| Author | Message | ||

Hybridmomentspass |

the little brace that goes from motor mount/swingarm block and then goes to the motor, says 'buell' on it, triangular Do those nuts and bolts need to be torqued or just tightened? I couldnt find the item in my service manual appreciate any information on this hoping to do this one tonight, slowly getting things crossed off the 'to-do' list, hoping to fire it up by Sunday....  | ||

Jramsey |

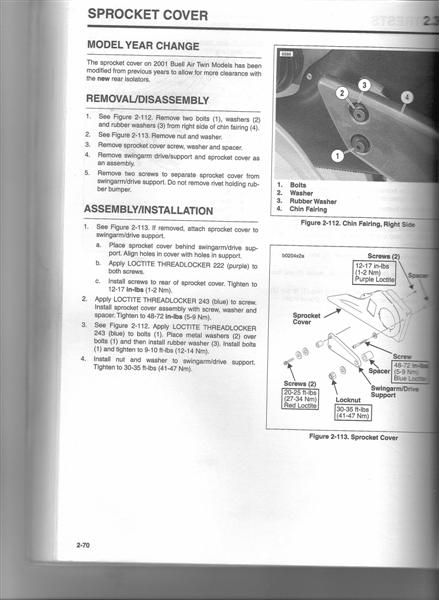

FSM shows 20-25 for the 2 shcs and 30-35 on the lock nut. | ||

Jayvee |

Yeah, their torque-valued a lot 'lighter' than I wrenched'em down at first. | ||

Buellistic |

Be careful with TORQUE SPECIFICATIONS !!! You can feel when the torque is "WRONG" and you are over tightening ... BEWARE OF "TORQUE SPECIFICATIONS" WHERE "ALUMINUM THREADS" ARE CONCERNED !!! | ||

Jayvee |

No, not really, I can't. Lot of times I twist'em on way too tight. Doesn't feel "too tight" to me, and I'm pretty much a weakling. But when I check the book it says like 10 foot-pounds, and I'm thinking "that won't even keep the nut on" but I just 'blue'it up and trust the spec, because I can't tell. | ||

Greg_cifu |

No kidding. 25 ft/lbs on a 1/4-20 in an aluminum CASTING?!? I would NEVER go by that number, no matter what the manual says. The torque tables I'm seeing for steel-steel (a grade 5 bolt going into a nut) say 6 ft/lbs (76 in/lbs) and for aluminum it's 4 in/lbs (45 in/lbs). Is that a misprint in the manual? It has to be. | ||

Jramsey |

Sorry for the confusion,FSM typo. The diagram 2-113 shows 20-25 ft lbs. In the text #3 it states 9-10 ft lbs. BTW the shcs are 5/16".  |