| Author | Message | ||

Buell_bert |

Has anyone made a shock extension to lower the rear end? If you could extend it 1-2 in. (move it back)it would make a difference for shorter riders. And I do not worry about another rider. For now I may try the newer frt. brkt. and use the older shock and measure before and after. I already have the low seat. I just don't like not having both feet flat on the ground when stopped. And no I do not want to buy another bike. I'm 5-8 and 170 lbs. I must just have short legs. I also do not want to remove any more padding in the seat. If the brkt./shock work I may just make/machine an aluminum brkt. to work with my newer style shorter shock. Well thanks for any ideas. | ||

S2pengy |

Yes, I done it...What do you want to know and do you have access to a welder or machine shop... | ||

Buell_bert |

You betcha I'ld like to know. And I have a welder and a mill/lathe. Thanks | ||

Maxbuell |

I am wanting to make something as well. Need to look into it. I know they sell a bracket but its crazy like $300 or so. | ||

S2pengy |

Two ways you can go 1. Using the front shock mount you already have, weld and then redrill the lower of the 2 case mounting holes pushing the mount aft. This offsets the hole about a 1/2 inch and lowers the bike about 1 1/2 inches. It may cause belt to beltguard interference and requires a new hole for the shock reservoir mount bolt. I am using this with a WP shock and the older front shock mount which is not a casting so it doesn't have the webbing in the casting.. 2. Male/female adapter installed between the shock and front shock mount which effectively lenghtens the shock lowering the bike.. Problem is it has to be as short as possible and as strong as possible.. The way I use it is with the older front shock mount (which doesn't curve aft) and the latest showa shock and the adapter inbetween, this gives enough room for the male/female adapter. If to long it will cause all kinds of rear belt interference.. Also keep in mind the mount bolts for the shock are metric so hole sizes and bolts become an issue, as well as bolt strenght... You also have to be creative with the shock reservoir mounting as well... Please be careful doing any of these mods because your life can depend on it..... I am presently using one of each method on my S2's This is the basic info any other questions fire away... | ||

Buellfart |

how about cutting shock eye off old steel swingarm-a little careful cutting and crunching in a vise-drill new holes,as close as possible.thinking of doing this,already have part cut-how far apart holes to drop 2-3 inches? | ||

Buellgrrrl |

Is this a standard M2 or the factory lowered M2L? If it's a standard I'd suggest trading for an M2L or at least the suspension off an M2L instead of reinventing the wheel. | ||

Buellfart |

P.s.sure wish somone could post a pic of one of theses front shock mounts. | ||

Buell_bert |

I thought there were pic's of a modified frt. shock mount here before? It really looked like a good idea. | ||

Rsrss |

Comparing our '02 M2L front shock mount to our '00 standard M2 it appears that the M2L front mount moves the front shock eye to the rear approx. 2". This would be a quick and simple way of lowering, if it is practical. | ||

Maxbuell |

Bert, There is a pic floating around here some where. From what I remember 3/8" will lower the rear end 1". So if you weld tabs on to the lower part of the front shock mount and redrill new mount hole 3/8" should give you 1" lower. Plan on doing this soon as well. Have been looking for a spare front bracket in case I mess it up. | ||

Bad_karma |

Matt Just saw one on ebay. Joe | ||

Big_koch |

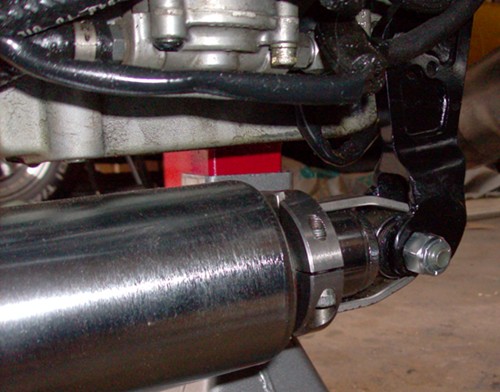

Just re-did the bracket to lower my 2000 M2 about 1.5" The pivot-to-shock lever is about 8.5" and the pivot-to-axle lever is about 16" on mine, so 3/4" rearward at the shock roughly doubled at the axle... about 1.5" lower.       | ||

Buellfart |

I like that safety,backup thingy,except that it looks like it could slip off in a pinch; also I think it would be good to weld on some kind of,descreet looking fork do-hicky that reaches up and could grab the bottom of the shock bracket fork stem if the bolt should break (also would apply torque to assemblage thus resisting slippage).No engineer me,always think worst case scenario.Great pics,thanks | ||

Blake |

Tyler (BK), It looks like the gap between the two modified lugs is significantly greater than it was for the original configuration. Increasing that gap will increase the pin-bending stresses in the bolt by a huge factor, thus increasing the risk of a fatigue fracture in the bolt. Washers to fill the gap won't help. If that bolt fails, your added retention strap won't help anything. Please be careful. (Message edited by blake on April 22, 2008) | ||

Big_koch |

The gap is just under 1 cm wider b/c the new is welded to the outside of the old. I also increased the size of the bolt used so it was a standard instead of metric. There isn't anything "added" to the shock...it's the same way I got it. The larger diameter grade 5 bolt should be more than adequate to deal with the slight (or significant) increase in distance. If not...I guess I'll learn the hard way. Considering switching to a compression shock with the new swingarm I'm fabbing up so it may not ever see the road. (Message edited by big koch on April 22, 2008) | ||

Blake |

I'd hate to see you learn the hard way, as that is a seriously life threatening lesson. Do yourself a huge favor and if you do decide to keep the bolt in bending, keep and eye on it and replace that bolt once every year or even more often. It's also advisable to keep any of the threads out of the shear plane (where shock eye meets lugs). One more thing you can check on.  Stress/structural analysis is my professional trade going on for twenty years now. I'm not pulling your leg or trying to scare you. I can tell you that I personally wouldn't run the shock that way. It just doesn't take much stress compared to the normal static strength of the bolt to instigate fatigue crack growth. | ||

Buellfart |

On second thought,unless that bolt has a history of failure,at gut level,it should be ok though I'd check it occasionally for all above reasons-That strap kind of freaked me out,as if you had some serious doubts,not that they may not be warranted. It's basically a very similar bracket but no engineer,me. | ||

Buellfart |

sorry,I just had another brain fart-connect that "strap" to some kind of heavy/duty eyebolt/cable then attach that to the front shock mount-at least you'd have enough time to pull over if a big truck was hot your tail in a windy,hail storm.OK,enough said,on my part.I'm a worrier. | ||

Big_koch |

Yeah...If I wanted to it wouldn't take too much to cut another thickness of steel and weld that to the inside so the bracket was the same gap, but with the bigger bolt also (stronger than stock), but my mind is completely at ease with this set-up. If it was a rigid rod instead of the shock I'd worry a bit more. This thing gets torn apart so often the bolt will probably get checked every 6 months or more, and the nylock nut replaced every time. My background until the M2 has been with choppers so I've learned a small something about stress, work hardening, triangulation, weld penetration, etc... Don't worry about the threads. Already knew the weakest point of a bolt is where the threads meet the shoulder. Made sure the shoulder was all the way across the bracket so it didn't want to shear there on me. | ||

Djkaplan |

Don't let the bolt spin in the mount. It'll wear the holes until the intact bolt just pulls through the mount. | ||

Big_koch |

It's not. It won't. | ||

Bluelightning |

Out of curiosity, wouldn't it have accomplished the same thing, since you are using the older, longer Showa to just use the newer shorter showa stock bracket? The newer bracket already has the bend and moves the mounting point rearward some to make up the shorter shock length. Just a thought..... | ||

Big_koch |

I think the difference in shock length is about 2", which would've translated into a 4" drop. Not at all the same thing...not even rideable at that point. I'd rather modify what I already have to work as I want than spend money I don't need to for a bolt-on. |