| Author | Message | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Marksm |

This company has cartridges in many sizes. It's European though. http://www.coolride.de/en/Shop/ | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Reepicheep |

Cool! Never heard of CoolRide. Looks like this unit (http://www.coolride.de/en/Shop/Automatic-Power-Con trol-Unit-GHZ-D.html) is similar to my "rev 1" version of this device. The one I ditched, to come up with this much better version.  Blake, the overshoot is inevitable. The lag from when you start pumping heat into the system to when it "makes it out the bars" is on the order of a minute. There is too much thermal inertia. If I knew you were going to stop at the next light, I could back off the power 60 seconds before you get there to keep it from over shooting... but that would require predicting the future (or maybe snooping your GPS  ). ). Instead, I just automatically compensate for the overshoot with the controller. So while it still overshoots, it has started correcting before you even know you had a problem. Like you observe, without a big and complicated peltier cooling system, I can't drive the system cool, I can only drive it hot. If I could drive it both directions, or if it didn't have such absurdly high latency, I could control it really tightly. With my controller managing it, the overshoot isn't bad though. It has started adjusting for the problem within fractions of a second from when it started. It's when you are trying to do it on your own with a switch while riding that you end up oscillating between "frozen" and "blistered". You are right about tweaking the loop. I thought it would be easy, and it turned out to be really hard. And it required a normal but pretty sophisticated solution to be combined with two other simple but really non obvious solutions in order for it to work. Will somebody "steal" this design? If it gets successful, then yes, somebody probably will. Will somebody license it? I made a couple light runs at it, and there was some interest, but at the end of the day this is a niche corner of a nice market. Tooling and packaging and manufacturing are going to be big $$ costs. It's interesting, but not a compelling case. So my best bet at this point is to open up the design of the hardware. That's a no brainer, you cant copyright or license a circuit. The harder question is if I release all the software. That's where the real "secret sauce" is. The normal solution here is to release the software under a "free for non commercial use" license. So we can play, and if somebody wants to sell anything, they have to license my code. The problem here is that once I open up the code, it's only 10 pages or so of C source. And of that, only 50 lines or so is really the secret / clever stuff. So you could have any decent programmer read it, understand it, shred it, and go write the same thing from scratch in a few days. And that assumes they are ethical.. they would probably just write the new code with a print out of the old code on the desk at their elbow... maybe 4 hours work to get it running. The typical defense there is to try and get patent protections, but that is high up front costs ($200 for a one year provisional patent, $1000 to $10000 for a proper patent). And remember this is a "niche in a niche" solution. And a patent is often just the setup for later litigation, especially when you have built what is to some degree just a thermostat. So why ruin a perfectly good hobby trying to turn it into a business based on an iffy bet. Especially if I already have a great "day job" (which I do... its pretty amazing some days). And on top of all that... (and sorry for going here for people that don't want religious threads), at my root, I'm a believer in unconditional love and unconditional blessing of the people around me. I get off on using the gifts and blessings God gave me to recklessly bless the people around me. So what the hell, why not just give it away?  And as hobbies go, sitting down at the kitchen table next to the family (who I like) while they watch Survivor (which I find tedious) and soldering up a few controllers makes me really happy. Charge enough per unit to break even on parts and materials, so the hobby breaks even. I then have free happiness... everyone should be so lucky! (Message edited by reepicheep on October 28, 2011) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Blake |

I'm still not clear on exactly what the controller includes. You mention inside the handlebar heating. Is that the only solution? Why not hand grip heaters? I'm still confused about what exactly the product is and what exactly it is supposed to do for someone who makes or buys one. I think you are so close to it you're having a tough time seeing it from an ignorant person's (my) point of view. Can you put into words what the advertisement on American Sport Bike would say if they were selling what you have designed and programmed? Would it be something like... "Provides precise selectable thermostatic control for any handlebar grip heater?" What temperature settings does it offer? Pleas help me understand; I'm ignorant.  | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Schwara |

100% agree on the last few comments about both blessings and hobbies. Now I just have to convince my wife that having the Uly in the living room over the winter will allow me more time with the family while spending time on the bike ... sadly, I don't that will happen. Oh well | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Reepicheep |

Marketing Brochure: Smart Heater Controller Ideal for Motorcycle applications such as cartridge grip heaters On a 40 degree day, you as a motorcycle rider experience a temperature swing of 25 degrees simply by coming to a stop. Meanwhile, changing the setting on your heated gear (such as a cartridge grip heater) requires over a minute before you can start feeling the resulting change. And by the time you switch it higher (because it is too cool) or lower (because it is too hot), it will continue to "go wrong" for a minute or more before you can feel your new change. Which is probably wrong too. At best this means a distraction while riding. More typically, it results in a long and frustrating search for "the new right temperature" any time you slow down or speed up. This controller is the solution to that problem. It constantly and automatically monitors the temperature of the grips, and constantly adjusts the power, in order to keep the temperature from over or undershooting. Just start the bike and ride, and the controller manages the heat, readjusting as necessary every few seconds. Being fully automatic, this controller also completely eliminates the need to mount any kind of switch or knob. Stop drilling more holes in an otherwise perfectly good motorcycle. You simply hook the controller up to a fused accessory line, mount it next to the heat source (it is sized to fit inside your bars). From then on, the controller delivers heat when it is cold, and keeps the heat off when it is warm. No switches, no knobs, just heat when you need it. Because the controller is "smart", it can include another critical feature. Motorcycle charging systems don't have much margin. They have small batteries that are already being sucked dry by a headlight when the bike is not running. How long can your battery afford to sit there on a cold day, running heaters and headlights in the drive way, when you have switched on the ignition but not started the motor? Long enough to get on your gloves and helmet? Long enough to discuss last minute route plans with your group? Will it start when it's kickstands up? And what if your stator fails? Where will you be, and how far will you need to get if you want to avoid being stuck? How much further could you have gotten without 30 to 50 watts of heat being pulled from the battery just to keep your fingers warm? And what about low RPM and heavily loaded charging systems? Many motorcycles still use permanent magnet charging systems... so the power available is directly proportional to RPM. If you are stuck crawling along a muddy road or traffic jam, and forget to turn off some accessories, are you doomed to be soon pushing? So the controller looks at more than temperature in controlling the heaters. It also constantly monitors the voltage your stator is producing. So long as the voltage is high enough that your battery is successfully charging, the heat will stay on. As soon as your bike drops below this minimum charging voltage, the controller stops turning on the heat. Better cold and moving, then warm and pushing. This is also all automatic, and happens many times a second. This allows you to "overload" your charging system. At low RPM's the least important load (for example your heated grips) will automatically turn off. As soon as your RPM comes back up and more power is available (even for a fraction of a second), the controller will start harvesting whatever surplus is available to try and bring back the appropriate heat. Mounting is simple. For cartridge heaters, it mounts next to the heater element, and it has been sized to fit right inside your bars. Install it and forget it. You will enjoy the automatic heat whenever you need it, and never again be distracted by chasing some elusive proper setting with rusty switches. FAQ Q: Do I need to set the temperature I want to run it at? A: No, that is pre-set at the factory (if by factory, you mean my laptop at the kitchen table). It automatically compensates for ambient temperature and wind chill. Q: So the grips will never be too cold? A: Well, these are still cartridge heaters. When you turn them on, it'll take a few minutes before they finally get warmth to your hands. Once they warm up though, they can hold a warm temperature up until you outstrip the total capacity of the heating cartridge (perhaps driving the bike into an arctic lake?). Q: So the grips will never be too hot? A: Again, these are still cartridge heaters. When you turn them on, that produces heat. But that heat takes a minute or more to get from the middle of the cartridge to where you can feel it. So while you are at 80 mph on a cold , the controller is sending a LOT of heat. If you suddenly come to a stop, the needed heat is much less, but the controller already sent heat that you won't feel for another minute or so. So yes, there is some overshoot. But the controller is already compensating for it within a few seconds of changing speeds or temperatures. In practice, it is nothing uncomfortable. In fact, its comforting to feel the controller working to do it's job. Q: How many do I need? A: One is plenty. It can easily handle the power of two cartridge heaters. It will only sense one grip, so if you have one hand off and one hand on the bars, only one of the two will stay at the right temperature, but this is an unusual situation and not uncomfortable. You could run one in each bar if you wanted though, and that would let you just run two wires to each side (instead of the normal three wires to one side, and two to the other). Q: So which side should I put it in? A: I recommend the clutch side (if you have a clutch). You actually hold this side more often than the throttle side if you figure in the time you spend stopped with the clutch in (where your right hand is probably taking a break). Q: What about warranty and indemnification? A: You know I am building each of these at a loss and out of my garage, right? You should probably assume I am trying to kill you and burn your bike to the ground and proceed accordingly. That being said, you should hook this up to a fused line, and one switched with the ignition, so you will be on the bike if it all starts to go horribly wrong. If so, the fuse will blow. If it doesn't, turn off the bike and cut the wires. I have a few thousand miles on prototypes with no problems (including a rolling stoppie that went bars first into the side of a moving Toyota Corolla) and have had absolutely no problems. Q: How much? A: Probably not much. Email me. The price will probably depend on if I have parts laying around, and to what degree I am in the mood to build more of them. It's about $10 worth of electronics, and maybe another $8 in consumables to make the board, and another $5 in wires and solder and shrink wrap. Since I do small volumes, I get clobbered by inbound shipping for parts as well. Then on top of that, even if I rush, its hard to build one of these out in less than 30 to 50 minutes (I have to cut and drill the boards, and solder everything up). Q: Can I build some myself? A: Sure! Post if you want to try, and I'll put together the Newark parts list, you can order the right bits direct from them. I'll post useful board layouts as well, you can wire it point to point from the schematic, or make your own boards. Q: What about the controller algorithms? A: I haven't decided. That's where I did most of my work. For sure I'll program a chip for you with my code for a REALLY cheap price. I'll probably open source the source before long anyway. So you can buy your own $20 programmer (link above) and I'll post you how to do it all. Q: How can we make this cheaper and easier? A: If we could get enough PC boards made, we could get them professionally fabricated. That's the part killing me right now. I'm guessing that would be $5 or so per board, and at least a $150 minimum order. Then I could just pack up kits with all the parts, a programmed chip, and a nice professional board, and you (or a buddy, or my boy scout) could solder them up. That would probably bring the "shipped" price around $30, and it would keep me from being a bottlneck no how this can scale. Q: Can we play? A: That sounds the most fun to me. That's the most appealing part of opening this thing up. This *exact* same hardware could do a LOT of really neat different things on a motorcycle. We would just need to change the code and hook it up different places. Talk me into it by showing me people are serious about really diving into it and learning. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Reepicheep |

Blake, it would probably work brilliantly for other heated gear. You would just have to mount it where it can feel the heat that the rider feels from the gear. I might have to change a few constants in the code though. I don't have any heated gear to test with it. I'm sure it would work great though, a heated vest is a MUCH easier problem to solve then the heated grip problem I started with. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Reepicheep |

Oh and Blake, you are thinking about it wrong. Think like the IPhone. You don't want to control the temperature because you want to control the temperature, you want to control it because the stupid heater is always doing the wrong thing whenever conditions change. There is one right temperature. That's the temperature you want. If the controller works, you never need or want to change it.  | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Blake |

So the temperature sensor is on the board, easy to make it remote? I think you already discussed via email making it work with heated grips by adjusting the programming. With a remote temperature sensor buried in the grip, would that be ideal? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Reepicheep |

You only have to adjust it when its wrong. Better to just never make it wrong, then you don't need to adjust it.  It could easily be remote, but that's two more wires to run, two more wires to break, and the packaging for the controller gets more complicated. For the external heated grips (Buell factory) it might work perfectly well as is, or it might need a tweak to one constant. (Message edited by reepicheep on October 28, 2011) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Reepicheep |

The three I sent out should be showing up soon... anybody hook one up yet? Blake, if you want to try one with the factory grips, I think I have a schematic around and can figure out how to hook it up. It would be only mildly invasive (the heated grip harness plugs into the accessory harness under the flyscreen, I think we would just have to make some minor cuts / taps into that). Just make sure you leave enough slack in the wire that you can pull the controller out of the bars, and replace the (socketed) IC. That way I can tweak the programming. Aaron S indicated he is willing to let his test bike be a lab rat, and he is local, so if I can scare up enough parts to finish the controllers I started (I had less inventory than I thought, but can probably scrounge from old prototypes), we may get to do some testing. I guess part of that depends on if it is broken in the first place. On the polly heaters, trying to find the right place on the switch is a pretty big distraction, and finding a place to mount the switch is a headache (at least on the S bikes). With the factory setup, maybe the lower thermal inertia of the external element grips and the convenient switch location make it a non problem (though I hate the hard plastic grips that you end up with... I like Al's soft enduro grips). | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Snoman |

I received the new controller last week and got it installed last night. I'd been using an earlier version that was mounted under the flyscreen before, so the install was easy. I used the existing polyheater wires to fish the new controller wires through the bars. I wasn't able to get the bike out today to try the heaters; hopefully I will before winter sets in. I'll be sure to report in after my next ride. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Reepicheep |

Cool! Let me know how it worked! Thanks Eric! | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bluzm2 |

Bill, I hooked mine up yesterday. Sent you a PM with info. Brad | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Reepicheep |

Smoking!  Just for anyone following at home, here is a lot of what I sent to Brad. His feedback was that once he hooked them up and rode for 10 minutes at 30 degrees, the grips were too hot to hold comfortably without gloves. We are working now to see if that is a feature, or a bug.  Here is most of what I sent him, but with some extra stuff added for context... For controller: Red wire to V+, black to Gnd. For Polly cartridge 1: Solder cartridge leads to two pads at other end of controller (polarity doesn't matter) For Polly cartridge 2: One wire to V+, the other to the yellow wire from the controller. Insulation on either side of Polly Cartridge 2. Insulation on far end of Polly cartridge 1, and red/black wire end of controller. Leave enough slack in the wire that you can get the controller far enough out the end of the bar to swap a chip or test if necessary. Tuck the extra wire under the flyscreen. And make sure the little bit of the end of the controller I didn't cover with the heat shrink tube (so you could solder to it) isn't shorting out somehow. I'd wrap it with electrical tape. At 30 degrees and speed, they should be right on the edge of uncomfortably hot on your palms while wearing golves, which puts them the right temperature for your fingers. Which I suppose probably would be too hot to hold comfortably without gloves, especially if you grabbed them right after coming to a stop. At that cold, the things are running very hot just to stay up with the wind chill. When you stop, they will spike hotter for maybe 30 to 60 seconds, because they pumped out heat (before you stopped) that you were going to need (if you kept going). They recognize overshoot instantly, but by the time they see it happening and cut the power, there is extra heat already in the system that needs to flow out, and I have no way to "drive it cooler". You just have to wait for it to bleed out. You have the opposite problem when you start up (not enough heat in the system for the new conditions), but it fixes faster, as I can drive it hotter on demand. If the cartridges aren't heating with the bike ignition on but motor not running, you probably have them hooked up right. You can check them as is using the little indicator light... just peek through the end of the bar and watch the light. Green means off, red means on. It is kind of a "pulse width modulation", so the ratio of red to green is the ratio of run to not run. At 30 degrees, it should start mostly red but with flashes of green. Once it comes up to temp it should be "whatever it takes" to hold that temp. If the bike isn't running, that indicator should still be cycling. Green is still off, amber means "I want to be running, but your stator isn't doing its thing right now, and I refuse to murder an innocent battery in cold blood". It is possible I screwed something up when I assembled the circuit as well. I "smoke tested" them on the bench to make sure they worked correctly, and that they seemed to be regulating (it was about 50 degrees in the garage and they started at about the right ratio of green to red that I expected). I didn't run them up in my test bed to see what temp they ended up regulating at. If I got a resistor in the wrong place, or shorted a trace soldering, they could be seeking the wrong temp. You could also test it by stuffing a thermometer in the end of the grip. I use a digital cooking one I got at Target for $8 or something. We can start gathering that data and use that to tune the controller for personal preferences. It only gets really smoking hot when things are pretty desperate out (like below 40 degrees or so, which on a bike at speed is nothing to be trifled with). On warmer days they are a lot more gentle, almost cozy. At 30 degrees, cartridge heaters have a pretty challenging operating envelope. They are trying to heat a cold metal bar, with a rubber grip over it, to go through gloves, to try and warm the riders fingers. It's a steep hill to climb, they have to get pretty hot. It's easy for me to change to make them run cooler... I can just send you a new chip to drop right in (it's socketed, just cut the heat shrink tubing over the chip and pry the old one out and push the new one in). So try it on an actual ride with gloves (bringing tools necessary to pull a fuse or cut a wire if it's going horribly wrong  ) and see what you think. ) and see what you think. I can reprogram a new chip and send it out if everything appears to be working OK but it's simply too hot. I was definitely tuning it towards the "too hot" end of the spectrum, and haven't tested much with kinder gentler settings... Now that I am getting consistently colder conditions here in Ohio I can try tweaking mine and see how it works. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Snoman |

I made it out last weekend and here's my report on the heaters / controller. It was a cool, cloudy day - started out in the high 30's, and ended in the low 30's. 300 miles running 95% open highway. There was a 15 mph side wind all day. I was wearing lightly insulated, waterproof Firstgear gloves. I let the bike warm up for around 10 minutes and while I could feel a little heat in the grips right away, it took a few minutes of riding before my hands started warming up. This may have just been because of a lack of power at idle or because the bike was still warm from being in the garage. Overall, I was very happy with the ability of the controller to properly adjust the heat output while I was at highway speed. I did find myself taking my hands off the grips or changing my hand position from time to time to cool my hands however. The pads of my palms right at the base of my fingers got really hot while my fingers were still cold. Grabbing the grips with just my fingers helped quite a bit. I don't think this is a controller issue however; it's characteristic of heated grips. Heated gloves would be better in this area, but I'm not sure they're the best total solution either. Since I was riding on-road, it was easy to move my hands around and help control the heating that way. If I would have been riding a dirt or gravel road, my grip on the bars would likely have been tighter and the heat spikes less tolerable. I've actually blistered my right hand because of this in the past. When slowing down and stopping in towns, the heat overshoot was noticeable, but I don't know that I have much of a problem with it. Just taking your hands off the grips for a bit cools both your hands and grips down to the point where everything is comfortable. I may sound critical of the new controller, but I actually think it works pretty well. While I was a little distracted by focusing on the performance of the controller on this ride, I think it's a more transparent option than a low-med-high switch would be. Before this latest controller, I was ready to install the '08+ RH switchblock with the heater switch. After this test ride, I'm less interested in going to a manual switch. I have a feeling the system will be much less quirky in temperatures above the 30's. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Reepicheep |

Thanks Eric! You are correct, once it gets up into the 40's the whole heater cartridge system gets nice and cozy, and the controller doesn't have to get too hot on the palms to just try and keep the fingers operating. Thanks for taking the time to post your thoughts. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Reepicheep |

OK, time to start publishing more information... Here is the parts list for the controller. This gives away a bit of secret sauce, just picking the right MOSFET was a trick in and of itself. That's worth several hours alone.

I'll review and update this table, this was just my last order, and it may not have had all the parts. Newark is as good as any other, and is just the one I deal with. Their web site is great for picking parts, their shipping is very quick and costs are fair, and their packaging is fantastic. Other vendors likely fine as well. (Message edited by reepicheep on November 17, 2011) (Message edited by reepicheep on November 17, 2011) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Reepicheep |

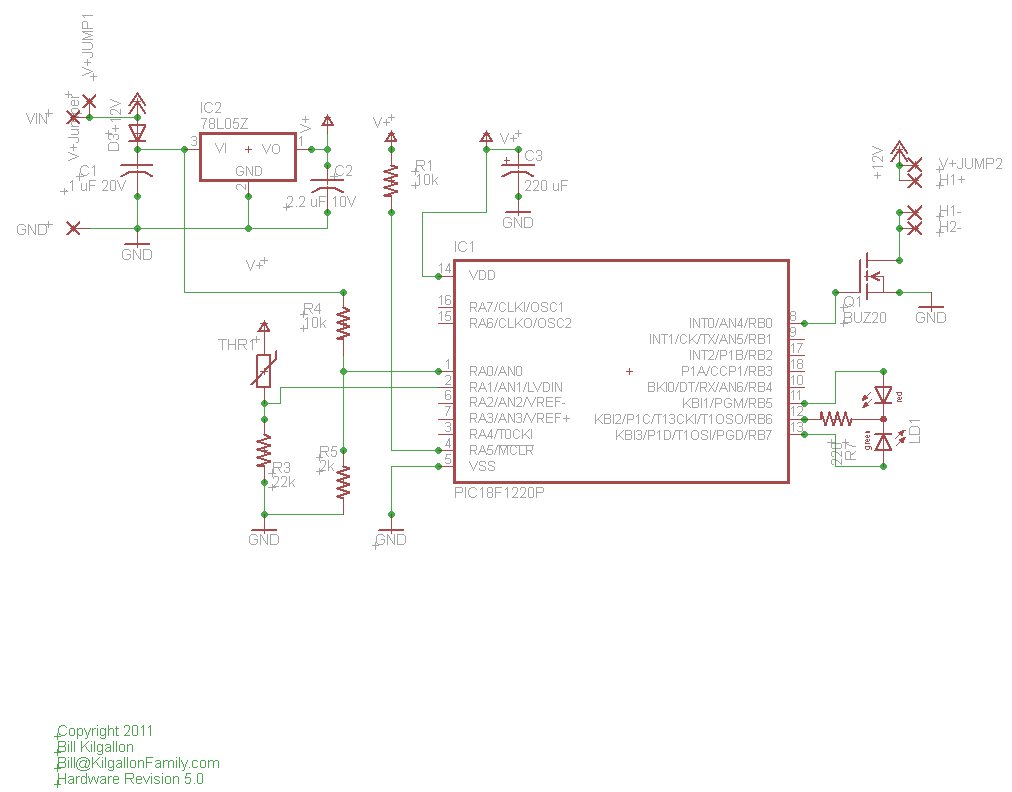

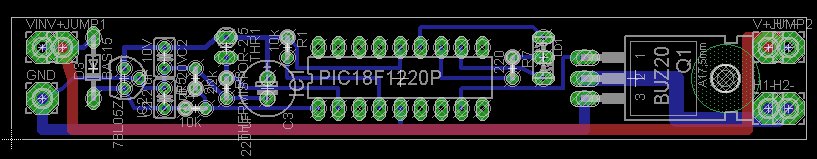

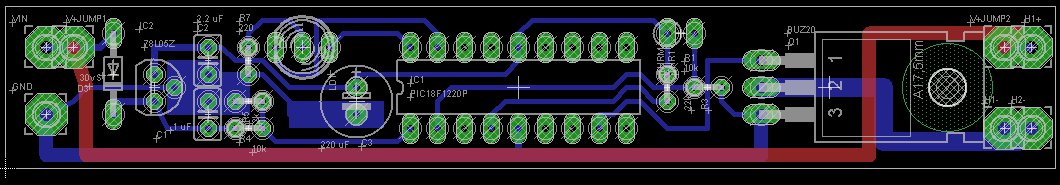

The PIC18F1220 is a great "slave" type controller, something that just does one thing forever and does it well.

It also supports an ICMP header (handy for prototyping, not for the board I designed). It can run with a completely internal oscillator (cool) if you can stand a 10% or so speed drift versus temperature (which we can here). It'll run at 40Mhz with an external oscillator, but is slower with the internal one... I forget how fast I could crank it up, I think it was something like 16 Mhz or something. Which is about 10x what I probably needed. It's dirt cheap, and a great chip to just have laying around for various projects. It has two shortcomings, both of which are "fixable" by spending more on a different (but similar) part. The first is limited RAM program space. 256 bytes doesn't sound like much, but it was enough for every version of this project that I came up with provided I wasn't being stupid. Much of your memory is actually program memory, the RAM is just needed for actual changing variables. You would want a different chip with more RAM and program memory if you were trying to do more than one or two things at once, or if you were doing something RAM intensive (like driving a graphical LCD). The other limitation is that the chip lacks a DAC. An ADC (Analog to Digital Converter) reads an analog voltage, and converts it to a number. This chip has a bunch of these. A DAC goes the other way, and you can put in a number, and get a corresponding voltage out. I can think of some times when this might be fun, but sure didn't need it for this project. For power consumption, the thing can run on nano-watts on standby. In operation, it's using less power than I can measure. Driving the LED's is the major draw of the circuit (minus the heating elements of course). The discrete outputs on the chip were really meant to drive logic gates, but they will put out just enough power to light up a low power LED properly. They can directly drive the gate on a MOSFET just fine, provided you spend about 3 hours digging up exactly the right MOSFET  . They could drive the gate on "any old MOSFET" if you introduced a second MOSFET or transistor, but I prided myself on keeping parts count on this circuit down to an almost impossible minimum. . They could drive the gate on "any old MOSFET" if you introduced a second MOSFET or transistor, but I prided myself on keeping parts count on this circuit down to an almost impossible minimum. I picked one with a USART for a reason as well, but I'm not telling why yet.  | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Reepicheep |

I should probably change the layout of that board and move the LED to the left, and the thermistor to the right. A lot of work, but routing PCB's is oddly satisfying to me. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Reepicheep |

Oh, and Eric, when you wrap your hands around the bars (like riding on gravel), it actually gets better, not worse. This is different than the Beta version controller you had, which definitely did this badly. This is a proper closed loop controller now, so the more you insulate the bars (with your gloved hands wrapping around them in this case), the less heat is being stripped by the passing air, and the less hot the cartridges have to run. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Blake |

How to install cartridge heaters on a Buell XB9R by the folks at Motorcycle.com. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Reepicheep |

Fun write up, thanks. With this controller setup, you don't need to futz with a switch (which is the real mounting hassle, and requires drilling holes in perfectly good motorcycles). That switch is where the wiring got complicated as well. You also don't need the 3 wire cartridges. This controller setup uses the 2 wire cartridges, and will have 3 wires into one bar, and 2 into the other (not 3 into each). $10 less and one less wire to fish. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Blake |

Send the guy one! I think if you could add a simple temperature selection control to set the heating level according to personal preference, you'll have a huge hit on your hands, and the folks at Poly, the heater cartridge used in the article would be eager to work with you. Based on feedback and experience with people, lol, a one size fits all firmware is going to be very tough to make work to everyone's satisfaction, but a simple adjustment capability would rock that. Could you do it? It wouldn't need to be a large range of adjustment, just something like 80% to 125% of your nominal setting? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Blake |

Really cool innovation Bill. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Reepicheep |

The adjustment is easy. Its where to put the knob that's hard. And then it just becomes one more distraction to putz with... we all run at 98.6, so there should is a "right" setting, there should be one that will work for everyone. I'll redesign the board to put the thermistor closer to the heating element. I think that will make a big difference with the extremes. I also am going to try putting an 15 watt resistor right on the board, all in a copper tube potted together. $.79 per resistor. So the heating element and controller are all one part. That will also make it work even better. The money saved on the heaters will pay for the parts for the second controller. And then you only need two wires into each bar. Maybe drop the LED also... it's cool, but it's only needed for initial install debugging... which would be easy enough to do with two test points on the board and a multi-meter. Here comes the real secret sauce ... I'm tired of trying to sell the design (which I didn't start out wanting to do anyway). The way I finally got this SOB to work was by just driving the regulator to a constant temp at the thermistor that is below body temperature. So when it's warm, the heater never runs. When it is colder, the heater runs hard enough to get the heat across the gap between the heating element and thermistor high enough that the thermistor hits the target temp. When the bike is moving, that gradient gets steeper, so more windchill effectively sets a higher cartridge temperature. What Eric (and I) are seeing at 30 deg and 70 MPH is an insanely steep temperature gradient. I actually find it reasonable... I would rather palms a bit hot but fingers warm when I need them, then comfy palms and numb fingers. It's uncomfortably warm on the palm at the same time it's uncomfortably cold on the backs of your hands, so there may not be a "right" setting. A shorter gradient would likely work better. The thermistor is where it is now because I didn't know if my MOSFET was going to be running hot when switching, so I put the thermistor far away from it. It doesn't, and if it did it wouldn't really matter, as the MOSFET is just another aspect of the heater element at the end of the day. So that was a mistake. I'll move the thermistor on the board. Anybody have recommendations for cheap practical potting compound? Something with reasonable ability to transfer heat? I'm thinking bathroom silicone caulk would be a good cheap option. Does it conduct heat? | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Blake |

>>> we all run at 98.6, so there should is a "right" setting, there should be one that will work for everyone. I forget, you're an darn engineer.  My time working in marketing humbled me and taught me much. Okay, it taught me much. ![: ]](http://www.badweatherbikers.com/buell/clipart/proud.gif) Entrepreneurship is a lot more challenging that people realize for sure. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Reepicheep |

I going to take the Steve Jobs approach and be a prick about trying to make it exactly like I think it should be.  I'll publish source soon, so somebody else can take on the Microsoft approach and become a millionaire by screwing up work done by somebody else.  | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Reepicheep |

That thermistor and LED didn't move without quite a fight. Now I have to change the code to match the pins I had to swap...  | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Bluzm2 |

Bill, About time I chimed in. I put the heaters and controller on my Uly for those that are following along. Like Snoman, I'm in MN, it is know to get a bit chilly up here this time of year. I commute to work everyday, lately it's been anywhere from the mid 40;s to the low-mid 20's. I too notice a lot of overshoot when slowing or at a stop light. There seems to be a temp right around 29-33 degrees where the controller gets a bit confused. The grips get HOT! Above or below that window the controller works great. I rode home last night from work at about 7:30, it had dropped to about 24 degrees, I was very grateful for the extra heat. Earlier this week when it was in the low mid 30's my hands were almost too hot. I'm still trying to make better mental notes about temp vs grip heat. Like Bill has said a number of times, heat loss when moving is a tough one to compensate for. I'm wearing Tourmaster winter gloves, they are leather front and back with a fair amount of Thinsulate. I'm still looking for the perfect winter glove. I wondering if the Olympia model that has heavier Thinsulate on the back of the hand and thinner on the palm and finger bottoms might be the way to go with heated grips. I think I'll pick up a set and give them a try. Problem is, with the thinner palm/finger, the too much heat thing might really be too much.. The gloves are about $60, well worth a try. I might not get a chance to try it this year as I'm gone for a week after Thanksgiving. It will probably snow for good while I'm gone. The fingertip deal that Snoman mentioned above has also been noticed. But,, I also noticed the same thing with the Heat Demons on my S2. So far I like the Poly Heaters and Reep Controller much better. Bill, a couple of thoughts. I too thought the thermistor might work a bit better on the other side. That would put it closer to the heater and maybe lessen overshoot. Another thought is to monitor voltage (you are already doing this on startup). When the voltage starts to drop off (like when you are slowing to stop) you could cut the heat based on input voltage instead of a straight voltage change across the thermistor. This might shorten up the lag period. Now if I can just keep my damn face shield from fogging... Brad | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sparky |

"Now if I can just keep my damn face shield from fogging " Maybe it needs a heater...  , Bill? , Bill? |