| Author | Message | ||

Henrik |

Machine screw sizes: I'm looking for replacement fasteners (bolt and nut), non-stock items, and am having trouble understanding the different sizes available. I've measured the bolt in question, a 5/32", 36 thread pitch 1/2" long bolt. McMaster doesn't have such a beast, but has some #8-32 screws instead. From the tech drawing it looks to be just a tad bigger diameter, but should otherwise work?? Any suggestions? Web links explaining the different sizing standards? Henrik | ||

Lake_Bueller |

HELP!! This looks like as good of a place for this question as any other..... I'm in the process of putting the final touches on a rocker box gasket fix. The problem I'm having is with the old fiber washers on the upper bolts. They seem to have become one with the upper rocker box cover. Anyone have a good solution for removing them w/o scraping? I've tried WD40 and soaking in water. They seem to be baked on the cover. Thanks for any available input! | ||

Blake |

Without scraping? Try gasket remover/solvent or MEK (methylethylketone). Immerse the cover in carburetor cleaner/acid. If you are worried about cosmetic damage, try scraping with a hard plastic/nylon knife or such. Or scrape with a sharpened screwdriver blade and polish out any exposed scratches. | ||

Bomber |

ALL . . . . . in my locaql hardware store (which has, say hooray, a fairly decent selection of metric fasteners), most are listed without reference to a grade . . . . some, however, are listed as Grade 8.8 (if memory serves) . . . . is this an idication of a harder faster? thanks | ||

Rempss |

The scale indicates a stronger fastener. Metric Grade 8.8 is equal to Grade 5 inch size. About 120,000 PSI tensile strength. Use discretion when replacing any factory fastener with another type. Is the fastener itself marked 8.8 or does the store let you know this? Beware of fasteners that are not marked with strength and manufacturer. Jeff | ||

Bomber |

Thanks Jeff . . . the fasteners ARE marked (although I know that's not a sure thing either) . . . sheesh, if Grade 8.8 = inch Grade 5, I wonder what the un-marked fasteners are made our off . . . pasta? | ||

Blake |

Grade 5 is classified as a high strength fastener, good stuff. | ||

Bomber |

Blake . . . . yessir, 5 is good, but if I were replacing the fork brace fasteners (for intstance, please don't ask why ((grin))), I'd go as hgih as I could go in terms of grade . . . any chassis stuff I probobly err on the side of higher-than-necessary grades . . . 8.8 is likely fine for this application, but if it were an inch size, I'd probobly go high (belt and suspenders both, I spose) | ||

Rempss |

Metric is available in higher strength also; Grade 10.9 & 12.9 are quite common, if you feel the need. I replaced some of the high strength cap screws that were originally Grade 8 (all inch cap screws I have found are Grade 8 or better) from the factory with standard stainless; about Grade 2. Just depends on the joint and materials used. Jeff | ||

Blake |

Bomber, You might consider what you are threading those grade 8 bolts into.  BTW, You can tell the grade of a Hex head bolt and most cap screws by their markings. See page 5 of this online reference. More good online info about threaded fasteners. and more info even.  | ||

Bomber |

Blake . . .. . yessir, right your are , , , , ,grade 8s into aluminum IS silly . . .it would be sillier is I torqued em to the capacity of the bolt (or tried to {grin}) thanks for the sites, Blake . . . . .2 were brand new (I love learning stuff, even if I don't understand it . . . .now, back to the cooling efffect of evaporating fuel . . . . .. .. ) | ||

Boyle |

Hi guy's,new to the Buell scene. I have an X1 of a 2001 vintage that keeps breaking the engine mounting bolts, they break inside the head, about 10mm in. Is there any other type of bolt that I can use, what about stainless. Any advice. | ||

Mikej |

Find the cause first instead of finding a stronger bolt or you may be breaking something more than a bolt. You may have an alignment issue with the mount joints, or some other issue that is causing the bolts to break. What has been done to the bike, how is it ridden, how were the replaced bolts installed? More questions than answers, but your answers may lead someone to give you a more valid response. | ||

Hootowl |

What Mike said. That should not be happening. You are using the CORRECT factory bolts right? Your front isolator may be shot and placing a lot of instantaneous shear loads on those bolts. If your hemi bars have been moved from their factory positions, that'll screw things up too. Also, I would not use stainless bolts. Not in aluminum heads. You can use some permatex to stop the corrosion, but that will mess up your torque values. I'm not sure what goes on those bolts i.e. locktite or nothing at all. Hope this helps. | ||

Boyle |

Thanks for the info guy's. The alignment thing could be a goer anyone out there have the procedure for re-doing this or checking it.How do you know if the front isolator is shot? Open to all sujestions. At the moe the bike is parked up for winter, abit icy down here at this time of year a real bummer. | ||

Vr1203 |

Aluminum 7000 series socket head cap screws in 1/4X20 as in primary covers and the like.I'm looking for a source for the ProBolt style aluminum bolts(but in NC not metric) to replace some of the hardware on my bike. does anyone have any ideas? | ||

Vr1203 |

No one has a lead on aluminum bolts? | ||

Peter |

Jim, Type "aluminum bolts" in Google. 1st hit.... http://www.racebolt.com/misc.htm | ||

Vr1203 |

Peter,Thanks for helping ,but, unless there is something more on that site that I don't see, they don't cover the lengths used in the primary and I think their bolts are hex head.  It kind of peas me off,I used real nice anodized aluminum socket heads on my Ducati(metric),no problem.But I can't find any NC  | ||

Jprovo |

Vr, I don't see any readily available, but I'll check the aerospace stuff to see it there isn't something out there. So far, no dice with the catalogs that I've got lying around near my desk. Of course, on all the blind hole stuff, you can go with through drilled stainless, available through McMaster-Carr. James | ||

Vr1203 |

I've found an outfit that will make them. Expensive.If alot of people would like go into this, he needs a miminum order of 50 pc's for each size in one color only. As an example, 1/4X20 by 2 1/4" socket head caps would be $2.50 each. | ||

Peter |

Jim, What colour do you want? | ||

Vr1203 |

Peter, I was going to get them in a silver /natural anodized finish. Or maybe black,if it was available. | ||

Peter |

I'd be interested in a set of natural anodized ones. | ||

Jim_witt |

Jim asked: No one has a lead on aluminum bolts? Jim, just curious, what are these pup(s) for anyway? Haven't a clue what you're looking for either. Have a picture? -JW:>  | ||

Vr1203 |

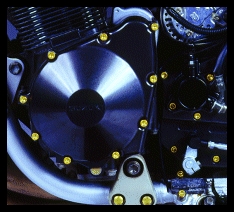

Jim W. I need them to replace the steel bolting on the primary,timing and rocker covers. Maybe more.   | ||

Vr1203 |

Peter,I think we could order maybe 60 pc's,in 2 1/4", and cover all the 1/4X20 bolts on both bikes. We would have cut down the bolts to length for the shorter ones. They would have to be fully threaded.  | ||

Jim_witt |

Humm ...... what am I missing here ...... am I like a dumb shit or something ...... why do they have to be aluminum? -JW:>  | ||

Peter |

Jim, Actually I'd be more interested in if I could buy them with no thread cut. Then I could make them whatever length I wanted, and still have the unthreaded portion. I'd only be losing the anodizing on the thread, but I use anti-sieze on all those bolts anyway. Will he sell them like that? Should be cheaper too. Jim W, Don't be silly. It's to save weight  Nothing at all to do with being 'trick' or looking cool...... | ||

Vr1203 |

Peter,I'm sure they would do that. But their threads would be better than yours(or mine). And the weakest part of the bolt is the minor dia. ,so fully threaded should be the same strength. |