| Author | Message | ||

Crusty |

Not all craftsmanship is dead. scroll down and watch the video http://www.rgmwatches.com/guilloche/ | ||

Aesquire |

Normally when I think of "engine turning" I think of the abrasive process used for making overlapping circles on metal, like the cowling of "The Spirit Of St. Louis". https://en.wikipedia.org/wiki/Engine_turning A wood dowel, or metal rod, is chucked in a drill press and the end dipped in abrasive, ( like valve grind compound ) the work touched and then moved, over and over until done. ( you also see machines that do this work on production parts ) The single point techniques used by RGM are the most refined "machine" engraving, until the coming of CNC machines. Which are cheating..  Love RGM watches ( not in my price range, alas ) and classic tech. Compare this to my Galaxy phone.... much more style. | ||

Strokizator |

Which is more beautiful, the watch dial or the machine that crafted it? Why didn't my high school guidance counselor mention guillocheur as an option? Previously, whenever I heard the term "engine turned", I always pictured the dash panel of a mid 70's Trans Am - which was probably faked. Some brass era antique cars had real engine turned dashes. | ||

Aesquire |

You only see the Guilloch method used on high priced items today. Skilled labor is expensive. Manual machine labor, as you see in the video, is not quite as skilled as hand engraving, but well over the level of "put the part in the machine and push a button". Which is also more expensive, and more skilled, than robotic manufacture. How you rate other labor intensive jobs can be subtle or obvious. A guy flipping burgers at McDonalds ( a job I have done ) is not at the skill level of a sous chef at Applebees, ( although it's not as big a jump as you'd think, it's a jump ). An old school lathe operator may have less school training than a CNC operator, but may be more skilled in hand work. RGM uses a LOT of old machinery from now defunct watchmakers to turn out a very high end production product. ( and, if you have the scratch, custom work rivaling anything from Europe ) a LOT of hand work... and a price tag to match. | ||

Aesquire |

Here's examples of the finish you get from the abrasive technique. Not "hard" to do, but requires patience, practice, and a tiny touch of artistic talent. ( And about the max level of "artistic" I am capable of. ) Simple drill press work. You can see how it could be done entirely by machine, if you wanted large quantities.... But it's real origin is covering up the flaws in hand hammered sheet metal by adding an eye distracting finish, as opposed to a polished surface. (Message edited by aesquire on August 29, 2015) | ||

86129squids |

"How you rate other labor intensive jobs can be subtle or obvious. A guy flipping burgers at McDonalds ( a job I have done ) is not at the skill level of a sous chef at Applebees, ( although it's not as big a jump as you'd think, it's a jump )." There are no chefs, or sous chefs at Applebee's. They're cooks. Most chefs don't "jump", they've been to a cooking school and graduated... some from the CIA.  Didja ever make it to Hamburger University? | ||

86129squids |

I always sucked at math... but, the sheer beauty of the guilloche (DANG, BW spelchuk didn't hit on THAT?!?!  ) was awesome. Thanks for sharing, Crusty. ) was awesome. Thanks for sharing, Crusty. The difference engine also intrigues me... that would have been part of the genesis of what Turing accomplished. Really fascinating work. My best friend is a skilled CNC machinist. I'll see to it that he knows about guilloche. Fun stuff! Hopefully I'll live long enuf to be able to afford one... the one in the vid that displayed "Carpe Diem" really struck me. If they could fire those words in silver over one of those black metal dials... PS- well, BW spelchuk DID hit on it, but not evidently, it never underlined it. DILLIGAF. | ||

Aesquire |

By jump I meant difference in skill levels. The Applebee's line needed a smiley. My Mom is addicted to cooking competition shows. No. I never made it to Hamburger U. I'm no chef. I don't even claim cook status. Machinist, yeah. I'd have no problems running that antique engraving machine. Take a few practice pieces to get the hang of it. It's really nice to see such old school work is still out there. The RGM founders have a clear vision of what they wanted. Bought and restored a bunch of machines from Hamilton and a few other now gone American watch companies. It's a niche, & upscale market. My house cost less than a tourbillion. | ||

Aesquire |

If you go to the "Touch of Modern" sale site, they do lots of watches between the tech toys ( iphone stands galore ) Japanese sex toys ( teledildonics! ) wall art and yuppie clothing. Antique watches are huge bucks. | ||

Bluzm2 |

I've done a bit of "engine turning". There is a bit of overlap in two terms. Engine Turning and Dimascusine. Both usually refer to the above pictures that Aesquire posted. I've done a bit of it on some Buell parts for a friend. On smaller pieces it's pretty simple of you make a jig to hold the part then use a cross vice on your drill press. I've done it with the abrasive rubber sticks you get from a auto detailing site (Eastwood Automotive is where I got mine), I've also use a dowel with a hard leather disc glues on and valve lapping abrasive compound. Both work well but the abrasive stick is faster and easier. One thing with the leather/dowel, you can use different compound for different effects and metal types. The one I've not yet tried is the brush method. They make metal brushes and holders of various widths you chuck in a drill press. The brushes are short stiff metal bristles of various metals. I'll try those one of these days.. | ||

86129squids |

Aesquire, yeah, we are into several cooking shows, many on our PBS3 "Create" channel. We love to cook at home- my sweetie is Dominican, and I'm OK as a home cook... things don't suck too bad in general. (Thinking REAL hard for tonite's dinner about attempting something resembling Carlos' pork loin he did on the grill at C3 for Glitchfest... a plate of THAT properly dressed could fetch $25-30 in any place I've worked!  ) ) As I'm into the high end of restaurant work as a server/bartender, I take every chance I have to talk up the quality and finesse of the plates I serve on behalf of the kitchen. The skill levels and techniques of a chef's brigade are both subtle and obvious, and DANG do they work hard! OTOH, metalworking, woodworking, glassblowing, et al, all fascinate me when I see true craftsmanship. In this modern era of 3D printing and such, I guess the artistry will boil down to the creativity of the programmer... or maybe it's just another means to very creative and imaginative ends. | ||

Aesquire |

Art, in it's many forms.... Does a cartoonist who uses pencils deserve any more credit than one who uses a computer? Most started with old school tools and moved on to more techno techniques, so I say... maybe not. You could do the Guilloche work with a cnc machine, and make it cheaper with far less labor. Somehow that does seem like cheating to me... Ultimately when we have Star Trek type replicators, all the art will be in the original creators hands. Intellectual property. One guy carves intricate scrimshaw on artificial ivory, and anyone can have it as soon as it's published. Or that filet of Mammoth with the incredible Lingonberry chutney the chef where you work came up with, will be devoured with glee in Shanghai. Yet I think there will always be a market for good hand work. Small in proportion to the entire planet, but RGM watches, A great pie, and Buggatti Veyrons will still get made no matter the available tech. I have no desire to own a million$$ car with no room to toss my tent, but I'm happy such things are made. I'll probably never get a RGM watch. Or buy an antique Rolex, but I've popped for a Citizen Ecodrive for dress occasions. Still wearing the beat up Timex when I go work on the tractor.... speaking of which. | ||

86129squids |

Just found this today, fun stuff! http://www.npr.org/sections/thesalt/2015/08/30/435 248291/how-fishermen-s-bragging-rights-gave-birth- to-fine-art And, more fun... http://www.npr.org/sections/thesalt/2015/08/26/434 958065/the-bloody-mary-meat-straw-an-all-american- story Sorry, no highjack intended. Please carry on. | ||

Aesquire |

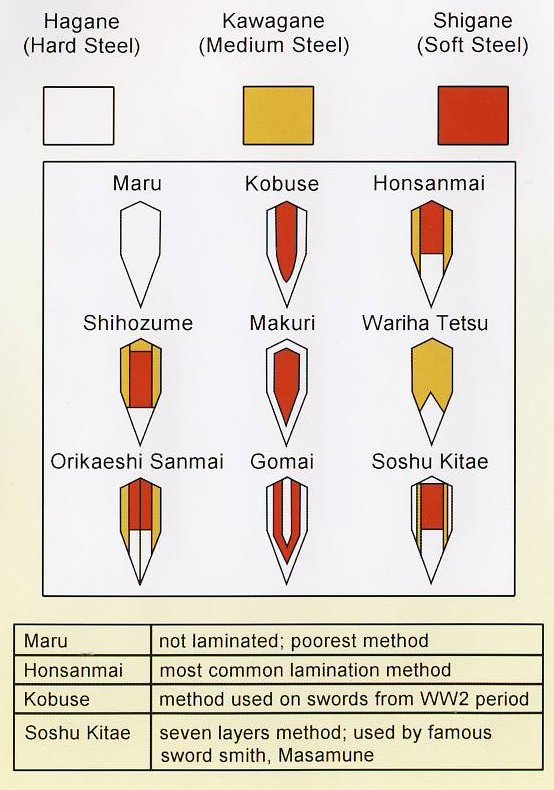

BluzM2, Dimascusine?? Folded steel work? https://en.wikipedia.org/wiki/Damascus_steel Interesting that they have found nanowires & carbon nanotubes in Damascus forged swords. One Viking form, doubtless inherited from the Kelts, of folded steel uses twisted wires. I know some knife makers today using stainless cable as a starter for fine quality knives. In and out of the coals as you shape it gives stripes of high carbon steel and incredible hardness with flexibility. Japanese Samurai blades were multi part construction, using a clay mixture to differentially insulate the edge during heat treating. The line where the clay is cut away creates the Hamon line and the curve of the sword itself. A lot of art goes into the detail of the hamon line and an expert can tell the difference between makers and schools at a glance. wavy lines are common, but sometimes that fine detail can be quite intricate. The real reason for the complex construction of Japanese swords grew from the fact that local steel was mined from sand/iron deposits and the quartz had to be literally beaten out of the iron. A huge amount of labor goes into fine blade making. I have a small blade from Helle Norway made from stainless damascus and it keeps an edge very well, even cutting leather and rope.  | ||

Aesquire |

http://www.ncjsc.org/gloss_hada-1.html http://www.tameshigiri.ca/2014/05/13/evaluating-an d-appreciating-nihonto-antique-japanese-blades/ | ||

Aesquire |

http://www.tameshigiri.ca/2014/09/14/putting-the-c urve-in-a-katana-via-quenching/ | ||

Bluzm2 |

Aesquire, I spelled it wrong.. https://en.wikipedia.org/wiki/Damascening Here's the link to a blurb on the Eastwood site. http://www.eastwood.com/engine-turning-damascening -how-to-instructions-buyers-guide | ||

Aesquire |

I learned to do that with a dowel and abrasive. ( valve grind compound, for example ) ) Solid abrasive rolls just seems like cheating. I'll order a kit. |