| Author | Message | ||

Rick_A |

I use Loctite on every fastener the manual calls for. No problems yet. | ||

Henrik |

I usually do not use loctite on the primary cover bolts. Steel bolts into the aluminum case can seize, so per recommendation of a mechanic I trust, I usually anti-seize on those bolts. Otherwise I'll usually loctite and torque to spec. Henrik | ||

Rempss |

I don't use Loctite on most external fasteners, anti-sieze only. I use lock washers or Nyloc nuts to keep things in place. I do use Loctite on critical parts that are hard to check periodically. It's a personal thing with me. I have always done this on many cars and the few bikes I have worked on, never a loose fastener yet. It's great to work behind myself, everything comes back out so nicely. I don't necessarily recommend this to everyone, but it's always worked for me. Jeff | ||

Socal |

Cool - thanks for the input dudes! | ||

M2linc |

Has anyone out there installed the M6 primary chain tensioner by Hayden Enterprises? Any input as to how this automantic chain tensioner performs against the manual adjuster? Their website is; www.haydensm6.com | ||

Aaron |

Yes and yes. | ||

Littledog1 |

Lincoln, I second Aaron..ran and M6 for about a year, showed considerable wear on it's metal verticle support...NOT GOOD...replaced it with the latest HD stock unit. Mickey | ||

M2linc |

Thanks for the input guys, I will go for the updated tensioner. | ||

Mich |

Aaron, Littledog1, Could you please, tell me what were the symptoms which led you to control your M6 (noise or other...)? I personally installed a M6 chain tensioner in the primary of my 2K X1 when it has about 700 miles. Today, 15000 miles after, I never experienced any problem with it, no noise, no shifting problems... Only feed the primary with Redline Heavy Shockproof every 5OOO miles. Well, when I see your pics, I'm a little anxious ! So if I'm going to have a problem, I hope there will be some "warning signals" before the disaster...what do you think ? Thanks for your help. Michel. | ||

Littledog1 |

Michel, I put about 4K on my S-1 with the M6 but got nervous reading the various comments on BBS, so I pulled the cover to inspect. The primary chain was cutting into the M6 vertal guide. That ment metal was now floating around. It would not have been much longer before it cut through the piece and a LARGE chunk would have been circulating, I don't think mine would have made it 15K miles! Because of my consern over where the grindings from the M6 had gone, I changed the primary oil 500 miles after replacing the M6 and again a 1000 miles later. I too was running Redline Shockproof but have switched to the lighter Redline because of the 'Green Goo' that the Shockproof was leaving behind. Maybe the 'next generation' Sportser/Buell will have a gear primary? Mickey | ||

Mich |

Thank you Mickey, will keep an eye on this thing now ... Michel. | ||

Jasons1 |

Sorry if this is a redundant question...but does anyone know of a way to drain/replace my primary fluid without removing my Vanes & Hines muffler on my '96 S1? I just don't want to have to hassle with it, but want to begin running synthetic fluid. Also, is there any reason why I cannot begin using synthetic fluid? My bike has nearly 35,000 miles on it, and I have been running the tradional fluid since day 1, but I want to go with synthetics now. Any reason for concern, or should the change be nothing but an improvement? As always, thanks for the advice. Personally, I've found you guys on this site to be an incredibly valuable asset. Thanks again! - Jason | ||

Road_Thing |

Jason: No sweat, just pull the primary cover and tip your bike to the left!  r-t | ||

Roadrunr |

Jason, You could have started running synthetic 30,000 miles ago dude. Fill er up, no problem! | ||

Reepicheep |

JasonS1... a turkey baster or a syringe, and some plastic tubing will do the trick nicely. One of those baby snot suckers (forget what they really call them but they are a big rubber ball with a nozzle at one end) are at any drug store and would also work, maybe even without any extra tubing. Bill "with a lot of baby snot around lately  " " | ||

Djkaplan |

It's probably not important, but I always remove the drain plug so I can inspect and remove the metal shavings that collect on the magnet. The V&H isn't the easiest unit to R&R, so tranny oil change day is usually quite the event. | ||

Jasons1 |

Thanks all. Will I be able to see the top of the drain plug once I remove the primary cover? I've never had it off, and don't know. If so, once I have the fluid drained (I think I'm going with the Turkey Baster idea), I should be able to clean it off. Since I've never taken the primary off myself, are there any tips/suggestions when re-installing the gasket and cover? Thanks again! - Jason | ||

Road_Thing |

Jason, I was being a little facetious--I think the "turkey baster" suggestions are intended to be instead of removing the primary cover! You could probably suck the juice out by just removing the clutch cover and reaching in under the clutch with a tube on the end of a big syringe-thingy. That would probably be easier than removing either the exhaust or the primary cover, but I doubt you'd be able to see the top of the drain plug through the opening. Having said that, if you've got 35,000 miles on an original '96 model primary chain adjuster, you might want to at least have a look at it, and for THAT, you've gotta pull the primary cover. Tips for pulling the primary cover abound in the Knowledge Vault. It's simple, just be sure you have a new primary gasket and a new seal for the shifter shaft, as well as your new primary fluid, on hand before you start. As cheap as the new adjusters are, I'd go ahead and replace the old one pretty much regardless of what it looks like. I allow two beers max for the job. r-t  | ||

Reepicheep |

The two worst parts of the job are not really that big a deal. Getting the old gasket off the primary cover is a PITA. Gasket remover helps a lot, so have some of that on hand. Careful, it will also remove whatever they use to "paint" the primary cover. I brushed it on with an old toothbrush. The second biggest annoyance is keeping the gasket in place when you reinstall the cover. You need 5 hands. Either tack it down with some sort of gasket adhesive (rtv? gaskasinch? Yamabond?) or do what I did and cut a small dowel rod down into 3 or 4" sections, and sharpen one end in a pencil sharpener. Thread them into the case holes with the primary cover off, slide the gasket on them, then slide the primary cover over them sandwiching the gasket in exactly the right spot. Remove them one at a time as you put in the bolts. The turkey baster thing was as road thing speculated for removing the fluid through the derby cover without removing the primary cover or the primary drain bolt. Another option (that I have done) is to just wrap you exhaust in aluminum foil, make a channel towards the middle, put a big catch pan down, and just remove the primary cover slowly. A little messy, but it all cleans up easy enough. I agree with road thing about the primary tensioner as well. Replace it. | ||

Ara |

Jason, why are you trying to avoid pulling the drain bolt? Is it because of the mess on your exhaust can or is it because of a clearance problem between the primary case and the exhaust can? If the latter, you need to periodically clean the metal particles off the magnet on the drain bolt so that it will continue to do its job. I recommend you suck it up and pull the plug. If the former, the turkey baster/big syringe with hose will suffice to get most of the lub out of your primary prior to pulling the cover. I suspect that you're still going to have some drainage/mess if you don't pull the drain plug, just not nearly as much. Then you'll be able to pull the drain bolt and clean it. The aluminum foil trick is one way. Another is to cut down a 1/2 gallon plastic milk jug so that it will fit between the case and the exhaust. With that in place, you can pull the plug and the lube will drain into the "drain pan" you've made of the milk jug, and then out of the original opening of the jug into your real drain pan. It's reusable, too. | ||

Rick_A |

I just put a few bolts in the cover to hold the gasket. Works well enough. Seems to me the methods aimed at avoiding removing the plug are time consuming and a hassle in themselves. | ||

Jasons1 |

Thanks for the advice guys. I decided to just go ahead and pull the exhaust and get at the drain plug. It wasn't as bad as I thought. I just replaced all of the mounting hardware late last year, so it was all fresh and came apart easily. I just wanted to avoid having to do it if at all possible. I had just replaced my tensioner last year with the updated piece, and it still looked to be in good condition. The drainplug looked rather clean as well, so I think I'm in good shape. Filled the case back up with Synthetic fluid, and will be ready to ride as soon as the snow melts. Thanks again. | ||

Slag |

Hey i read the post about the auto chain tensioner and had a few thoughs( good or bad)? Are they set to go in one way , looking at the picturse the ware was on one side ? And is there one that works like the ones for the cam chains on other bikes? This might work for the back lash when it's in deselcoration ? Sorry for the spelling ,& too much free time on my hands!!! | ||

Reepicheep |

Slag... They are an interesting idea, but do a search for some of Aarons posts. The auto tensioners have the ignoble honor of being the only thing WORSE then the old stock (pre 02) tensioner. The primary chain grooves the sides of the tensioner (the M6 or something like that I think), which creates a burr that prevents the auto tensioner from tensioning. It does seem like something ought to be designed that could do it, but it is a much harder problem then a cam chain tensioner. Cams are a lot easier to turn then wheels. A cam chain deals with what... 1 horsepower max? The primary chain has to deal with 100 times that, maybe 200 or 300 if you dump the clutch on a botched downshift. It probably falls into the category of "something better could be done but it would be hard and expensive and the current solution is cheap and not bad enough to make it worth while"... | ||

Rick_A |

Some tinkerers with performance OHC repliracers switch their automatic cam chain tensioners for the manually adjusted type. It seems no matter how well they try to engineer the things they seem to never work perfectly. | ||

Jst |

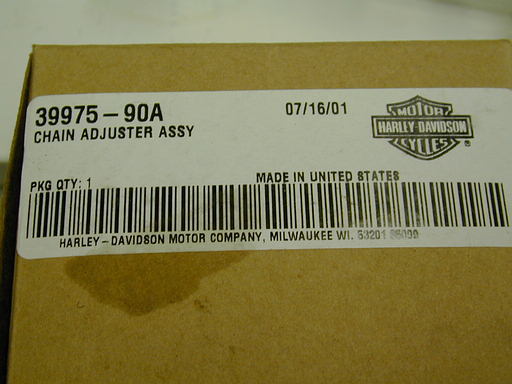

I just had the parts guy at the local dealership run the part number (33975-90A) for the suggested tensioner on HD net, He couldn't find it. He gave me 39970-91 as the correct part # for the tensioner. I'm betting that this is the old style one. Anyone got any idea as to how I can make sure and get the updated one? Regardless, they don't have one in stock and will need to order it. Does it make sense to order this from one of the fine sponsors of the board or not? Thanks JT | ||

Matty |

I don't have a book in front of me so I can't give you the correct part number, but 33975-90a is not a valid part number. | ||

Jst |

Thanks Chris, This is the number that Blake has at the top of this page. I'm wondering if it got fat fingered and the correct P/N is maybe something like 39975-90a. JT | ||

Court |

See if this helps....  | ||

Jst |

Court, As always you're a gentleman and a scholar. Does someone want to inform Blake the the wrong part number is listed at the top of this page? I'm off to see if I can crash the party at O'do Harley to get my stuff on order. Thanks JT |