So, you bought a cool aftermarket muffler with the thunderous sound to die for, and a high-flow air intake system that doesn’t look like a wart on the side of your carbureted Buell. Everything you’ve read says that the combo is good for 10 or more extra ponies once the bike is dialed in. But there’s the rub. You don’t have access to a dyno, and even if you did, you aren’t convinced you want to pay Dyno Dans $75 per hour to dyno tune your bike with each change of components, weather, and altitude. So you resort to anecdotal jetting based on web comments from someone that has a similar muffler or intake, and figure you’ll just compensate a jet size or two for the fact that they live at four times your altitude. Or maybe you figure that you can read the plugs and get it close enough. You’re sure it’s pulling harder than it did before, after $500 of parts and 4 hours of carb/jet swapping, it must! If only there was a better way of ensuring the jetting really is optimized….

This article describes one alternative to using that expensive dyno tuning service for dialing in the jetting for peak ponies. Air/Fuel (A/F) ratio meters that use O2 sensors in the exhaust are common, and there are lots of anecdotal stories on the web of folks that have used them “successfully” on their Saturn motor or Honda Fuel Injected (FI) autocross car. But there isn’t much out there that confirms that a cost effective meter can be used to accurately predict peak WOT horsepower when tuning a carbureted motorcycle engine. In fact, even FI vehicles don’t use the O2 sensor for getting peak power at WOT, they depend only upon the engine mapping done at the factory. Since there wasn’t enough empirical evidence behind the readily available info on using such a system, I set out to determine if an A/F ratio meter could be used to accurately tune our hot rod sporty engines for peak power.

Theoretically speaking…

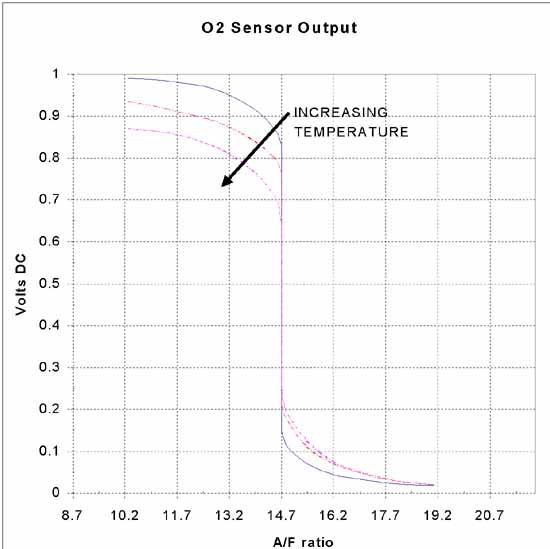

An oxygen sensor works by outputting 0 to 1 Volt DC based on the amount of residual oxygen sensed in the exhaust gas. A richer mixture consumes more of the oxygen and causes a higher voltage output, which is read on a specialized voltmeter. The stoichiometric mixture, where the A/F ratio is optimized, is approximately 14.7:1 (i.e., a mass of air of 14.7 to a mass of fuel of 1) for gasoline. This ratio is where the engine will get the best fuel economy and have lowest emissions. But it’s not the ratio that will provide maximum power, which is obtained somewhere around 12.8:1 give or take a few points (depending upon fuel composition). The O2 sensors are highly non-linear, as shown in Figure 1. They are optimized for controlling FI motors where the computer controlled injectors keep the ratio at 14.7:1 by varying injector duration to maximize the number of 0.45-volt crossings, which happens many times per second. The exact voltage output by the O2 sensor is not meaningful for determining an exact rich A/F ratio, since different sensors, and even the same sensor at different temperatures, have different output voltages at the knee of the curve. However, while the sensor/meter can’t tell us exactly what voltage equals 12.8:1, the max power should occur just after the knee of the response curve. The theory is that that the knee of the curve should be able to be determined by observing the meter ballistics as the meter transitions from a very bouncy reading to a somewhat steady reading, and that tuning to approximately 12.8:1 should be possible if approached from the lean side. There was some uncertainty as to whether the O2 sensor would accurately sense just the burned mixture given the amount of valve overlap that exists in an S1 with Lightning cams. So off we went to the dyno to confirm the theory and determine if the sensors accurately indicated mixture and therefore predict peak power.

Figure 1. Oxygen Sensor response

Testing..Testing

The first step for testing an A/F meter is to modify the header to mount an unheated O2 sensor a few inches from the rear exhaust port. Look at any of the 99 or later FI Buells for how they are installed. I fabricated a similar fitting from stainless rod and had it welded to my stock S1W header as shown in Figure 2.

Figure 2- Oxygen Sensor fitting, Inset is Air/Fuel Ratio Meter

The first question to be answered is if the modification of the pipe hurts peak power and makes the measurement meaningless. So we did baseline pulls on a ’96 T-stormed S1 with a Mikuni HSR42, a ‘98 S1W header, and a V&H muffler. Maximum power was obtained with a 157.5 jet (note: it was a 45-50°F, rainy day at 5400 Feet altitude), with a 160 jet giving virtually the same readings. We then swapped the header with the modified S1W header and did comparison runs with the same 157.5 jet with the fitting capped and with an O2 Sensor installed. The results of those runs are shown in Figure 3. It is clear that power was not degraded, and was in fact higher, likely due to small differences between the two headers. Convinced that the rest of the testing could be meaningful, we now set out to correlate power with meter readings.

Figure 3. Stock Header, Modified Header with Plug, Modified Header with sensor

An Autometer A/F meter with 20 LEDs (5 red, 10 yellow, and 7 green), each indicating 0.05 VDC was connected to the O2 sensor. A series of dyno pulls were performed with first richer and then leaner main jets installed. Figure 4 shows the results of those dyno runs and meter readings. With each run, the meter reads full rich as the motor is started and the sensor comes up to operating temperature. The first run was with the same 157.5 jet that indicated peak power in the previous baseline runs. As the sensor came up to temperature, the meter was bouncing in the top 3 of the yellow and the first green LEDs through the lower RPM range of the runs and steadily lit the second green LED and flickered the third LED through the upper engine revs of interest. Going richer to 160 flickered the first green LED green through the lower RPMs and solidly lit the third green LED as RPMs increased to redline. The 162.5 jet gave a similar result, but lit the fourth green LED solidly as the RPMs increased. Going leaner to a 155 jet caused the meter to bounce in the top 4 yellow LEDs and just barely lit the second green LED near redline. A 152.5 jet caused the meter to bounce over the full stoichiometric yellow LED range, rarely lighting either the green or red. Lastly, a 150 jet was put in and the red lean LEDs stayed on through the first 1/2 of the RPM range and slowly bounced into the stoichiometric range as peak RPM was obtained. The meter readings were very bouncy as expected through the stoichiometric range, but were quite steady as the display moved through the knees on both the lean and rich end of the readings. These results confirmed the theoretical output response and showed that if tuned so that the meter displayed that it was transitioning through the knee of the curve, from a bouncing flickering reading to steadily lit rich readings, optimum jetting could be APPROXIMATELY obtained. It was not obvious from the readings whether the 157.5 jet or the 160 jet was optimum. However, it should be noted that the dyno is not precise for determining this either. For example, some runs with the 160 jet had higher power than some runs with the 157.5 jet. It takes some “eye-averaging” of several plots from those pulls to select the jetting that gave the best performance, and the difference was less than one horsepower either way.

Figure 4. Different Jet Dyno Curves and Their Corresponding Meter Readings

One more test was needed to determine if this would be an acceptable tuning method. If the meter indicated substantially different readings as ignition timing was varied, then one wouldn’t know to change the timing or the jets for any given reading to get the right meter reading and optimum performance. This test wasn’t run on the dyno. A baseline blast down a straight road at WOT was performed with the timing at the nominal setting. It was then moved two ticks (10 degrees) advanced and retarded, and similar WOT runs performed. No significant change in meter reading resulted in either case, though there may have been a very slight bias towards richer indications as the timing was advanced

Does it work?

The conclusion is that for this mildly tuned street motor with mild cam overlap, the O2 sensor and A/F meter combo is reasonably accurate for selecting the jetting for peak power. But this setup allows for more than tuning for peak power. I didn’t have an eddy brake dyno that would have allowed steady state runs across partial throttle and variable loads, nor did I have a metered fuel and air delivery system for correlating the actual A/F ratio against the indicated readings. But it is a relatively small leap of faith to assume that if the system is accurately predicting peak power, it can also be used to optimize the pilot and needle jetting at partial throttle to keep the bike in the stoichiometric range. A properly calibrated across-the-midrange carburetor will maximize fuel economy without penalty, since any demand for more power is always just a twist of the wrist away. Subsequent road testing of my S1W with the meter installed has resulted in rejetting of the pilot and needle settings in my carb to leaner settings. My mileage has increased from 45 mpg to 51 mpg in normal usage, with no negative effects on driveablity or performance

For many of us, neither our bikes nor the environment we run them in is static. With an A/F meter connected, a new air cleaner, a change of the exhaust baffles or packing, or the change from summer to winter doesn’t mean a trip to the dyno for another jetting change. And an Air/Fuel meter is a lot more portable than a dyno.

Acknowledgements

I’d like to acknowledge Aaron and Susan Wilson for providing the facilities, motorcycle, and dyno expertise to perform this testing, and Jerome Chappellaz for his inspiration for performing this test. Jerome’s road testing of an A/F meter and his results posted on Badweb led to the questions that this article hopefully answers.

Battle Gear

K&N Unheated O2 Sensor- (includes plug and unsuitable weld-on fitting) - 85-2438, $59.95

(see http://www.knpowersports.com/docs/air_fuel_monitors.html for K&B Tech tips)

Buell Unheated O2 Sensor- 65970-99Y, $24.10

Beck Arnley Unheated O2 Sensor - 156-8100

Bosch Unheated O2 Sensor - 12014

AutoMeter Phantom A/F meter- 5775, $53.95 (see http://www.autometer.com/hp/index.html for AutoMeter tech tips)

Autometer Black Meter mounting cup- 2204, $12.95

Weld Fitting-Buell style fitting not commercially available, fabricate from stainless bar stock.