| Author | Message | ||

Mbsween |

All right, I've having no luck with this particular task and am thinking about new heads. There's always room for an upgrade right? So to recap, engine mount broke while I was on the way to AMA Vintage Days. I ordered a NRHS mount and drill/extractor kit from Al, then bought a 2004 BMW R1150R. So the Buell sat for a bit. I started working on it a week or so ago, but am having no luck drilling the bolt out. The drill bit is new, I'm using an 18V Dewalt on high rpm. I tried using a hammer drill, but that bounced the bit around and I ended up with what looks like minor collateral damage. Here's a pick of where I'm at. What do you thing? Did I dull the bit with the hammer drill, if so can I get a replacement at a hardware store/Lowes/Home Depot? Also does it just take an f-ing long time to drill into this bolt? I've probably been at it 30 minutes or so  | ||

Sportyeric |

The bolt is somewhat hardened and will take a while. You should be starting with a very small bit for a pilot hole then going bigger and bigger, I think. | ||

The_mad_mick |

GET A 1/8 TUNGSTEN/CARBIDE DRILL BIT A NORMAL DRILL MOTOR, CENTER PUNCH AND A SNAP/ON SHORT EASY-OUT OR A SIMILAR PRODUCT FROM A REPUTABLE TOOL DEALER. CENTER PUNCH THE STUD , THEN SLOWLY DRILL THE STUD WITH THE 1/8 BIT, ABOUT 1/4" DEEP THEN PLACE THE EASY-OUT IN THE HOLE AND HIT IT WITH A HAMMER TILL IT LOCKS IN PLACE THEN TAKE A 1/2" (13MM) SOCKET 6" EXTENSION BAR AND RATCHET HANDLE , TURNING IT COUNTER CLOCK WISE ,AND HEY PRESTO OUT COMES THE STUD .IT TAKES ABOUT 10 MINUTES TOTAL, BUT BE CAREFUL DRILL STRAIGHT AND DON'T LET THE DRILL BIT GET TOO HOT | ||

46champ |

The harder the material the slower you turn the drill bit this bolt is really hard. The hammer drill probably ruined the bit unless you are really good at sharpening. A pilot hole is a must. (Message edited by 46champ on October 18, 2010) | ||

Mbsween |

Thanks for the info guys. I'll give her another go and let you know how it works out Matt | ||

X1_rider |

If you have access to a TIG, maybe welding a nut on the broken bit (through the nut hole, if the broken bit sticks out a little) would work. The positioning is not ideal but I know I've taken out quite a few broken bolts with my TIG. edit: If you try it, I suggest you remove the ECM, I always do when I weld directly on a vehicle, just to be safe. (Message edited by x1_rider on October 18, 2010) | ||

Buellistic |

How about using a REVERSE FLUTE DRILL ??? | ||

Sportyeric |

Once you get going, keep in mind that the bolt is in there with red locktite so some heat on the bolt would be good. | ||

Buellistic |

FRONT MOTOR MOUNT Class 101, if you want the "INFO", just PM me ... | ||

Preybird1 |

I would not use any easy out tools at all. I had 2 easy outs break in the head and they were mac brand tools. What a pita it is to get the easy out if it breaks. It took me 2 hours of grinding to get the bad one out. The best way i have found is the reverse drill bit option or the welding of a nut to the old material and just turning it out. Patience and drill slow and straight, Don't try and drill fast just go slow and use mild pressure or you will just burn the bit and it will not do its job. | ||

Mbsween |

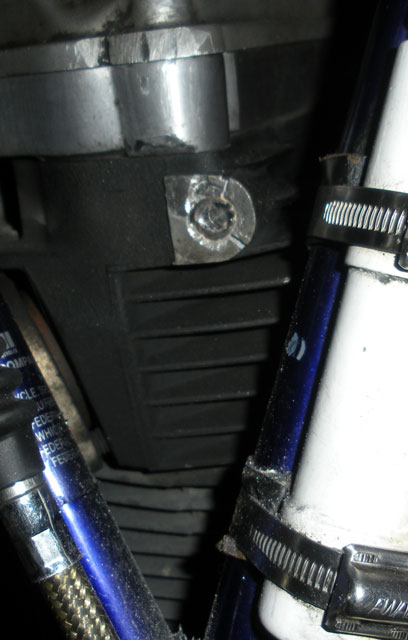

Thanks for all the good info, I got close but ended up with a cracking noise and well, let's just say it wasn't the bolt letting go.... Some things I learned. Titanium bits seemed to work better than cobalt bits. The drill worked fine with the slow speed. The pilot method really helps Patience....Patience.....patience, this take awhile. So I was thrilled when I got the hole deep enough for the extractor I got from Al (American Sport Bike). I must have been wiggling the drill as the hole I drilled was the correct bit for the extractor, but the extractor wouldn't bite. I tried a different extract (Craftsman) and it all seemed to be going well, then there was a sharp release on the ratchet (it was only a 3/8 about 10" long) and well then I saw the cracks. View from the front  View from the side  So looks like I'll be buying a new head. Since I have the NRHS mount for the thunderstorm head. I'll just replace with a stock one. Any recommendations on where to buy? | ||

Buellistic |

REVERSE FLUTE DRILL !!! | ||

Terrycoxusa |

sometimes you can get a small grinder bit and grind the bolt almost all the way out to the threads,after you drill a pilot hole, and then try an ez out, or carefully grind all the way to the threads and clean it up with a tap. Has anyone drilled out the whole thing and put in a heli coil? | ||

Scott_in_nh |

Umm, look closer guys, he cracked the boss on the head. Getting the stud out is no longer the only problem. Yes the head has to now come off, but from everything I've seen here, it can be welded up and machined as good as new for a lot fewer $$ than a new head - just saying... | ||

Reepicheep |

Bummer. Looks like you had the hole off to one side, and it was unfortunately the less supported side... though perhaps it wouldn't have mattered. Centering that hole is really hard, and recentering it after things go wrong is next to impossible. | ||

5liter |

That looks familiar. Same thing occurred here. New head installed along with the NRHS mount. | ||

Mbsween |

5liter, Wish I didn't join the club, but now that I have I was wondering what you did with rear cylinder when this happened to you. How many miles did you have on the bike? (I have around 45k) Did you have the rear head "renewed" (for lack of a better term ) or did you just bolt the new head on and go from there? | ||

5liter |

I didn't do anything to the rear head. I had about 49,000 on it when it happened. I thought I had the drill hole centered on mine and it was backing out just fine and then...........  Franklin fix! Franklin fix! | ||

Mbsween |

Yeah, I hear you I was extremely excited when the drill started working and was ecstatic when the bolt "broke" loose. Then reality intruded on my party....... I'm probably going to do a 1250 kit and new heads, cuz the head gasket and base gaskets are leaking and you know they need fixing and since I'm in there ........ | ||

5liter |

My front base gasket was starting to weep, so I guess the bike was telling me to fix the base gasket.  It didn't tell me to put in a 1250 kit. It didn't tell me to put in a 1250 kit.  | ||

Buellbozo |

Any machine shop with a ram type EDM can burn that bolt out so sweet, there'll be s little curly cue of material left in the threads that you can pull out with needle nose and save as "art". Weld the crack, tap the thread, and roll on. |