| Author | Message | ||

Crowbar |

The start of my streetfighter.......   | ||

Koz5150 |

Interesting choice to Black out the PM rims. I have always been a fan of the flat black, road warrior look. I think I would consider painting the forks also. Looks good. | ||

Koz5150 |

Can you tell me a little about your muffler? Is it just a straight pipe or is there some baffling? | ||

Crowbar |

it is a straight pipe | ||

Crowbar |

yeah im planning on doing the forks black as well..during the winter though so i dont miss out on riding time | ||

Whodom |

Crowbar- Cool bike, but isn't that the old "recall" shock still on there? You should be able to get it updated for free. | ||

Crowbar |

no it is the new one...well thats what harley said | ||

Spiderman |

looks good, lets get a close up of the tail section and how ya mounted the brass knuks | ||

Koz5150 |

How has the straight pipe affected your performance and sound? (I am sure it is loud, but does it back fire or pop alot when decelerating? | ||

Spiderman |

I can't speak for his pipe an bike, but my straight pipe has a small dip at 1800 to 1900 rpm's and that's all, in total I make 95 HP and it sounds great! | ||

Crowbar |

ill take some close ups tomorrow in the day time... and i used a rivet gun to put the knuckles on... and then pipe sounds great ... it hasnt affected the ride at all .. I have a vance & hines pipe that i put on for inspections purposes... | ||

Koz5150 |

I think I will be making myself a pipe for special occasions... | ||

P0p0k0pf |

That's the "old recall" shock that was prone to leakage... The "new recall" shock is shorter, comes with a front bracket to compensate, and has a thicker rear eye. I think the "old recall" shock was only replaced under warranty or goodwill if it started leaking. The original shock had an exposed spring and was replaced as a safety recall I believe. | ||

Crowbar |

yeah my friend has the shock that your talking about...yeah my other buell shock started leaking and it is the same as this one | ||

Tod662 |

I just got my shock updated on my s1 last week just go to the dealer and give them the vin and see if the recall is still open | ||

Devdawg |

Koz, Gonna make the whole thing or just a slip on?? I might be interested if you're willing to make two... | ||

Koz5150 |

I currently have the new WileyCo which has the canister just slip onto the elbow. I am just going to make an attachment that replaces the canister with a straight pipe. It probably won't work on your bike. | ||

Spiderman |

I have ben thinkin about re-creating the KT, but i need a bender an a TIG welder LOL | ||

Smokedaddy |

Nope, you don't need a bender. You can buy pre-bent fittings and make any desired degreed fitting needed out of those you bought. If you do, don't be stupid and miter the pre-bent fittings but instead make a degreed fitting. Oh, you don't NEED a TIG welder either (but it would be nice). You can stick it, MIG, or even gas weld it (cheapest). You'll end up grinding it no matter what you use, so it makes no difference. -SD: | ||

Doum2 |

hey crowbar, How did you do the straight pipe did you have it made or purchase it? I'd like to do the same to mine. | ||

Crowbar |

i made it ... Ill double check the size pipe i used but it isnt that hard to make | ||

Spiderman |

Smoke, Yes you can buy pre bent but then that limits my creativity and ability to control flow. And about welding. If you can stick weld (I am presuming you are talking about Arc) then you are the man if you can do that with a metal so thin. Mig will work And TIG will leave welds so beautiful you will not need no stinking grinders and will leave a lot stronger weld. | ||

Smokedaddy |

That's SmokeDaddy, there is a Smoke here but not me. I was under the impression funds (greenbacks) were limited. Was just making a few suggestions IF that was the case. Oh, I am indeed the man when it comes to welding certain pipe or tubing processes. Course I'm getting older and the eyes aren't what they used to be. I have quite a few years of experience and cert(s) in semiconductor Orbital welding, some pipe Video Diametric machine processes, nuclear NarrowGroove GTA welding, SMAW, GTAW, MIG and a certain brazing processes. No problem welding anything thin (except sheet metal) with SMAW, if necessary, at least for me, select the proper rod, including a smaller diameter one, reduce the heat and step the rod. Been doing it for nearly 38 years now. Anything from schedule 5, 10, 20, 30, 40EH, 60, 80EH, 100, 120, 140, 160 and DBL EH pipe and different wall thicknesses of tubing. This includes semi-conductor grade electro-polished tubing from 1/4" to 6" to strict color and analytical spec(s) and pharmaceutical grade tubing to less stringent analytical spec(s). I've welded pipe as large as 120 inch diameter pipe and smaller pipe with wall thicknesses up to approximately 2 3/4" inches. If you haven't the funds to buy a bender, one can buy pre-bent bends and create anything if they have the ability and knowledge to do so. It doesn't limit ones creative abilities in the slightest. Not understanding how to create degreed fittings from pre-bent fittings of any desired angle does. I be Da'Man, -SD:  | ||

Oldog |

Thats Impressive! I'll bet you can weld, just about any thing. including sheetmetal one question what is "step the rod?" I have not seen sched 5, sched 10 is almost sheetmetal... | ||

Smokedaddy |

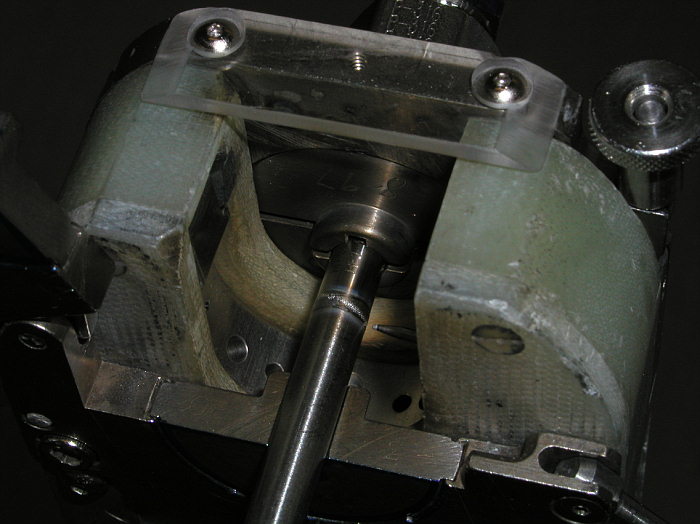

Yep, anything from a broken heart to the break of dawn. <grin> Stepping is done with 6010 and 6018 (different flux coating). You run hot, create the puddle for an instant, step out of the puddle (in front) and step back in 1/3 and fill, then repeat the process. It's sort of like stacking dimes but a little smaller. Actually I have welded just about everything but I'm not an expert at any one specific process and all filler rods but good enough to hold quite a few current cert(s), even though I'm retired. Oh, schedule 5 pipe, say in 4" nominal, has a 11/64" ths wall and schedule 10 is about 15/64" ths (prolly 7 and 4 gage). Actually pretty thick. Oh, forgot to mention the plastics too, hot air welding and butt-fusion welding (InfraRed) pipe, like PVDF, PFA, PP etc. Have to watch some of this stuff too from off-gassing of teflon ... called Teflon Fever or also called Polymer Fever. You can really really really get super sick real quick. 10,000psi socket weld 100% xray:  GF+ InfraRed 225mm butt-weld machine:  Orbital 206 machine (semi-conductor):  Narrow Groove diametric (for Paloverde Nuke certs):  TIG (clean room - hand weld - semi-conductor):  This will get you tuned up on your welding. A little pharmaceutical welding. Just a fraction of the piping that exist. (Baxter in CA.):   -SD: | ||

Smokedaddy |

Nothing like screwing up this thread ... -SD: <grin> | ||

Devdawg |

Koz, You're right it won't work on the bullett I'm running now...but I also have a Wileyco that I could bolt it up to....let me know how it works for you. | ||

Ceejay |

Wow smoke, you got skills, I work with swag a lot and that is some of the best welding I've seen, nice. A cross thread is a tight thread  | ||

Buellzebub |

nice beads! | ||

Oldog |

$#@%@#%$ WOW! Yeah I think you could build a header or 2 the last two pix, a big still right? titanium tube frame frames? dont know about cross thread but Def-in-ately you -da- man  Oh BTW I liked the scroll work on that arm on Aaomys' thread some of your handi work? |