| Author | Message | ||

Quicksilver |

Fellas, I recently changed the intake seals, and forgot to loctite the intake bolts. I need to get in there again to put on a new airbox assembly. Should I tear the intake off, and loctite the bolts?? Also, I noticed a few auto parts stores carry permatex, instead of loctite. Is this product just as good?? One more thing, the manual says to apply HYLOMAR to the breather bolts. Will loctite do the same job here...???? Any help is appreciated. Thanks. | ||

Smokinjryan |

It does not say anything about loctite in the manual just says tighten to 6-10lbs | ||

Ragnagwar |

"Quicksilver" I have never found a need to loctite the intake bolts on my 2k/M2. The two products you mention perform the same job equally as well. "Hylomar" is a gasket dressing and flange sealant originally developed and used in the "Rolls Royce" engine assembly process. It is available from "Permatex" as Hylomar HPF at most auto parts stores. Seals oil leaks like a champ. No waiting time, just apply it, torque it and you're good to go! By the way, it does not harden, stays nice and pliable. Probably a lot more than you cared to know, but I hope it helps. "Rags" (Message edited by ragnagwar on July 19, 2006) | ||

Odinbueller |

I use Blue Loctite on a lot of fasteners. It's strong enough to keep fasteners in place, but it is easily breakable for maintenance. Also lubes threads & helps reduce cross threading on reassembly. I hate running in fasteners with dry threads. You do not want to use it on ground connections or on your inspection covers, however. Chris | ||

Quicksilver |

Thanks everyone for your input and advice. I've decide I'm not going to tear the bike apart just to loctite the intake bolts. I am going to replace the factory "bread box" with a dragtron II air cleaner, so I will use the permatex Hylomar for the breather bolts. Thanks again everyone!!! | ||

Jayvee |

Anybody change those allen bolts to hex-head? I saw a kit of four "allen replacement bolts" on either J&P or somebody. Saves having to bend or cut-down an allen wrench. Any particular reason an allen head is needed on the intake manifolds? | ||

Jackbequick |

Allen head bolts (cap screws?) are always sockets as far as I know. They lend themselves to countersunk locations or locations where there is not room to have a hex head bolt and still get a wrench on it. The latter is probably the reason the Allen head cap screws are used on the Buells. I cut a short piece off of a 3/16" Allen wrench, put it in the socket, and turned it with a 3/16" six point box end wrench for mine, seemed to work better than a Allen wrench. Jack | ||

Bluzm2 |

Jack, I'm trying that next time too! Good idea. I've gone through too many bent allen wrenched. It's tough to control the heat/temper when you bend them yourself. I should just order one from AL and be done with it. | ||

Road_thing |

Cut it with a hacksaw. If you use a grinder or a Dremel, the hex wrench loses its temper. By that, I mean the metal gets soft, not that it'll get mad and cuss you out! rt | ||

Jackbequick |

I don't think a hacksaw could have cut it. I used a Dremel tool with a thin abrasive disk to cut that off. As an ex gunsmith I have a good feeling for heat treating and tempering. The secret to cutting something like that off without losing the temper is to hold it in your bare hand or keep one finger near the cut. Every time you hear some say "Ouch!" stop cutting and cool it in a nearby container of room temp water. That way you will neither draw the temper or create any embrittlement. I could regale you with the numbers if you are interested, as far as where the average person says ouch and where the temper starts to go away. I also used side of the abrasive disk to soften the sharp edges a little. Those abrasive disks shatter easily, I never use them without my safety glasses on. I have probably gone through hundreds of them in my lifetime. I found a pretty good 3/16" six point wrench at Home Depot. It was branded Husky and is slim and nicely finished. Jack | ||

Road_thing |

Jack, every time I hold something in my bare hand and work on it with a Dremel I end up saying "ouch!" The great thing about those little cut-off discs is that at Dremel speeds they usually cauterize the wound as soon as it's open... rt | ||

Djkaplan |

I couldn't live without my Dremel tools. Give me enough of those cut-off discs and I could cut a truck in half... eventually. | ||

Jackbequick |

I don't think I've ever drawn blood with an abrasive disk. Now carbide burrs, that's a different story. But, seriously, I clamp one end of the Allen wrench in the vise and cut on the other but I do use my finger near the cut to monitor the temperature. Another great source of bits for cutting down are those 1/4" hex drive bits for use with power tools. I have a 1/4" hex x 3/16" hex that has been shortened on both ends and I can drive that with a 1/4" wrench or socket. I now have a little bad of odds and ends of bits in my tool box marked "Buell Specials". Jack | ||

Henrik |

Those shortened bits/wrenches work great with a ratcheting box wrench. Henrik | ||

Tnm2 |

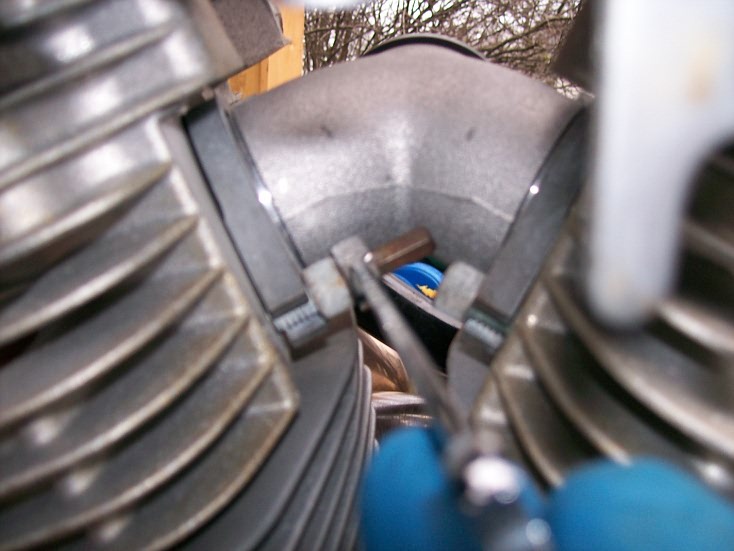

I know this is an old thread, but I thought this might be a good submission for the KV anyway. I've been using this method to swap intake seals with great success. These tools are available nearly anywhere. 3/8" drive, 1/4" hex ball driver.  1/4" GearWrench (ratcheting box end wrench) with a 1/4" hex bit in it.  Using GearWrench setup to remove inside bolts.  Using ball end to remove outside bolts.  I know this can be done with a cut off allen wrench, but fighting a bolt coated in loctite out a quarter turn at a time is a pain. | ||

Reepicheep |

Nice! Thanks! | ||

Tnm2 |

I'm still using the speed sensor saver you designed 5 years ago, Reep. I owe you a personal debt. | ||

Tim |

Totally off topic. Do you have more pics of the firebolt nose on your M2? How hard was it? Feel free to answer in the proper catagory. Thanks, Tim | ||

Tnm2 |

It is really pretty easy - essentially, it is mounted on 2 aluminum plates, one end bolted to the existing frame bosses, the other to the XB fairing bracket. I'll take some pictures of it and post them this weekend. |