| Author | Message | ||

Rocketman |

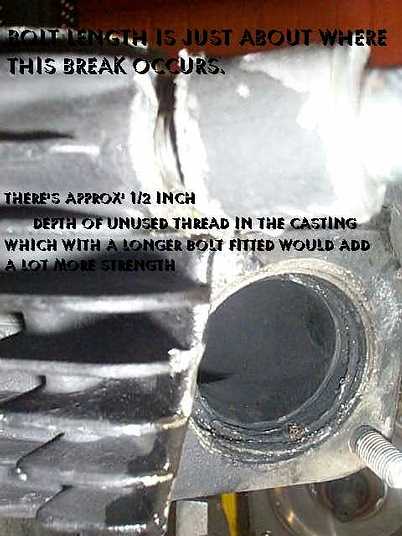

The problem is very simple I believe. The right side bolt is carrying far to much weight\load. Remember, on a Sportster the front mounts are designed for a head steady and not an engine mount. The way I see it is three fold...... 1st The design was not meant for the purpose. However, I don't believe this is the real problem and I'm sure it CAN work perfect with the correct length bolt. 2nd The right side threaded hole is not a suitable casting. It sort of sticks out from the rest of the head (casting) which must make it weak for load bearing, and the casting is full of tiny floors. Maybe with the correct length bolt fitted, the head casting would be able to cope with the stresses involved. 3rd The bolts are #8 strength if I remember correctly, which should be well strong enough, but, as the bolts are 'bought in' rather than specially made items for the purpose, they are short in the threaded section. As far as I can find out, no one makes a suitable length bolt which probably explains why the bolts are to short in the first place. When fully torqued the threaded end of the bolt stops right at the point the threaded hole spouts off the main head casting thus acting as a cantilever. There's still a good 1/2 inch of thread left in that hole that doesn't get used and more importantly, the leftover thread is actually 'in' the head casting rather than spouting off it. This is exactly the place where mine snapped off, both head casting and bolt. If I saw a bolt that had broken off inside the hole I'd be very cautious about the integrity of the casting itself if it hadn't already broken. Solution, weld all around the casting of the right side hole, making a good and meaty fill of alloy weld, then have a longer bolt made with approximately 1/2 inch more threaded length added on. Rocket in England | ||

V2win |

I figure that hole in the head, the broken bolt came out of, is a little like an old girlfriend of mine. Has anyone tried installing a helicoil in the head? I have not had a chance to look at it yet and dont know if there is enough material to do so, but it would seem to me a good thing if it can be done. I plan on taking a close look at it tomorrow. | ||

V2win |

Also, Why use a bolt at all? Why not use a stud that could be screwed in all the way with a nut on the outside.Perhaps the hole in the mount would have to be a little larger and a steel collar pressed in so the threads of the stud dont eat up the aluminum. Hmmmmm. | ||

Ralph |

Blake, that's a fantastic explanation for whats going on. Had to go make myself a peanut butter sandwich just to try it. Mmmmm, crunchy. bighairyralph | ||

Blake |

V2win: I'd be REAL skeptical of using a helicoil in an application requiring a high strength bolt. The helicoil will only further weaken the supporting aluminum. You'd be far better off just going oversize if you have to and retapping the hole. Rocket, It seems we have differing failure modes. Yours would certainly seem to be helped by a longer bolt/stud. BHR: "Wet noodles" and "peanut butter" are two of my favorite stress weenie analogies when explaining the flaws of a draft structural design with junior engineers. "Spaghetti" came up once in a while also. And the ever laudable "beefy." Dang, I'm hungry!  | ||

Steveshakeshaft |

[quote] Watch out for those crack heads!!! Steve, I was only answering V2win's question. Sounds like you have other issues similar to Rocket's. Are the three failures in your group on stock engines? [unquote] Yes, they are standard. One X1 has two bolt failures in 6 months. Another X1 has a cracked head. There are a number of things going on here, perhaps more than meets the first look. But the fact that there are different failure modes around the same system suggests to me that the sub assembly is of marginal design for its purpose? I have considered myself using a stud/washer/nut combination, but I think it would be a devil to assemble? Steve steve@ukbeg.com http://ukbeg.com | ||

Blake |

Steve: One bike, two failures... hmmmm makes you wonder if maybe some type of squizishness might be involved. I'd be surprised to see such failures if the heads were NEVER removed, and the bikes were never mistreated or significantly hopped up. The engine mount in question is definitely a failure point. When I crashed my first '97 M2, letting it cartwheel at 70 mph, it ended up with a broken front engine mount. Of course the front axle was SNAPPED IN TWO as well. Wouldn't you agree that we should first look elsewhere for causation rather than be too quick to point a blaming finger at Buell's design integrity? | ||

Steveshakeshaft |

Blake, In principle yes. I agree. I don't question that the design might "generally" be fit for purpose. Many folks will likely ride 70000 miles and never have trouble. I suspect I might be one of them, never ride too quick, never have less than 2 wheels on the floor and so on. There are several users on our group who have had more than one failure in this area. Possibly they have different habits to myself? I don't know. In my line of work (not motorcycles, but "machines" none the less) I see many "adequate" designs tipped over the edge by circumstances. Sometimes not even circumstances that come to light until you have full grasp of ALL the details. Yes? Unfortunately, I am not in the position of seeing and evaluating these breakages for myself (much as I'd like to!). I'm just adding to the "knowledge" here! If I can help to eliminate a problem by throwing some of that "knowledge" in the pot and cooking it up a little, then great eh? Steve steve@ukbeg.com http://ukbeg.com | ||

Rocketman |

Firstly, let me say that I'm not pointing the finger at anyone but the design is questionable never the less. I forgot to mention the other day that the original mounting bracket is NOT flush across the bolt holes. When I made the temporary repair I had to take up space from the bracket to the head using a couple of suitable thickness washers. However, this problem should be rectified for all because the new style bracket and bolts are meant to be an improvement on the previous design. Me, I'm installing the X1 mount so I need not chop off the breadbox mounting !  Rocket in England | ||

Sparky |

After 78k+ miles the front motor mount broke on the S1 & the left bolt snapped flush in the head. Fortunately I was able to continue riding to work & get the bike to the dealer after I reassured myself that the motor wouldn't fall out and send me tumbling on the freeway. So, Kudos to Bartels' for extracting the broken bolt without removing the head, getting the correct mount & airbox support bracket ordered and installed in less than 2 weeks. Steve the Svc Writer & Kurt the Buell tech know their stuff & deserve a round of applause. A long time ago the selling dealer (LA) replaced the stock beefy motor mount for the thin Vee shaped mount of the 97, 98's. Why? I don't know. The bike was in for other recalls &, I guess, they thought it needed this one too (it didn't). Anyway, it's got the beefy stock triangular mount again.  And ya know what? It sorta looks like a Firebolt mount! And ya know what? It sorta looks like a Firebolt mount!  Sparky 96S1, 98S3, XB9R | ||

Steveshakeshaft |

These failures continue to happen. Last week one of our members had the outer bolt fail flush with the head on a '00 model year M2. Mickey Burke (Eyeball Engineering) makes very nice polished stainless steel engine mounts, however, I'm sceptical. Making the mount stronger might just lead to more head failures? Steve steve@ukbeg.com www.ukbeg.com | ||

Ct_bob |

Add my 1999 S3T to the list of failures. Broken bolt in the left hole. Broken inside the head about 3 threads. Right bolt was loose and from the damage to the head and mount it looks like either the right was loose for a long time or the left was broken. The weird thing was the broken bolt head was still sitting in the mount, very loose. Mount and head is costing me $305. I will do the work myself as I have had bad luck with dealers. My first indication that there might have been a problem was the rear tire was severely worn on one side. I am a modest driver and never push the bike hard. | ||

S3dave |

Another S3 with a broken motor mount bolt (2000 w/ 36,000 kms)..left side. Noticed that the bolt head was missing, must have caught it as soon as it happened, as no damge to the other side or the mount. I did have to ride it home, about 450 kms, but things went O.K. Supported the bike, removed the front end and the motor mount. Drilled out the bolt so I could get an easy out in it, pulled the broken bolt. I am replacing the other bolt also and I am using grade 8 bolts as the L9s will have to come from the dealer. I will just be checking this whenever I service the bike and probably replace the bolts every now and then. | ||

Rustyx1w |

My X1W broke the casting on the long side, almost 1/2 way between the hang point and the cylinder bolt, the other side bolt snapped off even with the head. So I have to drill it out,a buddy of mine has a 90 deg air drill I can use, otherwise I would probably have to take the head off and get the bolt piece out. I don't do wheelies, mainly commute to work on freeway and city streets here in KC which are rough as a cobb. I think I hit a manhole cover divot and did this. It felt like a washing machine out of balance when it happened. The things that •••• me off the most is the broken piece gouged the rocker cover, uglied it up real good, so much for trying to keep this bike looking good and right now I am strapped for money and have been riding the bike to work to save on gas expenses. The bike also keeps me from sitting in traffic jams breathing exhaust fumes and overheating my truck by allowing me to get the hell out of the way or turn around and go the other way if I need to. Worst | ||

Al_lighton |

It happened on my S3. The left bolt breaks and then the motor is hanging by the right bolt for a while until it either breaks the mount or the right boss snaps off the cylinder head. Not good. I check to ensure that left bolt head is there as part of my normal preflight any more. To fix it, go to Mcmaster Carr and get the right type of easy-out..use a multi-spline extractor as shown 2nd from the bottom of this page: 2674&sesnextrep=336440542105952&ScreenWidth=1152&McMMainWidth=823,http://www.mcm aster.com/asp/DisplCtlgPage.asp?ReqTyp=CATALOG&CtlgPgNbr=2673&CtlgEdition=&Relat edCtlgPgs=2673,2674&sesnextrep=336440542105952&ScreenWidth=1152&McMMainWidth=823 And get a left handed cobalt bit from them too: http://www.mcmaster.com/param/asp/psearch.asp?FAM=metaldrills&FT_320=38378&FT_52 3=38181&FT_775=38131&FT_780=38161&FT_781=38764&FT_783=38898&FT_785=38164&desc=Le ft%2DHand+Cobal t+Steel+Drill+Bit]http://www.mcmaster.com/param/asp/psearch.asp?FAM=metaldrills& FT_320=38378&FT_523=38181&FT_775=38131&FT_780=38161&FT_781=38764&FT_783=38898&FT _785=38164&desc=Left %2DHand+Cobalt+Steel+Drill+Bit I bought a small pilot cobalt drill and one that was the right size for the easy out. I drilled the small hole first (using an assistant to help maintain alignment). Drill the pilot hole, then torch it for a few minutes to melt the loctite, then drill the correct hole. I was amazed how well that cobalt bit made easy work of that grade 9 bolt. You may actually get the bolt to start coming out with the left hand drilling, but likely not. But that multi-spline easy out will remove it easily and won't snap off in the bolt like a home depot extractor is GUARANTEED to. Be sure to follow the B-018 service bulletin installation procedures to the letter, using NEW bolts and washers. All in all, not too tough a job with the right tools. I took the front wheel and fender off to get the drill clearance, that was the hardest part of the job. If it ever happens again, it's getting a Nallin mount. The stock mount is a weak spot in the design, there must be some funky resonance going on in that left mount arm that is causing that bolt to break. The dynamic loads alone can't be enough to do it. The nallin mount has the web that joins both arms. Al | ||

Dave |

Perhaps a more important question... What is proverbial ounce of prevention for this? Install new bolts every 10k? Ideas? DAve | ||

Al_lighton |

Well, a few weeks ago, I went to jump on the trusty S3 and noticed the RIGHT front engine mount bolt head missing. Poke something in there, and sure enough, the bolt has sheared flush with the head. Bummer, I just fixed the other one only 6 months ago, and had replaced both bolts. Yesterday, I went to fix it, and when I went to remove the left side bolt, low and behold, it was broken as well, about three threads in. It was merely finger tight as a result. My entire motor was hanging on three loose threads. I'm sure if I had not noticed that left side bolt missing, it wouldn't have made it 5 miles. I installed new bolts (per the B-018 procedure, as before) and a Nallin Motor Mount. The job really isn't too tough if you have the drills, the right extractor, and a torch to melt the loctite. You don't even need to remove the front wheel, but it does help to remove the fender bolts and let it sit on top of the tire for additional drill clearance. Seeing that RIGHT bolt failed made me doubt my theory that the LEFT side mount/bolt is seeng some resonance that causes the left bolt to fail, then the right side mount or head fails because it is carrying all the load. Finding the right side bolt broken too reassures me that in fact, there is something going on there. One question: has anyone had this failure WITHOUT the top Heim joint fitted? My S1W doesn't have that heim joint, it hasn't had this problem. The top Heim joint attached to the right side of that mount....Hmmmm. Pre-flight all tube frame bikes, always check for two bolts there. May save your butt some day. Al (Message edited by al_lighton on October 18, 2004) | ||

Jusask |

It happened to me today ...... 00 S3T ....bike started shaking REAL BAD ..(I was accelerating mildly and had reached about 45)... stopped and the left bolt sheared off and the front motor mount BROKE IN HALF. Not sure if the bolt broke today (must've as it was still in the mount when I stopped). Fortunately the Harley Dealer (Sauk-Prairie) was about 20 mi away ..... they sent a truck and picked me up ........ $386.61 and 4 hours later .... I was riding again ..... BUT THAT SUCKS !!!!!! One of the techs guessed that maybe it's because we run at low rpm's to much and the vibration takes it toll ..... Huh? Does this sound possible? And, the tech that worked on it said he had never seen it before ...... now I find that incredible !!!! Was there ever a recall or tech advisory on these things? | ||

Buellistic |

My personal "OPINION" is these front motor mount blots are being installed WRONG !!! WHATS IN THE MOTOR MANUAL is all WRONG EXCEPT for the TORQUE SPEC's !!! THE SAME APPLIES TO THE "EXHAUST SYSTEM" !!! "ALSO" "ONE OF THE MOST DANGEROUS THINGS IN THE WORLD IS A HARLEY-DAVIDSON TECHNICIAN WORKING ON A BUELL !!!" In BUELLing LaFayette (Message edited by buellistic on September 30, 2005) (Message edited by buellistic on September 30, 2005) | ||

Doncasto |

Terry: There have been, by my own biased and subjective count, dozens of failures related to these bolts breaking. There are as many or more opinions as to why they continue to break. My own opinion is that when Buell entered into its profit enhanced design changes in 1997 they took some shortcuts. Hanging the front of the engine on a less strong and less substantial bracket was one of them. It is also my opinion that someone at Buell must have suggested at some point that in order to use a Sportster engine - designed to be installed in a full wrap around frame supported from its underside, and then hanging the engine by its heads on the Buell - a sturdier head bolt, and sturdier front head mount would be desirable. IMHO, they got away with using the unimproved Sportster head and bolts by providing the beefier bracket. When they cut back on bracket costs in 1997 they opened the door for these failures. Vibration is a known quantity with these engines and has been a factor all the way back to the first HD powered Buells. The vibration is not the real problem. The breakages are more a story of how the vibration (and other forces) are compensated for and mitigated . . . or in the case of the 1997 through 2002 tubers, not. Here is a link to a report on my own anecdotal experience http://home.comcast.net/~buellstuff/boltreport.html Sorry to hear you have joined the club . . . Don Casto Boulder, Colorado | ||

Jackbequick |

Buellistic - So in your opinion, what are the right installation procedures for the motor mount bolts and exhaust system. Jack | ||

Rocketman |

I personally doubt there's a cure if you go back to using the standard parts. If you replace the head (if like on my S1W it breaks too) and bracket and bolts, what's to stop it occurring again several thousand miles down the road. All you've done is replace the failed items for new ones. That's a fix, but for how long? So what is the fix? Weld the head when it breaks. That's what I did and I believe it to be a cure, at least for the head breaking. As for the bolts and the brackets, if they break they're cheap enough but surely a billet bracket has to be the answer and worth the extra if you want the insurance. Rocket | ||

Doncasto |

Hey Sean! Good to see ya! Don | ||

Buellistic |

Jackbequick: In "MY OPINION" and what works for me !!! Front Motor Mount: Put antisize compound on the TWO BOLTS threads, and anywhere there would be metal to metal contact so when torqued it will be correct ... Put together finger tight and let the mount take the weight of the engine ... Then torque the two bolts, then the rubber mount bolts(two bolts that hold the rubber mount to frame, then the rubber mount bolt) to spec's ... Exhaust System: Put antisize compound on all threads ... Put antisize compound on on the header where it slips into the muffler inlet ... Put every thing together finger tight ... Torque the four nuts that hold the header to the heads evenly(a little bit at a time)up torque spec's ... Then the front muffler mount bolt ... Then the two rear muffler mounts ... And last, the header/muffler inlet clamp ... In BUELLing LaFayette (Message edited by buellistic on October 02, 2005) (Message edited by buellistic on October 02, 2005) (Message edited by buellistic on October 02, 2005) | ||

Jackbequick |

Thanks for the info LaFayette. Jack | ||

Rocketman |

Hey Don, I'm usually here anyway, so hey, it's great to see you and always a pleasure just to see your name pop up. Maybe some of us 'old' timers should post more often. Rocket | ||

Doncasto |

Point taken, Sir Rocket. I am still hot on the trail for a possible return to Buellishness (ULY!) this winter. I am sure at that point I will have more to share (too much, again?). Cheers! Don | ||

Jusask |

OK, I was at the dealer today and focused in on the motor mount and bolts on the New Ulysses. Now, I'm thinkin that must be improved ..... taking into consideration all the bolt/mount failures Erik must've improved it for a fire/dirt road bike. My question then, Does anyone know if the bolts and motor mount on the Ulysses will work on the tubers or would it require a head swap? If so, will the Ulysses heads work on my S3T? I'm sure there is something very obvious that I'm overlooking ..... just a sec .... be right back .... gotta go look at my bike .........OK, it looks like it would fit. Anyone? | ||

Capndoug |

The installation of a new Nallin mount, on my 2000 S3T is almost complete. Just some final stock air cleaner mount fabrication and torquing a few bolts. The failure happened in the classic mode. Left bolt broke slightly below the surface of the head then the right side of the V broke. I think the right side broke first adding vibration which cracked the entry fitting to the exhaust so that was welded up since they don't make it anymore. Thanks for the tip on the Cobalt bits, Al, it peels out almost like drilling plastic. And thanks for the B018 specs Joanne. Floppy will be out to play for Christmas. | ||

Sleez |

well we have another!! the left bolt on wedgie is broken flush with the head. the right bolt seems ok, and the bracket seems ok so far, i haven't taken anything apart yet, i wanted to research it thoroughly first! i was washing and waxing the S1W aka Thong aka Wedgie for a nice saturday ride when i noticed the "missing" bolt, upon further investigation...broken off!!! AAARRRGGGHHHH!!!!! ok....breath....relax....push her back in the garage....don't set her on fire....research on monday....have a beer....!!!! ok....it's now monday, the research begins!!! | ||

Capndoug |

Its good that you caught it before any collateral damage occurred, Sleez When I put mine back together with a Nallin mount, I believe the bolt was upgraded to special Grade 9 spec. I wasn't able to find cobalt left hand bits in town but right hand works well. I center-punched then pilot drilled and short hole then adjusted with a Dremel then into the bolt with the cobalt. It came out easier than expected. I never worry about the mount breaking with the new Nallin, but check the bolt at every days start to prevent a breakout of the head boss should one of the bolts give way. I'm not sure of the air cleaner mount is on the S1W, but with Nallin I had to fabricate and add-on to hold up the stock resonator. There were only a minimal amount of explicatives from tight clearances; have socket extensions and u-joints available or a wobble extension. I also removed the front fender. Double-check the torque specs against current/updated advisories. I also like to put tape over the frame bits that sockets and wrenches will rub during the process. Capndoug |