| Author | Message | ||

Axtell |

Easyrider Au , Look @ the keeper groove in the valve stem and see if it has a sharp corner. Also look to see if there is a cusp left on either side of the break. Ron | ||

Barebonez |

Help, I found a set of cams that I didn't know I had. I can't remember what they are or where they came from. They are marked 2D on the inside of the lobe. I'm guessing they are a set of stock M-2 cams that I replaced for a friend of mine, but I'd like to be sure. Thanks, Kurt | ||

Peter |

They should be 1D, 2D, 3D and 4D. They are stock M2(USA)/Sportster cams. | ||

Benm2 |

I've got an idea, but its a stupid one. In the interest of reducing valve float at high rpm, could valvetrain mass & float tendencies be dealt with by replacing the lifter with a guide / valve spring assembly? The bottom of the pushrod could be "keepered" to the the spring, and the moving portion of the whole mess might (should) weigh less than the stock hydraulic setup. Any comments?? Ben | ||

Barebonez |

Peter, Thank you for your help. I feel a little humbled by my forgetfulness on the #’s (1,2,3,4), that I’ve successfully installed quite a few sets of cams in sportster engines seems of little consequence. I only pulled one cam out of the wrap & it said “2D”, I forgot they were numbered, duh! Thanks, Kurt | ||

Easyrider_Au |

Ron, I don't have the valve in front o me, so it's hard to answer your question sorry.....I've just tried sending Henry Duga an e-mail, but it's comin back tellin me access denied. I wanna know how I can contact the Buell hierarchy by e-mail......any suggestions?? | ||

Benm2 |

x1g: How much for the fairing?? BenM2 | ||

Axtell |

Easyrider au ; Can't help on a e-mail to buell---Court--Aaron,you have anything? Ron | ||

X1glider |

Ben, I keep forgetting to look at the price. I'll make myself a note to check tonight. | ||

Forevernow |

hey ,does anyone know if it makes sense to in stall cam needle bearing instead of bushings?i had my 99 cyclone at the local dealer for some engine warranty work ,so while it was apart i had them install some .536 cams with springs and nallin hurricane pistons .when i went to pick it up i found out that they had switched the bushing to needle bearing,i am no expert but i have heard that these work no better than bushings and can cause timing problems, any opinions? | ||

X1glider |

Started a preliminary inspection of my engine, which had a non-combusting front cylinder. To start in the simplest way, I removed the pushrod tubes and noticed the pushrods or lifters weren't moving up and down. So, off comes the cam cover. Holy Shit!!! My front camshaft had 5 teeth sheared off. Further teardown revealed a destroyed oil pump, scarred tappet rollers and scarred crank pinion. I found one cam tooth. The other 4 must be ground up or are plugging something up. The oil which, was 10 minutes old at the time of failure, shows lots of metal contamination. Without further teardown I won't know if the top end has suffered as well. What I do know, is anytime you have to split the cases, replace the crank assy, bearings, cams, lifters, pump, your looking at serious dinero! This is much more than I thought was wrong. I'll be tearing down the rest as I see fit when time permits. I've spoken with Headquarters, who supplied the cams, and they don't believe that there are teeth sheared off. Why is that hard to believe? I have a feeling restitution will not happen with them. They might replace the cams if I'm lucky. Andrews does the work for them. I am currently waiting to hear back from them. Negotiations... | ||

Pmcburney |

Question about noisy tappets... My M2 develops an extremely noisy tappet (seems to be one of the rear ones) after an extended ride ie. when it gets hot. After the motor has cooled, the noise is not present. I'm not sure if it's an oilway related problem or a lifter/tappet problem. I bought the bike as a wreck and restored it... upon initial startup from sitting for all that while, there was some tappet noise that could have been put down to a lack of oil in the right place. The bike has been back together for quite a while now and gets used on weekends and the odd commute. Any ideas?? Thanks Lee | ||

Rempss |

Does anyone know the difference between 1990 pushrods and later versions? My dealer has some Rivera adjustable units at a great price, but the catalog number is for 1986-1990 Sportster, there is a different number for 1991 and later. He tells me they are the same. Is this true? They do measure about the same length and O.D. Thanks, Jeff | ||

Ocbueller |

Lee, Some of these motors have very noisy valvetrains, some not so noisy. Just be sure to keep fresh oil in the motor, the properties of the oil diminish fast. I may be anal but I change mine every 1000mi. Especially if I have been running hot in traffic. If the oil is on it's way out, the hydraulic lifters don't pump up like they should, hence the clatter. I think if you had a serious problem you'd probably know soon enough. Enjoy your Buell but pay attention to it, you'll love it. SteveH | ||

Rick_A |

Can anyone tell me up to what years the current XL 1200 9.0:1 compression (I believe they are about 75cc chambers) heads were made to? I'm planning a future project and would like to know how old I can go with used heads for a current XL engine. | ||

Jmartz |

I recently refreshed the top end of my bike. The exhaust valves were quite pitted on the seat contact surface so I replaced them with new stock ones from the dealer. To my surprise they were a bit different. The area that faces the port was steeper in rise toward the stem and the transition to stem was rather "stepped". They also seemed to be heavier. It is possible that Buell has changed vendors or that this new design redirects flow better. I don't know though, more weight and a smaller opening at any lift do not seem like an improvement. | ||

Rick_A |

You shoulda just bought some aftermarket one piece stainless valves. Did you know most factory valves have the stem and head welded together? | ||

Jmartz |

No I did not, what a bunch of crap..! Guess I'll be opening the top end again soon anyway. The way the engine is designed and the way I treat it, peak performance diminishes after 15,000 anyway. Are you sure stainless is good for a valve? Xacto stainless steel baldes don't hold the edge worth shit. | ||

Rick_A |

Next to titanium I'd say stainless it best. Any steel ground to that fine of an edge is going to be fragile. Under normal parameters stock valves are fine...but i'd rather have that complete piece of mind. Funds willing, my motor will have serious mods/upgrades next year. | ||

Jmartz |

This is my experience with the Buell motor: The bottom end is indestructible. The top end (the hot setion) needs periodic refreshments. The clutch/trans components are very good but the shifting dogs are weak, particularly in the 1st and 3rd pair. This last time after 18,000 (the rest of the bike has about 49,000) miles I removed the top end for its regular refreshing. I noticed the heads had suffered what I suspect is a little warping, as 3 of the 4 valves when hand lapped hit only 1/2 of the seat surface. The AAC cylinders were still cylindrical and the same diameter but they has fairly deep (ca. .010) scratches near the bottom of the stroke. I think I am going to run velocity stacks from now on like I did on my '69 Triumph in the 70's. I don't think filtering the air is necessary for a life that's just around 15,000 miles before tear down. Power starts to diminish when the seat/valve contact surfaces erode from carbon particle abrasion, then oil that gets by the intake stem seal cakes up on the back side of the intake valve obstructing fill flow. The intake manifold o-rings harden and the mixture becomes lean. The rings weaken and the compression diminishes and finally the straw that breaks the camel's back is that either the cylinder head or base gaskets begin to weep. | ||

Rick_A |

I hope that won't be my experience  I given the velocity stack idea some thought myself...but with a fine mesh to stop anything big. I'll let you be the Guinea pig! I see a lot of 'em in UK streetfighter mags, too. | ||

Hoser |

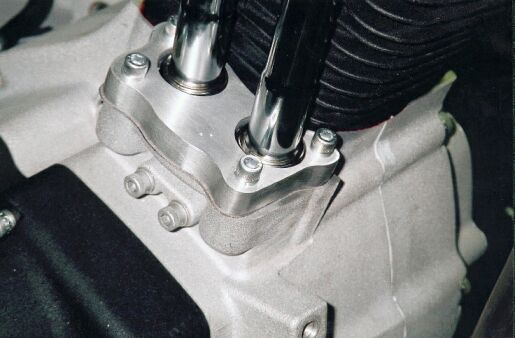

I figured this to be of interest....................   When cylinder heads are "decked" or cylinders are "trimmed" to adjust deck height the plastic pushrod tube may no longer fit properly. This is the solution , on an XB9 the rear adaptor would be a mirror image of the front. J.D.H. | ||

Lake_Bueller |

Rocker box question #1,234,642..... What's the best method for removing a VERY caked on gasket? I'm working on my project S3 and replacing the rocker gaskets. The front was a piece o' cake. The rear had been less than friendly. After getting the cover off, the second section had to be pried loss. Then I moved the lower section to find a gasket that is quite literally BAKED ON!!!! I tried to carefully get under the gasket with a straight razor but that only work in small amounts. I tried using a 3M Scotch Brite pad, no luck. Now I'm looking for suggestions. Any suggestions would be greatly appreciated. Living in rocker box hell, Mennis | ||

Peter |

Paint stripper. Don't get it on any paint though  PPiA | ||

Lake_Bueller |

Thanks Peter!!! I'll give it a try. | ||

Hootowl |

Have you tried gasket remover or goof off? The goof off won't hurt the paint (it's powder coated) then use a hard plastic scraper so you don't damage the aluminum sealing surface. | ||

Rattler |

Repeated gooings of Gasket remover will get it off..as others say..be careful with the aluminum... I use the spray version sprayed into the cap, coat it on with a small paint brush...keeps it off other metal...replace with the newer one piece metal HD rocker gaskets..you'll never have to live thru this again! Dale A. | ||

Reepicheep |

I carefully used a good narrow wood chisel (honed on 1200 grit sandpaper) with the gasket remover spray (spray into can lid, use brush to put on gasket). Definetely the worst part of the whole job. | ||

Lornce |

Curious about cams and flywheels.... I've read that beginning with the '96 S1's some sort of 'Screamin Eagle' cams were used... and became known as the 'Lightning Cams'. I've also read that the '96 S1 used essentially an 883 head fitted with larger valves and bigger ports. The same source suggested S1's also had lighter, thinner flywheels for revability. Question #1: What sort of cams, flywheels and heads were fitted to '95 & '96 S2's? Question #2: What sort of cams, heads and flywheels were fitted to '97 S3's? Question #3: What sort of cams and flywheels were fitted to '98 S3's? Question #4: Do "Thunderstorm" motors, whether fitted to '98 S1W's, '98 S3&S3T's or later X1's and S3's all use the same cams? And #4b: are they the same as earlier 'Screaming Eagle' or 'Lightning cams'? Would appreciate any information ya'll may have floatin around in yer gourds.... Thanks, Lornce | ||

Aaron |

"I've read that beginning with the '96 S1's some sort of 'Screamin Eagle' cams were used... and became known as the 'Lightning Cams'." Yes, that's true, although they were around before there was a Buell Lightning, they are commonly referred to as Lightning cams because they first came already in a motorcycle in the Buell Lightning engine. "I've also read that the '96 S1 used essentially an 883 head fitted with larger valves and bigger ports." Nope. The 883 head is a bastard. Small ports and a low roof over an open chamber with no squish bands, they take a longer valve too. The Lightning head is actually an XLH1200 head with a different, smaller chamber (same ports). It has a pair of 10 degree squish shelves and nets 10:1 with flat tops. "The same source suggested S1's also had lighter, thinner flywheels for revability." Yep. "Question #1: What sort of cams, flywheels and heads were fitted to '95 & '96 S2's?" Stock XLH1200. "Question #2: What sort of cams, heads and flywheels were fitted to '97 S3's?" Lightning. They came with Lightning motors just like the S1. The '97 -'98 M2 also came with Lightning motors with one exception: regular XLH1200 cams, also known as "D" cams. That's been the M2's distinguishing engine feature over the years, it's stock "D" cams. Oh, and it never got FI like the S3 & X1. Funny thing, though, international M2's got Lightning cams. "Question #3: What sort of cams and flywheels were fitted to '98 S3's?" Same as the Lightning motor. The '98 S3 (and S1W) use a Thunderstorm motor, but the difference is the heads. Cams and flywheels are the same as the Lightning. Flywheels changed in 2000 for all the bikes, though, to a lighter design with a pressed crankpin. "Question #4: Do "Thunderstorm" motors, whether fitted to '98 S1W's, '98 S3&S3T's or later X1's and S3's all use the same cams?" Kinda. Starting in '00, they changed the cut on the teeth between the pinion gear and the number 2 drive gear. So the part number of a set of cams changed. Then in '01 they propogated that new tooth cut (high contact ratio) to all the gears interconnecting the cams. You can buy the old style cams as part number 25648-91 or the new style as part number 25648-01. "And #4b: are they the same as earlier 'Screaming Eagle' or 'Lightning cams'?" Except for the gear cut on the '00/'01/'02, yes. They have the same timing and lift. |