| Author | Message | ||

Bluzm2 |

I just had mine apart again this weekend to replace the crank seal. I have a few pictures I will post when I get time. Pulling the tranny is VERY easy after the primary drive parts are off. I made a primary pully/clutch basket holder tool that I will post the dimensions. It's just a hunk of steel the correct length and end profile to lock the basket and pulley. Brad | ||

Bluzm2 |

Henrick, When you put in the new style crank seal, did you have any issues with the rubber on the outside of the seal wanting to peel away from the seal before it was completely seated? I buggered the first one that way, fortunately I had a second seal on hand. It would have probably been fine but I didn't want to do the job again. BTW, the insertion tool worked fantastic! I'll get it in the mail and back to you this week. Thanks TONS!!!! Brad | ||

S3thunder |

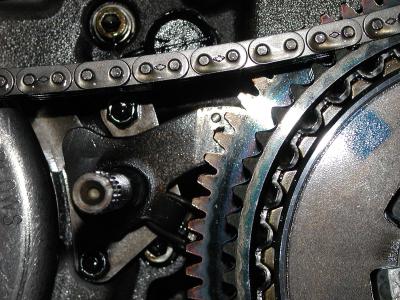

Reepicheep et al, I am doing as suggested but I need some help. I want to know how loose is too loose on the primary chain with the cover off??? Also please look at the pics and know that what Reepicheep said is so true. I think I may have more troubles too as the shifter shaft assembly arm that goes behind the ring gear shows definite marks of rubbing the gear. Do I have to put the cover back on and adjust tension to know if the chain is too worn ?? Thanks     (Message edited by S3Thunder on November 03, 2004) | ||

Captainkirk |

S3, Relax. The chain will be loose as a goose without the tensioner installed. The wear marks in the primary cover are also pretty *normal* for this situation, and unless they've worn through are no problem. Definitely install the new-style tensioner. Where you need to go next is to lock the primary sprocket and clutch basket, remove both nuts,(careful, clutch nut is LEFT HAND THREAD) and pull both sprockets and chain as an assembly. This will allow you access to the Whatchamacallit Bumpy Disc (detent plate) and e-clip that holds it on (little ba$tard that it is)...if it's not already cracked or broken. Carefully inspect the Bumpy Thing for wear on all the ramp surfaces. Better yet, just replace it. It's cheap and the new design is much better- shifts are much more precise and neutral seems easier to find than with the old-style. It also appears to be steel instead of aluminum. Next, $hitcan the e-clip. Do not use it over regardless of condition. I seriously doubt you have too much wear on your primary chain. Check the teeth on your sprockets for cupping and uneven wear. If these are OK your chain is probably OK too. You can remove the shift pawl and inspect the damage. If it's just wear marks, blend them out with a file and sandpaper. Mine weren't bad at all. Check the pins in the end of the shift drum to see if any appear to be backing out-use a straight edge if you need to. This is impossible to check without pulling all that other crap out of the way. Let me know what you find, and if you need any of the upgrade part #s. | ||

Reepicheep |

Nothing alarming looking at all there, you are good. I agree with Kirk. The only thing I would add is once you get that clip off the *detente plate*  you are REALLY REALLY close to being able to pull the tranny and give it a good inspection. Like 4 bolts and an additional 15 minutes. If it were me, and a high milage bike, I would pull it and inspect it and the 5th gear drive assembly (in situ). Look for raised lips on the slots the shift forks slide on, and file them back flush if they are raised. you are REALLY REALLY close to being able to pull the tranny and give it a good inspection. Like 4 bolts and an additional 15 minutes. If it were me, and a high milage bike, I would pull it and inspect it and the 5th gear drive assembly (in situ). Look for raised lips on the slots the shift forks slide on, and file them back flush if they are raised. | ||

Bluzm2 |

S3, Go back in and edit your post. Hit enter after each photo to place them vertically instead of horizontally. Make everything easier to read! I too agree with Capt and Bill, your chain looks fine. The grooves in your primary cover are nothing, you ought to see mine! AS long as they don't go through to the screw passage, your fine. | ||

Captainkirk |

Thanks, Reep, for adding that bit about the tranny! I forget to mention, I inspected mine with a mirror and flashlight, and it looked fine, otherwise that was the next step. S3 how many miles? | ||

S3thunder |

Thanks for all the help I am currently @53,500 miles I will probably pull the trans as I have a problem with it jumping in and out of 1st gear. It will go in and out several times in a row taking off from a stop on occasion. I have another tranny that is new and has some kind of coating on it. Don't know it's year or use (as in Buell or Sportster). I don't know if cleaning it with a solvent is good or not. Bluzm2 if you can tell me how to edit a post I will be glad to do it. Thanks very much.  | ||

S3thunder |

Bluzm2, I found the little icons on the far right and hope this repost helps. I like it better too. | ||

Reepicheep |

Definitely pull the tranny then. If for no other reason, just because you can, and just to say you did. And at 53k, I would be looking hard at the 5th gear drive assembly (remains in the case) once the tranny was out. And I agree with Blue, those primary cover grooves tain't nothin. Just replace the bolts when they are cut more then half way through  And be careful with the diagnosis. I had the "hop" the first time, and it was worn dogs on second gear. Never more then one hop. It then came back, felt identical, but would sometimes hop more then once. I was about ready to tear into the tranny again, and on a hunch waited until I first replaced the rear tire (from a Dunlop D220). Imagine my delight, when the problem was instantly fixed. The wheel hop was *amazingly* violent. | ||

Henrik |

Brad; AFAIR I didn't have any issues with rubber peeling off the seal when inserting?? Glad it worked out for you. Henrik | ||

Kahuna |

good day everyone, while we're on the topic, i'd really appreciate your help. i replaced my chain tensioner to the new style, and ever since, finding neutral from first is almost impossible. i have no issues getting neutral from second, but first seems to be a no go. any ideas? could it be that my chain is too tight? many thanks for your help. | ||

Bomber |

Kahuna -- my experience says that you primary chain is likely too tight, although I've heard tell of too loose causing the same symptom -- adjust it carefully by the book, and the problem should disappear luckily, the adjustment is easily done -- just make sure you are adjusting with the chain at it's tightest point | ||

Reepicheep |

Adjust the clutch mechanisism by the book while you are at it. Fluid levels can make it fussy as well. | ||

Benm2 |

Well, I pulled the tranny, as had been suggested. Interesting things I found: 1. The engine sprocket nut was loose. Set myself up with the breakerbar & such, and threw a chunk of wood between the sprockets (the HD primary drive locking link), and prepared to heave-ho. After all, its tightened to 180 ft-lb or so. Came off with NO appreciable resistance. Couldn't tell if it had walked off or not, but I'm currently suspicious of it.

Reep, experience is a bi**h of a teacher, no? I'm hoping that was the cause of my mystery noise, as its easy to fix. 2. The bumpy thingy looked fine, mine's a 2000 so it should be the new one. It's steel, and some of the edges were sharp where it had been ground. They've been honed off. The e-clip shattered upon removal. 3. The transmission looked absolutely fine. I pulled it & visually inspected it. The fifth gear drive assembly looked fine also, all the needles were still contained. I didn't pull apart the shift drum, right now the tranny's been put back in & torqued. 4. The primary cover had some wear marks from the chain in it up top. Not too deep, but they're there. 'Splains some of the shavings at least. I'm hanging my hat right now on the loose stator & loose primary chain. The bummer of this situation is IF they WERE the cause, I could have had them corrected at the track by retorquing the nut & adjusting the slack (before I broke the shoe, anyway). Live & learn, I guess. | ||

Reepicheep |

Great news Ben! When mine was loose, it came off just like you describe. On my bike, it sounded like a crank bearing failure, which made for a really bad ride home. Sounded worst at idle / in neutral, if the engine was loaded it sounded fine. My stator died shortly thereafter, not sure if that was related or not. Sounds like you are in good shape. Let us know how it sounds when you spin it back up... | ||

Bikecraz |

Having trouble adjusting the primary chain on a 2000 S3T after updating to the improved tensioner. After adjusting the clutch per the manual,I moved on to adjusting the primary chain. With the engine off I tried placing the transmission in 5th gear to rotate the rear tire to find the chain's tights point. However I cannot shift the transmission pass 2nd gear. Did I miss something? I assume that I would be able to shift through the gears with the engine off. Thanks | ||

Road_thing  |

Craz: If you can spin the wheel, it shouldn't matter what gear you're in, the object of the drill is to find any tight spots in the primary chain and make your adjustment at the tightest spot. You might have to rotate the wheel after each shift to get it to go up to the next gear. I assume you have the back wheel off the ground (and that you're not trying to spin the engine with the spark plugs in place!) rt | ||

Captainkirk  |

Ditto. What I did was a)with the rear bodywork off, attach a ratchet strap to the rear frame: tie this up to one of your garage joists, and as I tightened the strap b)tapped a piece of 2x4 under the swing arm, then repeat until the tire is no longer touching (this, assuming you don't have a swingarm stand) As Road Thing said, it really doesn't matter what gear it's in. (Do remember to remove the plugs, tho!) | ||

Reepicheep  |

Does the S3 have the same hollow rear axle the Cyclone has? Get two cheap jackstands, and a 3 ft piece of rebar. Put the rebar through the back axle. You can lean the bike over onto the first jackstand, and ratchet up the second, then vice versa. Very easy and safe, takes me 2 minutes to have the back wheel off the ground. | ||

Al_lighton  |

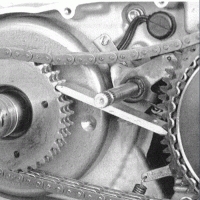

My Stator died recently on my S3, had to replace it. I've been into my Primary and transmission on my S1W a few times, every time I took off the clutch basket/rotor I farkled around with rags and blocks in the primary chain to lock things up to get the nuts tight. An electric torque wrench works great for getting the nuts off with minimal fuss, but getting torque on the big nuts for both the flywheel output shaft and the left hand thread on the tranny mainshaft has always been a bit of a bear. And the output shaft nut is not to be trifled with, more than one Bueller has lost torque on that nut, and it's bad tiki when it happens. The manual says to use this locking bar:  It made the job so darn easy, I decided to add it to the store. At a mere $18.95, it's one of those tools that any home mechanic that is opening their primary should have. See here Al | ||

Ezblast  |

Can a fairly new primary gasket be reused or should I just use a new one - the used one has about 800 miles on it. GT - JBOTDS! EZ  | ||

Chris_mackay  |

You can reuse it but answer 2 questions. How difficult was it for you to take the primary off? Would it be worth it to have to do it again if the old gasket leaks? | ||

Ezblast  |

It was nothing hard to do but it was time consuming, I just want to know if the gasket is reliable for reusage , but I do have another hanging around ready to use. Figure the primary tensioner is due soon to be swapped out for a new shoe - GT - JBOTDS! EZ  | ||

Reepicheep  |

The metal ones reuse pretty well a couple times. The paper ones, even when looking perfect, always leaked on me when I reused them. (note these are tube frame datapoints, might work better on the blast). | ||

Ezblast  |

Yeah - its a metal one - I put it on myself - thanks Reep - thats what I wanted to know - I just want to do a quick - lol - in and out to switch out shoes. GT - JBOTDS! EZ  | ||

99x1  |

Opened up the primary today - chain adjuster is actually broken, but the crack pushed up and sort of welded itself back together on the outside edges. After removing the center bolt, one tap with a hammer separated the pieces. Actually had no indication anything was wrong - but I'm glad I checked!   | ||

Captainkirk  |

Looks all too familiar...  | ||

Djkaplan  |

I hate to bring this up again, but what is the PN for the good shoe assembly. I ordered one from the Harley dealer and the order slip had PN#39922-00Y on it. Is this even remotely close? I have a bad feeling because the guy at the parts counter was a complete dolt. He explained to me that the Buell and Harley Sportster shoe assemblies were not interchangeable. That's news to me. | ||

Reepicheep  |

From the top of this page:

I think the 00Y indicates that you have an even newer part number then that, so you are probably fine. The difference is obvious when you see them side by side. If somebody chimes in with an authoritive answer, I will update the info at the top of the page. |

Learn this... Don't even think about overtightening your chain. Be sure to set its slack within the specified range when the chain is in its most taught orientation. The Hayden M6 tensioner is not a reliable device in a Buell primary. Stay away from it.

Learn this... Don't even think about overtightening your chain. Be sure to set its slack within the specified range when the chain is in its most taught orientation. The Hayden M6 tensioner is not a reliable device in a Buell primary. Stay away from it.