| Author | Message | ||

Grndskpr  |

Well i decided to dive in and give myself a winter project, the Buell needed to be rebuilt, and now i am in that very process and i have a few questions, first let me preface this by saying there are many outstanding builders out there and all are far and above me in all things Buell, however i would like to try and do it myself more for fun thank anything, plus i feel it will be a learning process so here goes What should i do about the crank, its a 98 1200 XL, and i have been told that with its miles i am best replacing or rebuilding it, with that in mind should i upgrade the rods while i am in there or should i just go buy a new set from Buell(the 2000 and up ones) and have my case machined for them???? please expalin either way, plus can I rebuild the crank or is it best left to the experts?????The manual makes it seem easy enuff, but i have taken a good look at it and it may be one of those deceptive type of deals, also while its apart what bearing should i replace in the case, or should i just replace them all and make it simple, i think i will start there and ask as i go along on this little project thanks in advance R | ||

Mikej  |

Carillo rods, machine and balance and match the crank and pistons to match. Send out the machining and balancing to a competant shop, do the assembly at home. If 95% of your engine hours will be below 5,000rpm you can probably stay with stock stuff. Just an opinion. | ||

Firemanjim  |

Seeing as how the crank needs to be assembled in a jig and flywheels properly aligned,and the nuts torqued to Magilla Gorilla specs,I would have it done.And Carillo rods are exorbitant.The stockers are good for a bunch of power,and if you don't like them get some S&S ones.They have a couple of different grades.Have to whole thing balanced and you will be good to go.There is a bunch of measuring and fitting on putting new bearings in crankcase so it may be easier to have crank assembled and fit into the case half as it needs to be pressed --in and watch the seal install,also.Bearings are available at any bearing supply house for cheap.Once the crankset is in the case half its an easy assembly job from there. | ||

Hoser  |

Roger: What Jim said ........... Rod fitting is a specialized job , quite often a used set of rods will be out of round and barrel shaped when measured , using precision bore guages. Specs call for rod big ends to be round and straight to less then .0002" , it's not unusual to see an investment of several thousand dollars in precision measuring tools , let alone the cost of a Sunnen hone or the necessary mandrels to fit bearing races , bushings and such. On the plus side , a set of "seasoned" rods tend to hold thier shape better than new rods when they are properly sized to a new set of bearings. Crank pins are available in oversize to enable custom fitment when rods must be honed a half a thou or so to true them up to being round again. Stock HD rods are sufficient for every day use , up to and including a mild competition build , so a Carrilo rod set would be a little extravagent for a standard rebuild , S&S rods are availble in replacement and heavy duty versions so if rod replacement was necessary there certainly are options to consider. There are alternatives when chosing a crank pin too , many of them being superior to genuine parts. Assembly / truing of flywheels is done in a truing stand or between centers , involving more specialty equipment. What all this means (coming from a guy who does this for a living )is , this is not a job for the "do it yourself" type due to the equipment required . I'm fortunate to be equipped with the tools to remove , dissassemble , rebuild and true crankshafts at home , the honing / sizing of bearing races is done at work where I have access to that type of equipment. It's pretty rare to find a home shop equipped to do any lower end overhaul work at all , based on the investment in tooling required. I would advise you to consider having your crank / rods rebuilt , using quality parts ,this is an opportunity to have the assembly balanced , if heavier or lighter parts are substituted during the rebuild , count on spending a little more to have the flywheels balanced. I did the bottom end on my S2 earlier this year , balanced the wheels while it was apart and found it to be time well spent. | ||

Grndskpr  |

Thanks guys that was the direction was was thinking, and since i am kinda doing this for fun and to freshen up the bike no sece in making it lick work, plus i had a long talk with the dealer, i am lucky to have one of the premier dealers in the US, so i think i will have them do the lower end, makes sence all the way around, plus there ties to Revo and some other racers makes them the best in the area for my needs, guess now i have to figure out what size i want to go, or just freshen her up to stock specs, going to be a long winter thanks again R | ||

Hoser  |

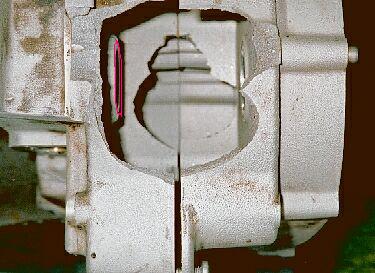

Roger : If you happen to come across a later crank ( a throw away when service is needed ) , it can be fitted to earlier crankcases by having .085" machined from the area shown in red below........  Upside of doing so , lighter rotating weight = quicker reving . Downside - some time in 2003 the rods were changed to a lighter duty part , they look kinda wimpy . Machining required as already shown , but not a big deal , I've done it here at home. If the crank you intend to rebuild is the heavier XL version , consider the Lighter Buell crank as used on 96 to 99 , it's not as light as the later crank but can be disassembled and rebuilt when needed and no case mods are needed. I have seen them on ebay , and reasonbly priced too , price of new units has gone high due to production being shifted to current parts. I believe the SI crank is 3.5 lbs lighter than XL cranks , the 2000 & up cranks are another 3 lbs lighter than the S1 cranks , heres a pic of a 96 S1 crank , parked next to a 2001 crank.  | ||

Hoser  |

This machine , without tooling is 20k , the mandrels and related stones and acessories , another 20k + , sadly many dealerships do not have one , choosing to job out that type of work , losing control of quality in the process. Basically what is happening is we have turned into a throw away society , it's shocking how many young "tradesmen" have never even ground a valve before , ....sad , it's rare to see auto shop classes offered in High schools anymore .  | ||

Sportyeric  |

The Sporty's getting a new bottom end this year,in about a month. I imagine such work is best done locally due to shipping costs, even for a stripped case-and-crank combo, yes? | ||

Jmartz  |

Hoser: Is the diameter of the 2001 larger or is it an optical illusion? The cranks are resting on a rather shiny surface that distorts the view. | ||

Hoser  |

JM : The diameter is the same , I should have repositioned the parts so they wern't at an angle to the camera lens. Eric : Shipping ?? have it done there in Hongcouver | ||

Jmartz  |

Hoser: Could the '96-'00 be milled down? | ||

Hoser  |

JM : Yes and no , it depends on the location of the holes that the factory drilled in the existing pair of flywheels when the balancing took place . If the holes are not drilled to a depth that would present the risk of breaking through when the wheels were turned on a lathe , then yes , you could lighten them , an inspection of said holes is necessary before begining such work. The holes are very close to the rim of the flywheels , this would not allow the flywheels to be turned to a profile known as "knife edge" . Sportster flywheels could be turned to lessen the mass , as they are much thicker in cross section than S1 wheels , they could be knife edged as well if the location and depth of the balancing holes would permit such machining to take place. In any case the decision to machine any flywheel would be based on good judgment and experience of the person performing the mods. It would make more sense to consider the use of late model "low inertia" crank shaft when planning an engine build that calls for less rotating mass. | ||

Hoser  |

I should also mention , S&S flywheels can be special ordered and configured as desired , knife edged , lightened etc. , this also makes it possible to use the earlier pinion shaft that is splined , a much stronger design than the "T" key used to hold the pinion gear and oil pump gear on the OEM pinion shaft. The OEM wheels use integral wheels / shafts , meaning the pinion and sprocket shafts are forged as one piece with the wheel when manufactured , S&S are bolt together like pre Evolution wheels were , shafts can be changed , like if you had to buy a crankcase with an offset timing chest to allow for 4" bores , a longer pinion shaft must be used . S&S has a long list of options to mull over if you were to build a custom engine. | ||

Reepicheep  |

Sorry to take a tangent here Hoser, but would there ever be a case where the T key for the pinion gear would *not* be strong enough, but the spline *would* be? I am having a hard time imagining a failure mode for a positive displacement oil pump that would destroy one but not the other, seems like things will go "really badly" regardless. Pump or Die!  | ||

Aaron |

The woodruff key is directly under the oil pump drive gear and only a little bit of it protrudes out and keeps the pinion gear in alignment. With heavy valve springs, it's not uncommon to shear off that little bit of the woodruff key, allowing the pinion gear to slip and pistons to go slamming into valves. Some people have been known to overtorque the pinion nut to keep this from happening  ... but the best solution is as Hoser points out, to use a splined pinion shaft as used in 86-87 Evo Sportsters, which can be done when you buy S&S wheels. ... but the best solution is as Hoser points out, to use a splined pinion shaft as used in 86-87 Evo Sportsters, which can be done when you buy S&S wheels. | ||

Reepicheep  |

Gotcha! That makes sense. The oil pump pinion gear is not the problem, its the other gear, the one that makes the valves miss the pistons  I was looking at the oil pump drive gear on my desk (the same one in my profile pic) and thinking there is *no* way that thing is going to strip that woodruff key on a running engine without breaking... well... everything. | ||

Sportyeric  |

While we're in there, do I recall that there is a doohickey to spray (cooling) oil on the bottom of the rear piston that is, maybe, in the XB and that could be easily installed on ours? | ||

Jmartz  |

Seeking quicker acceleration while retaining the stock cases would be possible by reducing the weight of the crank assembly. I am a little reluctant to use the pressed pin design as it involves other mods to the old case. I would love to build and S$S 4 x 3.5 but for a log time they told me that it could not be done because the nuts holding the shafts would hit the rods. Turn out this is only a problem with the 1.5" dia. crankpin. Other issues still persist. S$S parts are generally intended fro drag racing and are heavier than stock. Their rods are so that weight must be added to flywheels in order too achieve balance. Also the cases are thicker everywhere for strength when you launch. Somebody once told me this is a torque motor not a HP motor. |