| Author | Message | ||

Billyboy |

Changing out my muffler so I figured I'd change the oil in the primary, too. Drained the primary and went to remove the derby cover. The bolt heads were mostly stripped. Tried several sizes of torx bits, then Grabit Screw remover (which snapped). Any suggestions? Seems like there's some heavy duty loc tite on the bolts. I'm thinking about cutting a slot in the bolt head and using a large flat head screwdriver.... | ||

Jramsey |

3/16" 135 degree split point drill bit . Drill about 1/32" past the the bottom of the torx head depth. Follow with 1/4" 135 split point till the heads come off. With heads/derby cover removed use pliers or vise grips to unscrew remaining bolt then replace with button headed hex. | ||

Eboos |

I never understood why so many people had problems with the derby cover bolts. | ||

Natexlh1000 |

I had a similar problem. Turns out, when I was installing it, I had screwed in one FINGER tight but all the way in and then torqued the remaining three. What had happened was that the other three screws applied a lever-effect to the first one and made it essentially impossibly tight. I had fixated on this screw first and destroyed two tools trying to get it out. Tool number three, I tried a different bolt first, it came out easy, so did the others. THEN the final one, the one that was giving me such a hard time? Finger tight!!! Took me a good deal of head scratching to see how that happened. | ||

Aesquire |

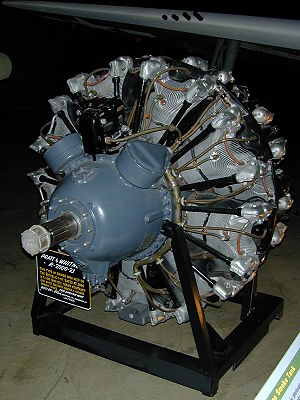

Derby bolts get exposed to extremes of heat, corrosion, salt, dirt, sand, alien waves, etc. That's a fact. My opinion is they get poorly torqued and are just a shade under engineered.... It's just a freaking cover, but to work properly it should have 2-3 times as many bolts as they actually use. Consider it WW1 tech. It needs WW2 tech. Consider the bolt sizes and spacing on this engine.  Or this American Iron  | ||

Aesquire |

The Supercharger end is even more a case of bolt fetish....  http://en.wikipedia.org/wiki/File:Packard_Merlin_V 1650_7_3.jpg That's 2 supers, one feeding the other. But check out the valve covers. Gives me tingles. | ||

Swampy |

Cork gaskets, prior to silicone they had a habit of spitting out from under just about any cover. | ||

Billyboy |

Thanks for the suggestions! | ||

Jramsey |

Eboos,you are 100 per cent correct, the quad seal/o-ring is only allowed to compress "X" amount by the case/cover design, The average non educated home wrencher ( nothing against the OP)look at it like its a flat type gasket and keep tightening the cover screws hoping to make the seepage quit when the only thing required is a new $1.80 seal. and slight finger pressure on a hex key. | ||

Sparky |

Side Story: I complained to the Service Writer (Fred) at Bartels' once for them over-torquing those (derby cover) bolts and he replied with something like, "Well, you hit them with an impact driver first, didn't you?" "Uh, no I didn't" says I sheepishly. So, from then on, I made a mental note to use that tool or at least rap them lightly with a hammer if those/any screws don't easily loosen with my grip on the handle. Impact driver has saved me from using profane language many times.  | ||

Ourdee |

I never had any problems in the days of philips heads and using impact drivers. | ||

Billyboy |

Interesting, Sparky. I started out with an impact driver, and thought that was what I did wrong! No offense taken, J. I didn't put the bolts on in the first place, the last place to service it was the dealership. I figured it was high time for me to start doing my own work. I've made some mistakes, but I've also gained a better understanding of how my bike works. Thanks again... |