| Author | Message | ||

Buellisticx1 |

From some time ago when i go in first gear and rev up engine (around 6K red line) and from 1st-to-2nd shift, don't engage at all, and just false neutral, the bike seems to jump out, and I have to give a strong kick to shifter, finally got it into. This just happening from time to time and not every time and only from 1st-to-2nd shift. Has had anyone similar problems? ANY IDEAS WILL BE GREATLY APPRECIATED | ||

Ratbuell |

Check your primary fluid level. If it's overfull, you have a leak from your engine oil into the primary. Had that happen on my FLHP once, HORRIBLE shifting until I replaced the seal (it's behind the stator). Either that, or could be a bent shift fork, or as simple as misadjusted clutch... | ||

Djkaplan |

Try the easy stuff first, but I had that exact problem and had to go in deep. I replaced the countershaft gears that have the engagement dogs for the 1st to 2nd shift and it fixed it. The dogs didn't look that bad, but the sliding gear was pretty wobbly on the splined countershaft. It cost less than $100 for the gears. Definitely do a shift pawl adjustment before you go that far, check the easy stuff, but that's what fixed mine. | ||

Buellistic |

It is very easy to adjust the primary chain to 3/4 inch on the chain tight spot ... | ||

Sloppy |

Very common -- worn shifter dogs, drum or detent plate is cocked. One of the weakest links in the Buell bike. Open the transmission and replace with Baker shift drum kit or go for a 5-sp. Baker tranny kit. I've rebuilt my tranny 3 times but I finally saved for the Baker tranny kit and I LOVE the way it shifts. Shifts like my dirt bikes now! | ||

Buellisticx1 |

Thank you all for input. I have checked the primary fluid level today and it’s right, the oil comes up to the bottom edge of the SPRING,diaphragm, the Crank seal is good, no problems so far, (45.000 miles on it) I know going to have to remove the entire primary drive for checking, but I have some doubts that I would like clear up: 1.- will need to remove/disassemble the individual clutch parts? Or just the clutch basket and plate assembly as a whole?....,if so,will I have compress that clutch spring prior to taking the snap ring out 2.- Can anyone give me a handy tip to remove/disassemble the clutch basket and plate assembly please……… 3.-will I can take off the Engine Sprocket nut with a Torque wrench or will have to use a gun impact?...any experience?.... 4.- should I take into account something? P.S. Hey Sloppy What is a Baker shift drum kit?... can you post any pics? or some link where could I get it? Thanks in advance. (Message edited by buellisticx1 on September 20, 2008) (Message edited by buellisticx1 on September 20, 2008) | ||

Pkforbes87 |

Hey Sloppy What is a Baker shift drum kit?... can you post any pics? or some link where could I get it?" I got a baker smooth shift kit for my X1 a few months ago. It's a redesigned shift drum + detent plate. Shifting seems a little smoother. I think it cost around $300. If a new shift drum will fix your problem then this is a great fix plus an upgrade, but I don't think I would have spent the money just for a small improvement. American Sport Bike has the smooth shift kits. Ask Al about filing down the hex head on the detent plate. You'll need to do that to avoid slight interference while shifting 3rd->4th. I had a dealer install mine (STUPID) and they didn't file the hex head after being told 3 seperate times. Now I can't speed shift 3->4. | ||

Jos51700 |

If you're removing ANY fastener with a torque wrench, you shouldn't be working on it.... | ||

Kalali |

"If you're removing ANY fastener with a torque wrench, you shouldn't be working on it...." Could you please explain why? I assume he is saying this because most torque wrenches provide much better leverage due to longer arm.... Will it mess up the torque wrench's accuracy or there is another reason? | ||

Pkforbes87 |

yes, you can fubar the calibration on the torque wrench by using it to remove anything tight. get a breaker bar, and a 3 or 4 foot pipe that will just barely slider over the breaker bar. I never have problems breaking things loose  (or breaking sockets) | ||

Sloppy |

Baker shift kit -- Google Baker Drivetrain. They can also build you a new tranny for you which will end all your tranny issues, but you do have to pay, but I think it's a good value. The problem, IMHO, is the Buell tranny was designed for ~ 75 hp cruising Sportster, while the 101 hp sport Buell is ridden more aggresively, hence the frequent issues with their transmissions. Baker Drivetrain has a significant number of design changes such as stiffer bearing supports, ramped gear dogs and a solid detent plate which make it the "correct" tranny for the Buell. First you need to get the Factory Service Manual (FSM), invest in a variety of tools as outlined in the FSM then get to work. If you know how to rebuild a brake caliper or master cylinder then you'll have enough experience to remove the tranny. If you're not comfortable with this then send it to someone who does know -- or prepare to make the tool and time investment in yourself. You do not need to disassemble the clutch, only remove it as an entire assembly. There's plenty of details in the KV so you don't have to reinvent the wheel on this. And if a Journeyman saw you use a torque wrench as a breaker bar he'd toss you out of the shop. WARNING -- not all torque wrenches are designed to be used in both a CW or CCW direction. Read the spec's to make sure! BTW, Craftsman will lifetime replace a breakerbar but NOT a torque wrench... | ||

Buellisticx1 |

Thanks guys! I really appreciate the info.. Just a question more: have I compress that clutch spring prior to taking the snap ring out. Thanks so much again. | ||

Djkaplan |

No... not to get the clutch assembly off the input shaft. | ||

Jos51700 |

Pull out the very center snap ring, and then remove the adjuster assembly, and then use a BREAKER bar (Breaker bars are for breaking loose, torque wrench's are for torquing up), on the LEFT HAND THREAD nut you'll find underneath. You'll need to "block" the rotation of the primary assembly some way. And you did disconnect the battery, right? No 3-fingered Badwebber's, please. I've been nearly thrown out for using a torque wrench as a breaker bar, until the shop foreman realized it was an old gutted breaker bar, welded up solid. | ||

Buellisticx1 |

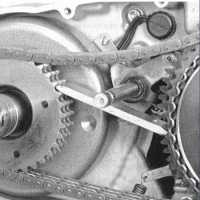

You'll need to "block" the rotation of the primary assembly some way. With this tool(Primary Locking bar Right?  I have this Torque wrench (22" long)and it's designed to be used in both a Clockwise and counterclockwise direction. Do you think that I could using for breaking loose the crank nut?  Many thanks.}} (Message edited by buellisticx1 on September 22, 2008) |