| Author | Message | ||

Buellisticx1 |

Hello all, Just finished to putting it back together Today and I start the bike and all worked fine (1250 Kit and porting Heads Stage 1 from NRHS, and Bronze Oil Pump Drive Gear). Except I'm getting oil leaks at the pushrods bases. I put some blue Jeams seals in using the NHRS billet base's. I realized when I'm tightening the screws of bases, the seals pinch and roll out and I cannot to be able to keeping the seals under the bases. I don't know if this is normal or no?, Any ideas what may be causing this or how to fix it?... I don't know how to fix it seals under the covers, any recommendations?... Thanks in advance. (Message edited by buellisticx1 on June 21, 2009) | ||

Guell |

Superglue the seals in spot with the bases, and then bolt it down | ||

Oldog |

had the same crap happen with the oe junk, I guess it works with the billet, parts, the pot metal ones should not be glued they leaked like a sive on the stock parts check to see if they are flat or straight, I bent one when it slipped off of the dowell pin and I missed it and torqued it in. it bent the corner up and the rubber part did not fit doing what was described above (squeezeing out) just another delay and another problem...... | ||

Skntpig |

I had the same problem with my NHRS bases. I preoiled the inside and the side that mated with the base. This let them slide too much. The fix for me was to clean the seals and bases very well. Then just lube the tube and a very small bit on the inside of the base. This way they held strong on the outside that touched the NHRS part. I used the seals that came with them. Good luck | ||

Kyrocket |

Instead of super glue I used the 3M 800 adhesive that I used to glue the cases together and let them sit overnight. I also reused my old gaskets since they were in good shape and the new ones looked like they might cause me trouble. I installed the black push rod tubes on NRHS billet bases and so far no leaks.  | ||

Preybird1 |

Those NRHS billet bases are sweet but bastards to install. The next time i have a problem, I am switching to the zippers collapsible push rod tube kit | ||

Dfbutler |

I had the same problem. The real bitch is that you have to put the whole thing together to find out it still leaks. It could be that the stage II heads require slightly shorter push rods meaning that the tube angles are different? | ||

Buellisticx1 |

Thanks for listening and suggesting folks!. I going to try what said Skntpig, lube the tube and a very small bit on the inside of the base for let them slide on the outside that touch the NHRS base's. I would not like back to pull the Rocker Box off again. Dfbutler, I also installed 040 shorter push rods than stock. Dan from NRHS recommended to me for Stage 1 Headwork. Regards. (Message edited by buellisticx1 on June 22, 2009) | ||

Dfbutler |

superglue the seals into the bases, lightly lube the tubes and slide them into the bases. It took multiple tries to get it right | ||

Skntpig |

No wait...Don't lube where the outside of the seal where it touches the bases. Just where the tube touches the seal or ID. I also did the same on the inside of the top ring gasket where it touches the tube. I used motor oil | ||

Kyrocket |

Lube them up good! I used Lucas assembly lube and put a ring around the flared part of the tube and also greased the inner part of the gasket and they were still a PAIN to push through. I first read it on here to push them through and I thought someone was on the hard drugs but they will push through with enough force. The problem lies, after struggling with them, your hands get all lubed up too and makes it hard to pull. Then once you get the first one through you have to take care and not bump it trying to get the second one through. I feel your pain, but it can be done. Good luck. | ||

Pkforbes87 |

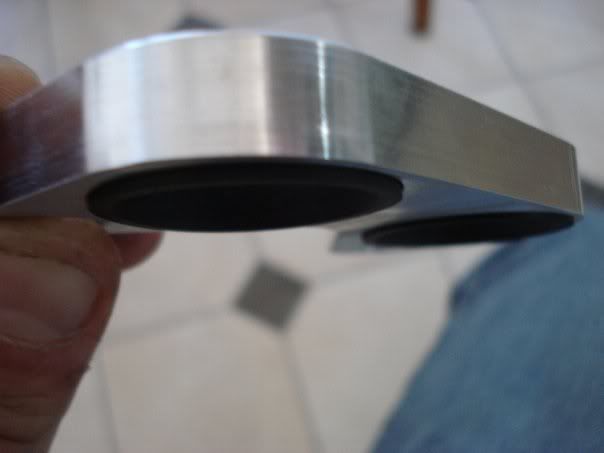

Step 1: take pictures of chrome parts, billet parts, and new gaskets  Step 2: superglue gaskets into bases  Step 3: lube the covers and gaskets to make them slide as easily as possible - I stuck the covers in the freezer but don't think it helped at all  Step 4: push base over the cover while cursing profusely. take an occasional break to throw something  The End.  If you're installing one one piece billet bases, pull the alignment dowels out of your case before you are ready to assembly everything. | ||

Buellisticx1 |

Thanks everybody, your input is PRICELESS. I appreciate it very much!. Will try do so. Pkforbes87, very good explanation along with pics. Thank you for your help, it is much appreciated. | ||

Skntpig |

Wow, Pretty sweet PK took his bike apart to show you. Seriously, nice pics. | ||

Pkforbes87 |

"Instead of super glue I used the 3M 800 adhesive that I used to glue the cases together and let them sit overnight." If that 3M adhesive dries slowly, then it might be the way to go. When I used superglue it was drying pretty much the instant I got the gaskets into the base. If you look close at the bottom pic in my last post, you'll see some ripples in the right gasket. Those are because the glue dried so fast and I didn't have time to flush up all the edges. They don't leak but they may start tomorrow. I'd rather have used slower drying glue and have a little extra peace of mind. | ||

Kyrocket |

I only used it because I had a whole tube of it handy and it gives a little. It's basically an industrial version of RTV silicone sealant. I had to go to Fastenal to order it. It's worked so far. If I had a way of sending it I'd share with everyone but it'd be dry by the time it got there. | ||

Buellisticx1 |

One question more please! Does anyone know if I could super glue the seals into the base without I got to pull the rocker box off. Have you ever had this happened?. The work of my new project is lasting a long time, about two months all weekends trough my bike and my wife is starting to grumble, I am causing them losing a lot of time all weekends (wife and son 5 years old). I'm anxious to get my bike running again. | ||

Kyrocket |

I'm afraid you're going to have to pull the rocker boxes and the heads. Is it on both cylinders or just the one? | ||

Preybird1 |

Ah the leaky base re-do Ive been here, Welcome to the BS  | ||

Preybird1 |

If you are really not wanting to go in again and can afford $250 you can cut the tubes and push rods out and do the telescoping push rod and tube conversion and then you can take them on and off with the rockers still on and untouched! http://www.zippersperformance.com/catalogue/showpr oduct.asp?cat=853&prod=1904 | ||

Brinnutz |

I've seen it done with the heads still attached...No leaks either. | ||

Pkforbes87 |

There's no reason to remove the heads.. Pushrod tubes slip into the holes in the heads, then slide the bases over the top of the lifters. | ||

Olbolt |

Here's my variation...OE bases, just slightly chamfered (by hand with a 82 deg. countersink) for a very slight lead on the holes for the dowel pins. This left a chamfer witness band approx 0.020 wide. Scotchbrighted the seal bores of the OE bases Superglued the new OE gaskets into the old bases w/ 8 drops each. 'C' clamped the bases with the gaskets to a block of aluminum to hold the gaskets in place while the superglue dried. Lubed the tubes with oil and slipped the base sub assy over - almost to the seated position. Inserted the oiled upper end of the tube into new 'o' ring in the head, then slid the base close to position over the dowel. Using 2 SQUARE SIDED screwdrivers together with the blades under a cylinder fin eased the base down square to the case. The retaining bolt was used for radial alignment mostly during the initial positioning. The screwdriver and the retaining bolt working together pulled the base down square. This scheme worked successfully...without leaks. ps: I tried the same thing without the chamfer and was unsuccessful in getting the base square with the case. } | ||

Buellisticx1 |

Well, I'm here again. Today I removed the rocker boxes again and followed step by step what said above Pkforbes87 for the seals install. I went for a test ride and when I get home I noticed a leak on front intake base, but not at idle, only when going on up 2500 rpm. The rear base is Ok, no leaks, but there were a great leak on front intake base. what am I doing wrong?....What should I do?. It's puzzling!!. This is starting to giving me headache. Any hints or tips would be gratefully appreciated!. (Message edited by buellisticx1 on June 26, 2009) | ||

Loki |

Lessons learned the hard way with these bases. Then relearned recently. Use the super glue trick. | ||

Buellisticx1 |

I glued the gaskets/seals (with super glue Loctite) into bases before to assemble, then lightly I lubricate the tubes and slide them into the bases. I thought that way they won't roll when put them on. I do not understand why it's still leaked. So I am now confused.. | ||

Pkforbes87 |

Does it look like the back of the bases aren't seating against the engine case all the way? Just wondering because that's what mine looked like. I don't remember what the manual recommends for torque here but I went quite a bit tighter just to get the base to finally seat evenly. Haven't had any leaks with almost 3500 miles since the rebuild. | ||

Eboos |

What I did with a problematic oe base and seal is spray them and the push rod tube down with brake and parts cleaner. This allowed the seal to stay in place much better instead of slipping out like it did with lube. No leaks. | ||

Buellisticx1 |

Many thanks for your interest to help me. Maybe the back of the bases aren't seating against the engine case all the way. I used a allen wrench but as you said I went quite a bit tighter just to get the base to finally seat evenly. I going to unscrew the bolts and try to pull up the bases to put some RTV silicone sealant around the case holes. Let's see how it go. Eboos, I will take into account your trick I will post the results...... | ||

Buellisticx1 |

Here again! RTV silicone sealant did not solve anything, I have not been able to fix. When I pulled up the front billet base I noticed that the half seal of the front exhaust was out from the back of the base, seems it rolled when I put them on. Half seal was unstuck from the base and bent, for this reason leaking oil. I will have to remove the rocker box for the third time super glue the seals into the bases again, and then bolt it down. This is starting to giving me headache. BTW as regards my X1 with 1250 kit and Stage 1 headwork from NRHS is AWESOME! I doing the break in period by now, but feel a solid increase in horsepower and torque, the throttle response is fine and more linear through the range, VERY smoother. I hope to fix the problem with the seal of billet bases soon and I can to finish the break in. I really want to know how the bike runs at all throttle positions. (Message edited by buellisticx1 on June 28, 2009) |