048-98 Some put them in the freezer for an hour before installing. | ||

Bikerrides |

OK, I'm headed to HD to get a pair of header gaskets. Any special advice/instructions on replacing them? Seems I've read something on here about something that holds them in place while getting the header back in place. Is this a fairly easy one man job? | ||

Alfau |

While your at the shop buying parts for fitting the headers, get four new retainer rings,two for the front,two for the back. There are two types of flange gasket for headers,tapered (original) and flat ones, I use flat type. It isn't easy fitting headers the first time, Follow the manual, make sure you do your homework; Do a search on BWB for fitting headers and read until your confident. Also in your pic,that heat sensor has been butchered with a crimp type fitting; best to buy a new sensor; you'll have to fit the correct coupling to your harness.(easy) Good owning a Buell isn't it? You start off happy with a full head of black hair and end up grey and bald,all in a short period of time. | ||

Jramsey |

"Good owning a Buell isn't it? You start off happy with a full head of black hair and end up grey and bald,all in a short period of time." Shit'n on another thread I see, well guess its about that time. | ||

Alfau |

Sorry for having an opinion. | ||

Bikerrides |

Well, the good news is that I didn't do anything today that made it worse or cost me a lot of money. Just time. Allen, I didn't read this until after the new gaskets went in, so no new retainer rings. The part number I gave was for the screamin eagle gaskets, which are the flat ones. I followed the FSM and hope that I did a good job. Here's everything I did today. I already mentioned pulling the ETS. I pulled the plugs and cleaned them; they were quite black from everything being made so rich. I also checked the battery voltage w/the multi-meter to see if I was getting the same reading as ecmspy. The battery seems fine; the PO put a new one in just before I bought it. I then decided to take the battery out so I would have better access to the cps connector plug. I tried to get it apart the other day and couldn't get to it well enough to disconnect the plug. W/the battery out, I was able to disconnect the cps and clean both ends of the connector w/contact cleaner; I put some dielectric grease on the plug as well. I then pulled the sprocket cover off so I could get a better look at the wires to the cps to inspect them for chaffing, etc. Didn't see anything obvious. I couldn't take the cam cover off because I don't have a way to pop rivet the cover back on, so I was only able to check the wire behind the sprocket cover. I also loosened the negative battery lead where it is grounded on the frame under the tank, sprayed it w/contact cleaner and re-tightened it. That's when I began to think about changing the header gaskets. Since everything was already out of the way and it was $10 in parts and a 20 min drive to HD, it just seemed like the next logical step in diagnosing and solving my running issue. I sprayed the nuts on the exhaust flanges w/wd40 before I left so it would have time to penetrate while I was gone. When I put the wrench on the first nut on the rear cylinder, I was very surprised at how easy it turned; it couldn't have been much more than finger tight. I'm not sure that I wouldn't have been able to remove it w/my fingers, that's how loose it was. The other one wasn't much tighter. Does that sound right? I know 6-8 ft/lbs of torque per the manual isn't very much, but I don't see how there was a good seal between the header and the exhaust port at that level of tightness. That's just it, maybe there wasn't and air was getting into the exhaust and affecting the O2 reading. The front nuts seemed a little tighter, but came off quite easy as well. I tried using a torque wrench when I tightened the nuts back down w/the new gaskets, but I'm not sure how well that worked, since I had to use extensions to get to the nuts and I was not able to get a socket on one of them on the rear and had to tighten it w/a wrench. At this point it is pushing 7PM and there's not much daylight remaining. I buttoned everything up well enough for a test ride, no rear fairing, and reset the AFV to 100 prior to starting the bike. It fired right up, but was idling really low. After a couple minutes, I held the throttle so that it would stay around 1K rpm. After it got warmed up good, I disconnected ecmspy and headed out. The bike ran pretty well. I noticed no popping at all when decelerating; it had done a little of that before changing the gaskets. I rode the bike almost exclusively in closed loop mode and did about 10-12 miles altogether. I had to say that it ran good. I'm a little afraid to get my hopes up, but I am hopeful that this may have improved the way it runs. If nothing else, I have eliminated the exhaust gasket question. Here are the new or quite recent parts that have been replaced that could cause these issues: -new tps and intake seals 5 months ago -new battery 2 months ago -new o2 sensor 3 weeks ago -new exhaust gaskets today If the issues continue to any significant degree, the next logical part to replace is the ets. As you can see in the picture above, the insulation on the ets wire is damaged and could be part of the issue. When I put it back on the bike today, I made sure that side of the wire was facing away from the engine and also routed the wire in front of the spark plug wire so it would be farther away from the engine. I figure it couldn't hurt and could only possibly benefit the sensor readings. Tomorrow I will have time to take it out for a longer ride and get the thing soaked w/heat. I'm sure I'll be back here with a report of some kind. I just hope it's good.  | ||

Two_seasons |

OK, I'm not giving up on you or this thread! I just got ECMspy today and was reading alot of info. Both in ECMspy and the Buell FSM they mention that a leaky header gasket CAN cause a lean condition, causing your O2 sensor to tell the ECM to send more fuel, hence the bucking and the popping. If I were you, I'd print off this entire thread, each posting, and make a list of all of the suggestions. Then tick them off, one by one as you have or will do them, until you have check marks next to each suggestion. Hope the exhaust gaskets (and it's usually the rear cylinder as it runs hotter---but replace both please) does the trick for you. UStorque---noticed you did not replace the exhaust gaskets on your former XB! | ||

Alfau |

Does that sound right? Header nuts very loose. You need to be very careful because these bolts are prone to come loose or snap off and leave you with even more grey hair from worrying. (hope you can see the light hearted side of this comment) Some examples:- http://www.badweatherbikers.com/buell/messages/327 77/286590.html#POST912979 For any parts you might need, American Sport Bike have a great attitude. | ||

Bikerrides |

Well, I did everything/the FSM except possibly the torque settings; I think using an extension changes things and I was basically guessing. I didn't just wrench them down as tight as possible. I tightened down the muffler mounts first/the FSM. Don't know if it matters or not, but I tightened the rear first. Before tightening, I moved the header back and forth until I could feel that it was centered in the opening and/or gasket. I assume the torque setting has something to do with breakage of the studs as well as the order the header and muffler are tightened in. I never got an answer to my question about how loose the nuts felt. How out of spec would that be? I was expecting them to be really tight, but according to the FSM, spec is 6-8 ft/lbs. I don't really have a point of reference due to inexperience. I tightened them until I felt like the header was seated in the gasket and then gave it just a little more. | ||

Ustorque |

Two_seasons: I had forgotten that step, I had replaced headeer gaskets on the XB also during my ordeal at the suggestion of one of the EBR techs during my search. It's a tough road he is on, luckily he's got some of the most knowledgable buell owners in the world to help. I want to see this turn out well! In my case My XB had something flakey somewhere that just didn't want to be found, and after 2 riding seasons passing me by it was time to move on. Perhaps it was fate, cause the tuber really speaks to me. Stacey, Do you have access to another ECM to try? Just for the hell of it or has that option already been exhausted? Keep up the fight! | ||

Ratbuell |

I'm trying to understand your exhaust process...you tightened the muffler first, then the header? I think that's a recipe for a cracked header...I always follow exhaust flow. Everything on, but loose, then tighten the heads first (rear first), then collector mount, then muffler clamp, then rear muffler hangar, giving the remaining pieces a good couple of wiggles between every step to make sure its all centered and not crooked. | ||

Buellistic |

EXHAUST INSTALLATION Class 101, just PM me of a copy ... Have a 111,208.6 miles as of the last rude and have never broken an OEM exhaust header stud !!! | ||

Bikerrides |

Hmmm....just rechecked the FSM and it says to tighten the header first, then the muffler. I could've sworn it said to tighten the muffler first, which seemed counter-intuitive to me. I'm going to loosen and re-tighten everything in the correct order before I test ride this afternoon. All I need right now is a cracked header or broken exhaust stud.  I feel kinda stupid, but I'm glad I posted the procedure I used and someone caught it; thanks LaFayette! | ||

Bikerrides |

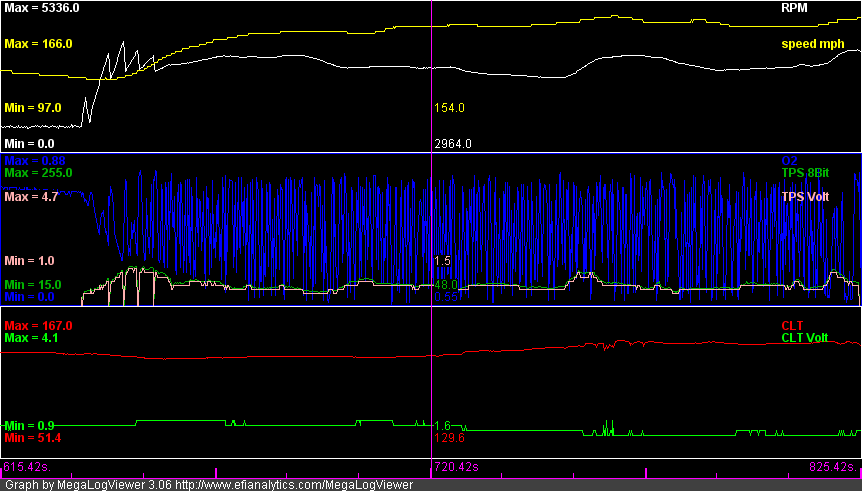

OK, here's an update. First thing I did today was loosen all the header/muffler nuts and bolts and then retighten them beginning w/the rear cylinder, then the front, then the front muffler clamp, then the rear muffler clamp. Here are some pictures of the exhaust ports after disconnecting and removing the header yesterday. This is the rear cylinder:  This is the front:  Rear w/header completely removed (I had scraped the gasket w/a knife):  Front w/header completely removed:  Anyone have an opinion as to the condition of the old gaskets? After reattaching the header and muffler I went on about a 20 mile ride that I was able to datalog using ecmspy. Here are a few screenshots from MLV that likely indicate that I don't have a ETS issue. The graphs show relatively linear movement in voltage and engine temp. I was able to compress the screenshot to represent roughly 3 minutes of run-time. Note: CLT is engine temp/sensor. This shot shows when I'm sitting at a light just before entering the freeway:  I assume the O2 should look like that when the DDFI is in closed loop mode. This shot shows when the rpm went over 3700 and the DDFI crossed into open loop.  I'm curious about the speed readings; 97 while sitting still and 166 max.  Do I need to change a setting in ecmspy or MLV or do I potentially have a speed sensor issue? Do I need to change a setting in ecmspy or MLV or do I potentially have a speed sensor issue? After running some 12-15 miles mostly in closed loop mode, it was time to do some hard accelerations, WOT, etc. This shows a few WOT shots:  This one shows several hard accelerations in and out of closed loop/open loop:  My question is do any of these graphs show anything abnormal? After getting back home and taking a look at this, I felt like I had made some progress. The bike ran quite well and the datalogging doesn't appear to reveal anything out of the ordinary at least to my very inexperienced eyes. Are there other data that I need to look at on the graph that might tell me more? So, I decided to go back out for another ride just to get some more miles in on the new header gaskets; no datalogging this time. Hmmm...the bike didn't seem to run quite as well. I noticed some skips at steady throttle that I didn't notice while datalogging. Then I began to notice a rather pronounced vibration that would start around 3K rpm and go away above 3600. This has never happened before; the bike has always been very, very smooth from 3K up. On my second ride today, it was smoothest at 2800 rpm.  What gives? What gives? | ||

Dannybuell |

did you retorque the headers after your first cool down? |