| Author | Message | ||

Oldog |

I have had some long standing issues with corrosion here on the coast, its un avoidable and my PM wheels while quite nice were being pitted and etched I had seen where "Lake Bueller" had coated his and was ok with the result. There are a number of alternative methods to deal with the issue Wet painting, "Zoop Seal", various polishes, and powdercoating. I wanted PC because the X1s' frame is PC it is some of the toughest stuff I have ever seen not to mention the nuke blue is beautieous.. The coated wheels will no longer require hours of polishing to keep them looking good.    rotors, pullies, tires, bearings etc must be removed. | ||

Oldog |

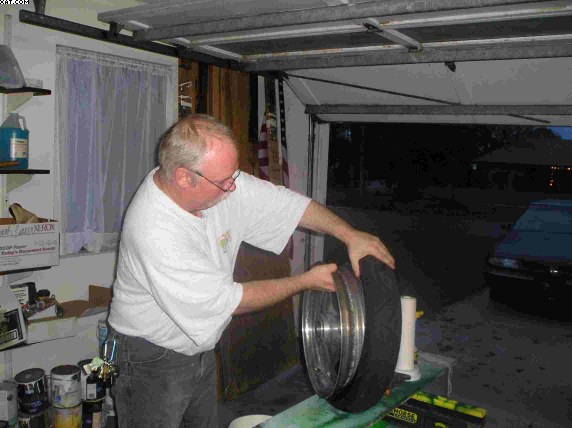

In the above the white patchy stuff will not polish out entirely, As "Lake" told me the valve stems may be removed with a box knife ( avoid scratching around the hole ) Balance weights pried off and the adheasive can be removed with lighter fluid.  the photo is not to clear but the weights' stickum provided some protection, the area under where the weight was is brighter. Opaque colored powder coat will hide the oxides all imperfections need to be smoothed. I wanted clear coating so I had to repolish the wheels,  this part of the job is time consuming and their is no way around it, I had damaged the rims finish in several spots where the rim protectors sliped from under the tire spoons and sevierly gouged the rim. It was bad enough to requre sanding from 180 out to 1000 grit, to remove the worst If you sand use wet or dry paper and sand with it wet, the paper cuts much better and lasts longer, because the water removes the debris. When the sanding was done I used a mothers powerball the power metal polish and a 20$ drill. This process is messy there are other and maybe better polish medias and tools I was not looking for show quality. The mothers custs fast and does a good job you will have to go over it a time or two to get it right. I took the wheels to Cape Fear Custom Powder coating, there Scott Simpson the owner went over the concerns of coating aluminum with me, Cast items because they are porous can OUT GAS these are bubbles that come up in the coating in the baking process, We tested the force winder elbow that I repolished it had numerous bubbles cast wheels are a little better as far as grade but they are cast and can have voids in them as well. Here are the wheels while re-installing the bearings. The Powder that was used was a clear polyester for good UV resistance. from some angles the wheels appear wet with oil, I am quite happy with the work, let me caution you IF you are in to shiney the wheels are nice but they are not as snimey as they were, from some angles the coating is visible as a grey orange peal I dont think that it is a workmanship issue as much as it is the effect of the light and the angle   (Message edited by oldog on January 07, 2007) | ||

Oldog |

| ||

Henrik |

Jim - that looks great! Good job. Henrik | ||

Reepicheep |

Those look fantastic! | ||

Oldog |

The coating has survived several encounters with HIGH heat I will be swinging by to get the tail and FW today, I am impressed with the durabillty of the finish. and recomend it for protecting and enhancing the appearence of a part Stay tuned.. | ||

Buellboiler |

OldDog, While the standard Buell wheels are cast aluminum, I don't think the PM wheels are constructed from cast aluminum. They appear either be forged aluminum or roll forged aluminum. Thus, the cast out gassing would be avoided. Please advise. Boiler | ||

Oldog |

The wheels are made in piecesm from plate and shapes, the basic spoke rim parts are spun to shape and welded together with a seamless tube as the hub the ends of the hub are machined to accept the plugs the welds are machined and polished, If you carefuly examine your wheels you will see this, Out gassing was neglible but some was present running the parts up to temp and allowing them to cool was the method used, they had to be recleaned and reheated ( mine did) | ||

Oldog |

Addendum I do not advise using clear coat over a polished wheel the powder coat cracked and I have "chicken puke" under the clear coat.  ~300.$ wasted roller stands, cheap battery drill, power ball, and elbow grease is better. | ||

Packrat |

Local powdercoater here refused to do mine in clear-coat, after he explained all the negatives, I understood why, and went with white..gorgeous, but need cleaning quite frequently... |