| Author | Message | ||

Bluesboy |

I replaced my primary shoe ass. and wondered which way the oil seal for shifter goes.I didnt check mine and numbnutz`s is M.I.A.,he has Banke,so I dont know? | ||

Buellistic |

It goes in to where the INSIDE PRESSURE causes the seal to tighten on the shaft ... If the plastic on the adjusting shoe had deep chain groves, it is telling you that the primary chain HAS BEEN or IS BEING adjusted TOO TIGHT(Factory Service Manual is WRONG) which should have been adjusted to 3/4" inch on the primary chain TIGHT SPOT ... The proper TORQUE(with anti-size compound on threads) sequence for the primary cover is a spiral(like done on a car head)from the center out length wise, first 2 ft. lbs., then 4 ft. lbs., finishing with 6 ft. lbs. ... The Factory Service Manual is again WRONG for properly installing the PRIMARY COVER ... If not done correctly it will weep(do not care how good a GASKET you install) or just plain leak, PLUS distort the COVER .. | ||

Bluesboy |

GEEZ I`ve not seen any of this info before! Any body know different? | ||

Buellistic |

REMEMBER THIS: The Factory Service Manual was written for technicians by technicians and proof read by technicians ... | ||

Jos51700 |

And THIS technician has used FSM's for a DECADE with none of the ill effects you describe. #1. The primary shoe will get grooves cut into until the rollers in the chain make contact. Then the sideplates stop cutting and tensioner wear stops. That's the way it works, and it works fine. It has absolutely NOTHING to do with the chain being run too tight. THINK: If you run a rear chain on a Japbike too loose, what happens? That's right. Your sprockets wear out prematurely. Same thing will happen with your primary sprockets, except that's an extremely expensive proposition. Been there, and seen that, and it happened exactly for that reason. And I'll take nylon bits running loose in a transmission and floating out with the oil over steel bits running loose and building up on the magnets in my flywheel, any day. 2.Although stepping-up on torque never hurt anybody, I didn't step up torque pattern on the thousands of primary covers I've R+R'd over the years (and many of those are HD big-Twins, which should be way more prone to warpage than a Buell/XL, what with being another 5 inches longer and bolting to another flimsy cover instead of a nice solid engine case) but I have YET to have ANY of mine come back with leakage issues. The antiseize on the bolts? Personally, I don't do it, and have yet to break an OE screw off due to seizure. However, Buellistic lives in Florida, and saltwater's a bitch. I can't say I would fault him for doing that down there. It's simply unnecessary here in Missouri. As a guy that's serviced more Buell's and 100K (Mileage, not dollars) HD's than I can remember, I must say that the dead-stock engineering of these machines is better than most 'Net posters would lead you to believe. | ||

Jos51700 |

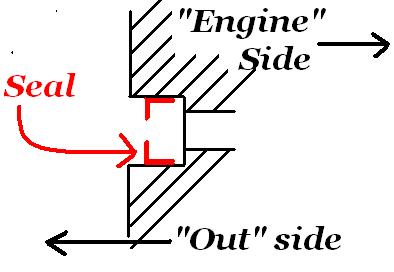

On the seal, the flat side goes out, the dished side goes in. Wrap the splines with masking or electrical tape, so they don't cut your new shifter shaft seal on installation. A 9/16" deepwell socket should fit well to drive it home.  (Message edited by jos51700 on October 27, 2008) | ||

Bluesboy |

Thank you! | ||

Buellistic |

BUELLers: How many of you'll have had to replace the ROTOR/STATOR/VLOTAGE REGULATOR because of metal getting into the STATOR/ROTOR,now if a DEALER just fix'es, but does not really tell you about metal and just takes you money ??? How many of you'll have had to replace the primary chain adjuster shoe because the primary chain is or was adjusted too tight which first causes the plastic in the transmission fluid before it gets to the metal for metal grit ??? How many for you'll have popped a $175.00 Drive Belt because the belt was or is being adjusted too tight ??? Have a 105,778.4 miles as of the last ride and none of these problems, Primary Chain 3/4" on the tight spot and Drive Belt 2" on tight spot ... How many of you'll have had to replace you speedometer sensor because of metal in the transmission fluid ??? With my proper maintenance, the plan is to go to 200K miles "PLUS" !! | ||

Numb_nutz |

HEY BLUE'S BOY I'M NOT M.I.A YET. I'LL SWING BY TONIGHT BEFORE YOU MESS IT UP AND GIVE YOU HAND. PS. HAVE BEER READY. |