| Author | Message | |||

Kenbull |

5 weeks ago the dealer replaced the drive belt and rear isolators on my 97 S3T with >75,000 miles on it. At 3200 RPM there is an unusual vibration felt through the foot pegs, a little above or below it goes away. The vibration wasn't there before the work, not right after. Any ideas? | |||

Bluelightning |

Have you checked the front mount? Mine was torn just slightly and I would get a vibration in the pegs around that RPM that seemed to go away when I went faster. Just a thought | |||

Davefl |

I second the front mount. Also check the front muffler mount. I get about the same vibration from either. | |||

Lake_bueller |

Sounds too simple but CAREFULLY inspect the front tire. Very, very possible it's cupped. | |||

Ocbueller |

Check that belt tension! SteveH | |||

Kenbull |

I've experience the vibration with the torn front rubber. This vibration is felt distinctly in the foot pegs at 3200 RPM. The dealer installed the belt tighter than I would have, but I don't think its too tight. The front tire is OK. Would the transmission sprocket cause it? | |||

Henrik |

If you think the belt is tighter than you'd have installed it, go loosen it right now. Tight belts lead to very bad things happening with your tranny bearings. Not to be taken lightly. Henrik | |||

Softailbuell |

1. Motor mounts (front and or rear), either too loose or torn rubber. 2. Too much belt tension 3. rear axle alignment in relation to the frame. Those are what I would check. | |||

Kenbull |

Thanks, Iíll be riding to work this weekend, that is until Hurricane Frances comes. It be the next week before I can report back to you with the changes. | |||

Jammer |

Kenbull, I ride a 97 S3 and have had the same problem. It was the front muffler mount bushing that was bad. Just another thing to check if you haven't solved the problem yet. Jeff- | |||

Kenbull |

Discovered the problem with the vibration @ 3200 RPM. Itís the front link, the cap screw has lost its torque. The female threads would no longer hold the screw, in fact I could remove the cap screw without turning it. I believe the Banke Brace is the root cause of this failure. Too much stress at this point. The fix is in progress by filling the hole with Titanium Putty and tapping it out with 3/8-16. So far this fix has failed. Canít get any torque on the cap screw, or not enough. Iíll try again this week. Is there a better fix? | |||

Blake |

What do you mean by "front link"? | |||

Kenbull |

The tie bar at the front. Keeps the engine in line with the frame. | |||

Bomber |

the link that runs from the frame to what would seem to be the generator housing? in the engine cases? the hole in the cases stripped? the Banke should nothave casued that -- later tubers had a piece welded in the frame to replicate the function of the banke piece, and I don't recall hearing of that hole stripping . . . . not saying you're wrong -- I'm far from an engineering type (havn't even stayed at a holiday inn express lately) -- seems a strange failure mode right as rain, Blake, thanks for catching my braino (as opposed to a typo) (Message edited by bomber on September 07, 2004) | |||

Blake |

John, You mean "the Banke should not have caused that", right? | |||

Kenbull |

The Banke Brace has been removed. The repair is complete with the cap screw snug tight. I believe if this model had a top Tie Bar, this wouldnít happen. Is there a way to add a top Tie Bar? | |||

Bluelightning |

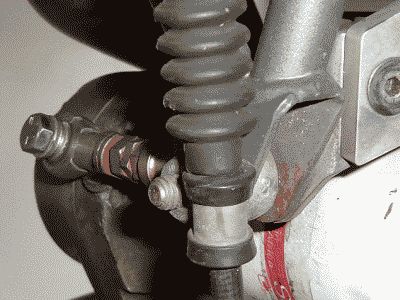

Ken, Just out of curiosity, can you take a pic of your repair, so that we can se what part you are talking about. There seems to be some confusing thoughts as to which bolt got stripped out. There is a lower link that goes from the frame to the front of the oil filter mount and there is the upper link that crosses in front of the front engine mount (which also mounts to the head at 2 places). The front engine mount has been known to strip bolts and even break them, which is a major reason for the development of the frame brace and on the later bikes, the welded in brace. Thanks | |||

Davefl |

I do not see the need to remove the Banke frame brace. A friend of mine has had one on his bike for well over 50,000 miles with no failure and the '99 up bikes had a brace welded into the frame. I know you had a failure but I don't think the brace caused it. I would bet that bolt has been over tightened sometime in its life. | |||

Lake_bueller |

Ken...if you're looking to dump the Banke brace, ping me at awinefan@hotmail.com | |||

Kenbull |

Bluelightning, Iíve tried to upload pictures of the lower link, but the file is too large. The lowest size that I can achieved with the Adobe Photo is 140K. Iíll keep trying. Iíve experienced many problems with the front isolator mount. The first year the 7/16 cap screw broke, in fact the mount broke. The dealer took care of that time. Two years later the bike was at the dealer for other service when the mechanic was checking torque and rung off the same fastener. A socket screw was installed in 1998 that was too short! The mechanic that install the screw developed a memory lost. That was the first time I drilled out the broken screw. Since 2000 the same cap screw has broken 3 times. The Banke Brace was installed in 2001, so the brace has made no difference with the reliability of the fastener. Now, I change the 7/16 cap screws every 5K to 10K miles. If this model had a upper tie bar, I believe these failures wouldnít occurred. The brace is on the shelf for now. | |||

Kenbull |

|