| Author | Message | ||

Lars |

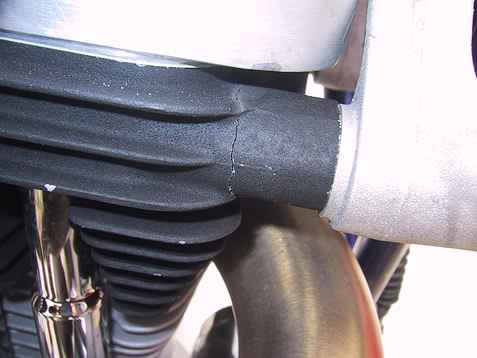

What is the deal? I don't do wheelies or stoppies and it still broke after only around 16K miles. Any one else have experience with this? What is the least painful way to get the old one out? Does the front end need to be pulled to gain access? Should/would the company cover this? Any mechanical wizards with ANY information or insight would be appreciated. Specifically it the was left side. I think both should be replaced once into the job. | ||

Ralph |

Lars, I would pull the head. In the long run it'll be the easiest. You will not need to pull the front end. Plenty of room. It is possible the company will cover this but you'll need to shout loud and not touch anything. Definatly replace the unbroken bolt as well. Why? Could be incorrectly installed bolt, there are about twenty different ways to torque them down now. bighairyralph no wheelies? maybe that's the problem!! | ||

Court |

Wheelies are unrelated. Do NOT remove the bolt. Call your Buell dealer. They will (SHOULD)be able to take care of this. Court | ||

Lars |

Thanks Court and BigHairy. I really appreciate your assistance. I showed the bolt to an MIT grad and he felt it was a stress fracture. I'll call Manchester and or 'sconsin on Monday. I'll have to live vicariously through all of your adventures this weekend. Lars | ||

Ralph |

Um, Lars, I didn't graduate from MIT and I could have told you it was a stress fracture  bighairyralph | ||

S2no1 |

Ralph, The difference is that you would have said: "It's a stress fracture" The MIT Graduate would say: "Based on my visual observation of the zone and and geometry of the fracture, I would anticpate that this premature failure is the result of stress. However, a detailed micrograph analysis of the shear plane should be performed to verify this conclusion." Lars, Happened, I believe to Mark-in-Ireland. It should be in the archive somewhere. Please don't take the comment above personal. It was a joke. Arvel | ||

Lars |

Hey Arvel you are right on. That is almost exactly what Chas (pronounced Chaz) said in so many words. I took no offense and caught it immediately, as I was sipping a grande' decaf latte' with skim milk with one half ounce of hazelnut three sprinkles of cinnamon and three stirring straws. I was QUITE amused by the entire enchange I dare say. ;-) Lars | ||

Court |

Lars: I have the diagrams, from 1996, that describe the condition you have experienced. Regardless of what your M.I.T. grad says the "DO NOT REMOVE" bracket situation can best be visualized by thinking of how a steering wheel puller works. Envision that "DO NOT REMOVE" bolt being 1/64" long or inserted 1/64" too far. Very fixable. Court | ||

S2no1 |

Lars, I like two stirring straws myself. Arvel | ||

Mark_In_Ireland |

Lars, The lug on the cylinder head where the bolt goes into fractured. Nobody knows the reason why, but in my investigations talking to dealers and tuners I found out that it wasn't a one off case. Buell, UK say mines the first....so read into that what you will. I hope your dealer is faster at repair work than the only authorised dealer in Ireland....  | ||

Hein |

Hmmmm, this really puzzles me. My mounting stud on the right hand side of the front cylinder broke after appr. 2000 kms. I was sooo happy with my baby after all the trouble I've been through, but at this point I'm not so sure anymore if I want to go on. This is the more or less complete story, I would appreciate input from the guys who should know... you know who I mean.. I ran the bike into the side of a car past January. Front wheel slighlty damaged, front disk badly damaged, front axle bent like a banana, forks straight (according to the dealer, I can't see any damage or imperfection). Front engine mount, or isolator, apparently touched the frame triangle, but only slight paint damage on the frame was visible. The oilfilter was ripped open by the locknut of the front tiebar. There was no visible damage of the frame or the engine. I had my doubts about the frame, was it still straight, wouldn't I need a new frame, but the dealer checked it thoroughly and assured and reassured me again that there was absolutley nothing wrong with the frame. According to them it was normal for the engine to move forward in its rubber mountings that far on a sudden impact like I experienced. Tie bar, isolator, engine mount and steering head bearings are all replaced, as well as rear isolators. After this crash a RAM single sided swingarm was installed, a braking front wheel with dual rim brakes and a Technoflex rear shock link system, together with Technoflex front springs. The cylinder heads have been ported and flowed (is this the correct expression?), crankshaft has been dynamically balanced. After the first testride after rebuild I noticed a dent in the oilfilter where it had been knocking into the tiebar locknut. I commented about this, "happens a lot, no problem" I was told. The engine runs like a dream, really smooth, but very powerful. Bike handles better than any Buell I've been on. Very stable, even in those high speed "oh shit, shit, I am not gonna make this" turns. No wobbles, a real shock, etc etc. Front brakes are great. I really thought that I was finally there. It lasted two weeks. After only 2000 kms the right stud on the front cylinder broke. Furthermore I can see extensive paint damage on the inside of the right hand of the frame triangle where the engine mount has been touching the frame. The left hand side of the isolator is really close to the upper rocker cover (my thumbnail won't fit between). And it looks like the tiebar locknut has been touching the oil filter some more times.  the broken stud  the damage on the frame (hard to see, but the paint is scratched off to the bare metal, rubbing marks are also visible on the engine mount) The bike is going to be trucked to the dealer Tuesday morning and I would appreciate your thoughts on this before I see them. My theory is that the front section of the frame is not in line, which caused the islotar mount to touch the frame, which caused the mounting stud to break. Is this making any sense? Or is it possible that the dealer did not follow the correct mounting procedure causing stress? But why is the isolator touching the frame then? Are there different types of isolators and could they have mounted the wrong type? Cylinder heads have been on and off the engine some times, is there any special procedure which could have been neglected? Or should I stop riding the bike like the law is chasing me? (Which would mean that this is the end of a promising love story...) 3 last pictures before I resume mourning. Summer has finally begun and I'm bike-less, shite!  RAM sssarm  technoflex shock  Braking front wheel, what's in a name? S1WL Hein feeling like shite in hot Am*dam | ||

Mikej |

Hein, I'm no metalurgist, but I wouldn't me surprised if that stud had been stressed or cracked during the crash incident. I think the only way to have found it would have been via x-ray or magnaflux or some other non-destructive testing of the stress-point engine components like the mounting stud casting. When I hear of situations like your's, or when I see bikes like Bubba's that was seen on e-bay recently, I always remember the rule that if the crash was bad enough to bend a rim or fork leg, then you should check more than just measurements when inspecting for damage. In your bike's case, it could have started with an internal crack that has migrated/expanded to the surface. I'll let the degreed engineers take it from here, I just pay attention and learn what I can. Hope your situation is resolved quickly. | ||

Aaron |

That mount should NOT be banging on the frame. Without any actual data to back it up, it sure seems to me like it could cause that fracture. There is a very specific procedure for bolting that mount to the head, too ... I'll send it to you if I can find it. AW | ||

S2no1 |

Hein, That is one tricked out Buell. I hope your dealer can get you fixed up. Aaron, Did you mean "should" or did you mean "should not" Arvel | ||

Aaron |

I sure did. Fixed, thank you sir! |