| Author | Message | ||

Road_thing |

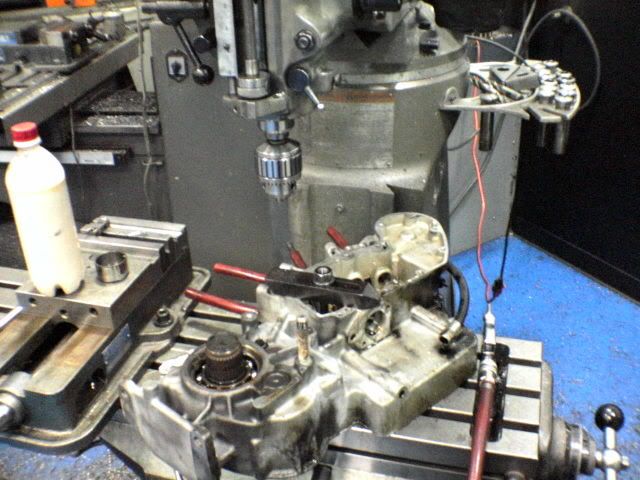

Never mind how I did it--how do I fix it? Can I get that crack welded up without splitting the cases? rt | ||

Oldog |

RT it looks far enough aft to be in the primary / gear box area ( unless I got it back wards, ) the big thing is to get the break as clean as possible, drain the oil and flush the case with solvent if possible, contact a local Heliarc guy and have him look at it he may want to vee it out a little and you will likely will lay the bike over for the job. One last question, can you clean it up and put JB weld or similar on it ? | ||

Wile_ecoyote |

I second the JB weld, try it first. Use spray brake cleaner and rough the surface up with a grinding wheel or the like. Spray down so no oil is present then epoxy or JB it. Dont need much, just nuff to fill the roughed up area. Done it several times with great success for myself and price concieous customers with dirt bikes and quads. Best of luck. Remember, if it dont stop or gets worse, then you can weld or replace. | ||

Mikej |

I'd want to know how it happened, impact, stress, torque, gunshot, Evil Knievel jump over an Armadillo in the road????? Knowing what happened to cause the issue will let you know if you have to get a look inside. Is the crack all there is or is there a big flake about to peel off inside? Also, is this in the tranny area making the inside peekable without case splitting? Or is this in a nastier area? Is it in a high stress area that might be an issue later on if not properly repaired? How about playing around with some infrared photography on the problem area, or look into an x-ray of some sort. Can you post a zoomed out pic to give a better idea of where we're looking at on the engine, or would that reveal what you don't want to reveal. Whatever happened, sorry, doesn't look like any fun at all. | ||

Reepicheep |

That alumiweld stuff works at a lot lower temperature then welding, just barely at the temperature where the aluminum starts to weld. Map gas is enough to do it. I don't know that i would recommend it... an engine case is a high stakes gamble, but to be honest it would probably work. I'd do it on the KLR though... but i would have to grind out the JB-Weld that is already plugging the hole today (and working fine, FWIW). | ||

Aaomy |

i have had no luck with the alumiweld,, everything i have tried with it it pulled off under load or pressure.. i played with some of the stick form puttys and jb weld before too.. although the stick form is often "stronger" it forms a weaker bond to surfaces and tends to pull away long before fracturing.. the jb weld on the other hand bonded excelently to al and actually fractured in two before peeling away form the aluminum.. of course that was with repeated hammer blows.. " gotta test this suff before you use it" for what i see i would say use the jb weld.. or take it to a profesional.. | ||

Jos51700 |

You shouldn't try to jack up bikes with bottle jacks under the engine cases. (just a guess)  Hopefully that's not a recall shock, and if it is, you were trying to jack it up to replace it.... (Message edited by jos51700 on February 04, 2008) | ||

Jos51700 |

A case that big should really be tig/heliarc's. Using gas heat will take forever due to the mass, fail to remove the oil from the break (giving a weak, nasty, leaky weld), and possibly weaken the metal (depending on heat treat). There are some very good machinist/welder types on here. You may try posting on a different page with more exposure. | ||

Road_thing |

Good guess, Jos51700! The bike was completely torn down and I was assembling the engine/swing arm. I had the front of the motor sitting on a stand, and I had jacked it up there with the little bottle jack. The bike slipped off the stand and came down on the ram of the bottle jack. Didn't seem like a real big hit at the time, but when I looked at it the following weekend, the was a LaBrea size pool of oil underneath, so I got out the flashlight and found the crack. Shoulda had a board or something in between the motor and the jack--I won't make that mistake again! Ain't it funny how the most expensive lessons are the ones that stick with you? Mikej--good point, I haven't really looked hard to determine whether it's motor oil or tranny oil, but I strongly suspect it's the former. Here's a slightly wider view--taken from the port side forward, looking aft--you can see the primary adjuster on the right.  rt Edit to add: Here's a link to a picture that shows how not to support the front of this assembly!} (Message edited by road_thing on February 04, 2008) | ||

Phat_j |

jbweld is definatly the key........ but 2 things to do first...... one.... make damn sure its clean.... lots and lots of brake clean...... two.... take a small drill bit.... and drill a hole at each end of the crack (this will stop the crack from spredding) this type of repair if done correctly will last many many years. | ||

Cyclonemduece |

well it is not a stress related crack so i dont think drilling holes is needed but like everyone else said jb should work grind into the aluminum a little bit to achieve better results post up ad let us know how it turns out blake | ||

Jramsey |

Just to let you guys know, most welders will charge twice the price if its been JB'd or epoxied first. I myself won't touch side cases unless they're off the the motor. Aluminum has to be virgin clean no oil,paint,gasket adhesive,etc. for tig. Been doing them for over 35 years. | ||

Joesbuell |

It's a shame Tom you didn't have this little gadget I made!  If it were me I'd have to pull it down and have it welded, As I'd be to paranoid that the oil will leak out damaging my engine/transmission or putting oil over my rear tyre, And we know what can happen then...Sorry to hear of your misfortune  | ||

Jramsey |

Joesbuell That dolly while useful doesn't work very well unless the muffler and shock are removed. | ||

Rocketman |

Thong, forget JB weld. It's a high street band-aid. http://www.devcon.com/ I use a couple of their Metal-Filled Epoxies when the shit hits the fan! It works. It ain't cheap, but it is the  real thing. And it's American made. real thing. And it's American made. Rocket | ||

Pammy |

Unfortunately RT I must agree with Jramsey. The good news is that it can be repaired. As good or better than new even. I haven't read the whole thread, and I am not familiar with the product that Rocket recommends, but my opinion would be split those cases. PLUS, there is some other neat stuff you can do whilst you are in there... Now you can always buy another motor and swap the top ends, but that is a bit of work as well and then the numbers don't match, etc... | ||

Jos51700 |

It's funny how seeing other people make that same mistake will stick with you. I've always had bike lifts which support the front end, so I've always used the bottlejack under the swingarm block. Judging by color and location, it's engine oil. I'll state my opinion this way. If you were buying this bike, and the seller told you what happened, would you want to find JB weld, or a heliarc repair? If it would affect your opinion buying the bike, it should affect your opinion repairing it. Where it's at is not particularly stressed that I know of. I would be surprised if it spreads. Now, what about that recall shock? | ||

Court |

Wisely spoken . . . herein lies the opportunity to snatch great things from the jaws of misfortune. PROJECT ! | ||

Road_thing |

Thanks, everybody. This one may have to sit for a while. I think pulling it apart is the right thing to do, but my plate is full to overflowing at present, I'm not sure I need another project! I'm in the middle of selling my house in Houston, moving to an apartment and building a new primary residence at the ranchito, all while attempting to find and produce all the $90 oil I can. Plus, I'm in charge of fundraising for a major oil & gas convention in Houston this fall, and I have the 25th annual geological society skeet shoot coming up in June (I've been chairing that one for the last 15 years or so). In my spare time, I thought I'd just bolt together a franken-bike S1 from a spare motor and a roller chassis I got from another BWB'er. Best-laid plans and all that... As one of my bosses told me many years ago, "That's why they put lights in those buildings--so you can work at night!" rt | ||

Rocketman |

Thanks, everybody. This one may have to sit for a while. I think pulling it apart is the right thing to do, but my plate is full to overflowing at present, I'm not sure I need another project! It would need only sit for 24 hours absolute max, and it will never leak once repaired with Devcon. Do yourself a favour Thing  Rocket | ||

Joesbuell |

"Joesbuell That dolly while useful doesn't work very well unless the muffler and shock are removed." The other thread that shows a picture of Road_things engine and rear end only needs the front mount removed and you can have the thing in a safe working position. Whilst I have been working on my Buell for the last year and a half I've had no close calls or damage to any part of my bike. For the sake of removing the shock and mount while you rebuild your bike I believe is worth the trouble! Hey but what do I know... | ||

Oldog |

hey Jody have you got a sketch of that stand with some measurements?, steel and welding equipment are available here at work cause that would be the shiznitz for the anual IRAN(s) | ||

Ratbuell |

I'd want to echo the earlier post - you never know if there's a piece of metal inside ready to flake off. Think of a bullet hole in glass - if it took enough of a shot to crack the outside, how big is the impact "crater" on the inside, and what does it look like? Same as the outside? Or a piece of burnt pepperoni, curling and ready to come off at the first extremely inopportune moment? | ||

Joesbuell |

Jim I'll try and measure it up as soon I can. | ||

Spiderman |

I may have missed this as I have just skimmed over the posts. But from the pics and my experiences in machine shops and with welders I would say drain the oil, ckean it up nice and good. Take out the battery and load her up in a truck or trailer. I would take the shock and muffler off too. Bring a matress with you and take to a local welder with a TOG tourch. Seeing as the crack is very small and loaclized I bet a really good welder could weld that crack back together with little or no filler rod. I had a welder weld back a broken rear mounting tab on MJ. Still there and kicken, remind me and I will show it to you at Homecoming.  if you look at the rear motor mount you can see the missing top tap... | ||

Spiderman |

oh and BTW that area of the case will hold motor oil... | ||

Aaomy |

love that picture spiderman,,, i understand road things idea about tearing as little apart as possible.. unfotunatlly the frame wouldn't clear the mill so ......  keep us posted on what you choose to do.. | ||

Pammy |

I looked at the Devcon website. It looks like a good product. Better than regular JB weld. It might be worth a try. Especially since you are short of time. If it doesn't work THEN we can do a dis-assembly and weld'er up. The problem with adding heat to a porous metal such as aluminum, any contaminate left in the case will be drawn to the site. It would be like painting over grease. | ||

Mikej |

"It would be like painting over grease." Spray it fast and thick with a good fan blowing a stiff breeze to get the surface to set up quick.  | ||

Mmmi_grad |

Do what rocket man says. That stuff will hold, just ruff up the area first to make an even better surface for the epoxy to bond to. Worse case senario take to weld shop. They might bitch about welding on the bike with gas tank on and whatever though. Actually they might not wana weld it complaining that oil will find its way out. Also you might get a welder worried the case isnt vented enough and therfor he would cause seals to blow. I know a little about this stuff. Bottomline....... this is a big gamble if it needs welded because poor guy is depending upon what kind of talent is in his area and if they are willing to do it. But if someone is willing and gets a good weld on that case it will be good as new. | ||

Road_thing |

Thanks, everybody! I've got plenty of time, no hurry to finish the project. I think I'll take a shot at the devcon repair. If it works, great--if not, well, the cost of the welding isn't the big issue, it's the labor to tear the motor down that hurts. The bike isn't together (see the link I posted above) so it wouldn't be a big deal to grind the devcon off and haul the motor to a welder if it doesn't hold oil. Wish me luck! rt |