| Author | Message | ||

Tempest766 |

So before I had the actual XB series service manual I tried to remove the oil feeder line from the bottom of the oil pump in preparation for switching the muffler back to the stock one. I saw a bit too much oil dripping for my taste so I attempted to reinstall the oil line fitting back into the oil pump but stripped the threads in the oil pump housing pretty badly. I now know from the service manual that there is a tool to unload the spring holding the flanged oil hose into the fitting and that removing the fitting from the oil pump is not the thing to do. Anyway, after over a week at the HD dealer they finally call me and tell me that they cannot tap and rethread the oil pump housing and want to install a whole new housing, which requires rotating the engine and many hours of labor...bottom line: I'm looking at about $800 for something that should be able to be performed with a simple retap of the housing. What are my options? I'm having trouble believing that the thing cannot be retapped and am wondering if they are just saying that out of 1) not wishing to go that route, and 2) looking at a much larger service bill Are there other substances similar to sealing tape that can make up the gap in the stripped threads and properly seal the thing and not shake loose from engine vibration? Any thoughts about some sort of setting rubber sealant similar to thread sealer but appropriate to fill the gaps in the bad threads? | ||

Ted |

no specific advise, but i dont see a down side to heli-coil it. its obviously a diff setup than a 04xb9. i've tried 4 times to fix a fitting leak on mine. next attempt is with teflon tape ..! | ||

Rcontroler |

Ted, where is the leak on yours? I had a recurring leak on my '03 xb9s that I repaired a while back. | ||

Tempest766 |

the HD shop tried to tape the hell out of the fitting to get me on the road while they are ordering the oil pump housing but said any vibration from the engine still allowed it to leak. They say the reason they cannot use a traditional retap is because the fitting it tapered and bottoms out on a lip inside the housing. I'm pretty sick over the whole thing and as an electromechanical engineer myself, I'm beginning to question the engineering and design specs of these Buell bikes. There ought to be a law: The manufacturer shall always place hardened steel inserts into all aluminum component threaded receptacles. | ||

Spdkls |

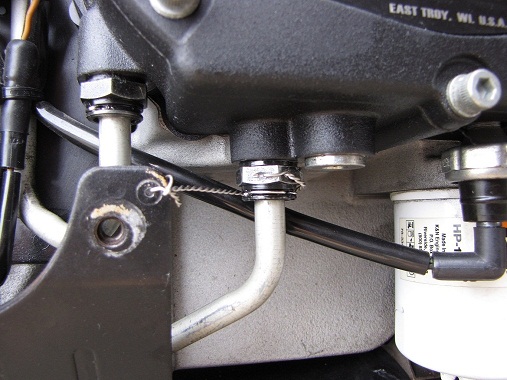

I am having the same problem. Couple of questions before I do something drastic. 1). What about using thread sealant and safety wire(lock wire) to hold the fitting tight? 2). What about using a different type of fitting(brass, aluminum) cut the existing fitting off, then using a flare tool and slice in an AN setup. 3) Cut the line in a safe place, use steel lined rubber hoses, and TIG weld the original fitting to the housing? | ||

Spdkls |

So this is my temporary/permanent fix. Definitely won't vibrate loose anymore, just hope that its tight enough to stop leaking.  |