| Author |

Message |

Aaron

| | Posted on Saturday, August 03, 2002 - 08:37 am: |

|

Well, I read what Gary wrote and I don't interpret it that way at all. Read it carefully, he doesn't say the dip is placed there intentionally to meet sound requirements at that rpm. You could just as easily interpret his statement as saying the dip is a side effect of their quiet muffler design, which is what I've always assumed. Which is why I said it looks like they've done their homework on the XB's muffler.

This keeps happening, you keep posting that article (which I read thoroughly, years ago) and reading things that I don't think are there. You and I interpret it totally differently.

I dunno, I could be wrong here, but just thinking about it logically, it doesn't make sense that a torque dip would be put in intentionally to make it quieter at a specific rpm. A drive by at 3410rpm has to be a part throttle event, so it's torque & hp is substantially less than what the dyno chart is showing anyway. Seems like it doesn't matter what the motor's capability is at that rpm, you're artificially limiting it's torque (with your right hand) to whatever level is necessary to overcome the forces acting against the motorcycle (friction, wind resistance, etc) and maintain 3410rpm, and that level of torque isn't going to change whether the motor is capable of 20ft/lbs or 200ft/lbs or whatever. Create a torque dip there and you just have to hold the throttle open more to get the torque back and maintain that rpm. In fact, it seems like the torque dip could make things worse, because holding the throttle open more is going to cause more intake noise. |

Aaron

| | Posted on Saturday, August 03, 2002 - 02:24 pm: |

|

Anyhoo, this is infinitely more interesting, IMO ...

1995 Buell S2 Thunderbolt

Modifications:

100 cubic inch Cycle-Rama motor - 4" bore x 4" stroke

STD heads prepared by The Great and Powerful Wizard (aka Wes Brown)

Axtell cylinders

Ross custom pistons as specified by Cycle-Rama to match the heads

Whole big bunches of camshaft and compression (i.e., I ain't telling)

Mikuni HSR45 Pro-back (borrowed from Wes)

Dyna 2000 ignition (chosen for it's nitrous retard input)

Pair of Dyna DC6-5 coils (dual plugged, single fire)

Home made exhaust system, per Cycle-Rama provided specs

Keep in mind that as impressive as this result is, I'm being very conservative with this motor, in terms of it's timing and jetting, in both the gasoline and nitrous configurations. I could easily break 160 on gasoline and 190 on 30hp nitrous pills if I wanted to push it. I'm not going after every last hp with this one like I was with the 1000cc motor, I'm really much more concerned with keeping it together. Even though we put the best of everything into this motor, and took some special steps to make it stronger, we are *really* pushing things here. It's got to stay together long enough to do this, that's a much bigger worry (to me) than it's ability to make enough power.

The nitrous power of course is easily adjustable up or down by changing a few jets.The plan is to dial in just enough to get the job done, no more. Of course, that's kind of a judgement call, and you've only got a finite engine life with which to get it figured out. Wish us luck.

I made a video of a 155hp dyno pull, we'll get it on the web site next week.

AW |

Xgecko

| | Posted on Saturday, August 03, 2002 - 09:06 pm: |

|

Aaron, The fact that you got 155HP out of a pushrod gas motor scares the S$!T out me. I sure wouldn't want to ride that bike. And I am glad that the man who is riding it has been at those speeds before. Good luck to you and I hope it all stays together

On the subject of noise, I interpreted it to mean that they designed the muffler to provide its greatest sound dampening at the targeted RPM the fact that the design caused a resultant dip in the HP/torque was an unfortunante byproduct of being quiet. |

Aaron

| | Posted on Saturday, August 03, 2002 - 10:22 pm: |

|

Thanks, Tony, and we'll do our best.

I'm pretty confident in saying that the stock muffler's torque dip is caused by a reversion. In other words, the exhaust is sending a positive wave back at that rpm that arrives at the chamber at overlap time (i.e. both valves open). This shoves the next fuel charge back out the carb, before drawing it back in. Two reasons I believe this: 1) the stand-off you see out the carb as the motor goes through that torque dip, and 2) the M2 has much less of it and it's cams have substantially less overlap.

Now, when you look at a stock dyno sheet, you see the effect of that reversion, and then you see a good top end power number. In fact, the stock muffler spanks some much louder aftermarket mufflers in top end power. Clearly at the top end it's sending a negative wave that arrives at overlap time.

Well, if you've ever fiddled with making your own exhaust systems, this particular phenomena, of reversion a few thousand rpm below where the exhaust is really working, is a pretty common thing you run into. Basically, if you design it such that you concentrate the draw at a given rpm, you often end up with a positive wave not too far below it.

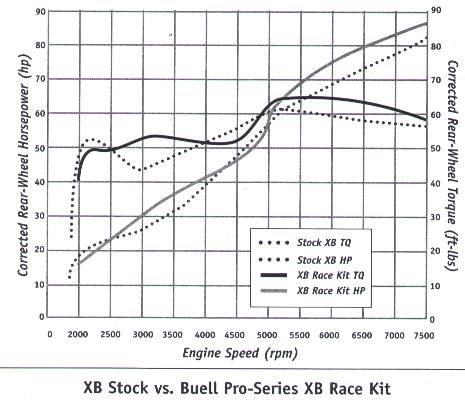

Anyhoo, it makes sense to me that in designing the stock muffler, top end power would be a priority. It's a marketing thing after all. And I'm not at all surprised that the reversion a few thousand rpm below it would be a side effect of optimizing it for top end power. I see that all the time. Hell, you can see it in the race bike's dyno sheet I just posted. See that crap at just over 4000rpm? And see the surge in top end power? Both of those things are the exhaust system at work.

I have a much more difficult time making a connection between a reversion and a reduction in noise. But I don't know that much about the whole noise attenuation side of it. I do know, though, that there are mufflers that are louder on the top end than the stock one and yet have less hp. So my perception is that they're not necessarily related.

Bottom line, I guess my rudimentary understanding of exhaust systems, be it right or wrong, is kind of underlying my interpretation of Gary's words. Perhaps that's why I see it differently.

But, since we don't have Mr. Valine here to tell us what he meant, I guess we're all free to interpret it the way that makes sense to us.

Here's something else to think about though ... if killing the torque at a specific rpm is necessary to reduce noise at that rpm, why don't they do it as much on the M2? |

Peter

| | Posted on Sunday, August 04, 2002 - 02:43 am: |

|

Aaron,

PPiA |

Buellistic

| | Posted on Sunday, August 04, 2002 - 01:46 pm: |

|

ATT: Aaron

Thanks for telling me why the inside of the air cleaner cover is always some what soiled.

ie: your post Sat 3 Aug 02 10:22PM...............

In buelling

BUELLISTIC and/or

Hardley-Harley |

José_Quiñones

| | Posted on Monday, August 05, 2002 - 07:12 am: |

|

Because the M2 had stock sportster cams which were matched sets until 2001, thus quieter.

The S1/X1/S3 use the lighnting cams, which are setup looser, so they make more noise. So they need to get the bike quieter through that dip.

The combination of INTAKE, EXHAUST and MECHANICAL (Engine) noise has to be lower than 80 db. So if you increase it in one of these sources, you have to do something with the other two to get it back down to 80 db.

Gary also wrote about this in the article.

Why don't you get Reg to call Gary at Buell and settle this once and for all? |

Aaron

| | Posted on Monday, August 05, 2002 - 09:52 am: |

|

Nah, it doesn't make sense to me (that the torque dip would be intentional), and he didn't write it, I ain't bothering him with it.

BTW, an '01 M2 and an '01 X1 use the exact same muffler ... same part number. Both have high contact ratio cams.

The Blast has a massive torque dip, despite having half the cylinders & valvetrain generating noise. |

José_Quiñones

| | Posted on Monday, August 05, 2002 - 12:14 pm: |

|

But they have different ignition systems, each one tuned to make as much power as the cams allow and still be EPA noise compliant..

Quote:and he didn't write it, I ain't bothering him with it.

Yes, this changed once they went to the high contact ratio design, but it's still something that they have to tune to, because it moves the torque peak one way or the other depending where they want it. The stock M2 still has the dip in that rpm range, it's just not as big as on the X1. |

Aaron

| | Posted on Monday, August 05, 2002 - 12:34 pm: |

|

José, you misunderstood ... man, leave two ways for something to be interpreted and you can bet someone will get it wrong.

Everyone knows "D" cams came fitted to the motors and Lightning cams didn't and they went to HCR across the board in '01, those things are not in question. I was saying that Gary didn't write that they intentionally kill midrange power to pass a drive by test. You still haven't produced a shred of evidence that that's what he meant, I've shown all kinds of reasons why that doesn't make sense. I think the killing of midrange power is a side effect of designing a quiet system that targets top end power. They gotta make just as much midrange to pass that test regardless, it's just that with the exhaust fighting them like that, it'll require more throttle opening. What good what it do to take it away with the exhaust when you just have to put it back with throttle opening? Makes no sense. Ride your bike and notice what effect throttle position has on the noise. It's HUGE!

BTW, my M2 came with the exact same ignition module that an S1 came with. |

Blake

| | Posted on Monday, August 05, 2002 - 01:21 pm: |

|

He's right JQ, it's the amount of power being produced that makes the exhaust noise, and the power required to keep a Buell twin under way at a steady 3410 rpm is not going to vary significantly between an X1 and an M2. If the sound test were at 3410 rpm and WOT on a dyno, your point might be valid. But each bike is running at the same power level, determined as Aaron says by the amount of throttle required to keep it moving at a constand speed.

I think that on the 1200 twins, Buell sought to get as much reliable performance from the engine as they could, then they designed, perhaps iteratively, the best performing EPA compliant muffler that didn't hurt the engine's peak performance.

With the XB9 muffler, I think Buell obviously aimed at a stock bike not with absolute optimum peak HP, but rather a stock bike with a fat torque curve and generous midrange. |

Aaron

| | Posted on Monday, August 05, 2002 - 03:12 pm: |

|

Damn, we agree on TWO things?

Will wonders never cease! |

Jmartz

| | Posted on Monday, August 05, 2002 - 04:30 pm: |

|

Aaron:

I noticed on you graph above that you spun the 4x4 to 7200. I thought redline on longer stroke engines was somewhat reduced. What gives? |

Aaron

| | Posted on Monday, August 05, 2002 - 04:33 pm: |

|

It was still making power!

If I was concerned about piston speeds & associated longevity, I'd keep it down a bit. But I'm not, this is a race motor. |

M2cyclone00

| | Posted on Monday, August 05, 2002 - 04:48 pm: |

|

Aaron & Wes, congratulations on that power. Of course, I expected no less! about 105 ft lbs of torque at 3000rpm. I need to save some funds to have Wes build me one, although, a bit more mildly tuned. His 130hp + version would be more than enough.

Dave |

José_Quiñones

| | Posted on Monday, August 05, 2002 - 09:43 pm: |

|

Quote:I was saying that Gary didn't write that they intentionally kill midrange power to pass a drive by test.

When he writes

Quote:One of the penalties we've paid, to date, for a free flowing exhaust that is sound legal is a midrange dip in the torque curve

The way I read that, he's saying that to get good top end power from the stock muffler and also keep it sound legal, they have to steal some from the "midrange" and give it to the "top end". This is because the noise test is not performed at WOT, it's performed in the midrange, where they reduced the power, and thus the noise.

Coincidence? I don't think so.

I don't see any other way to read that.

Whether they do it with the reversion or with a spark retard the effect is the same, the bike makes less power, thus less noise.

Later on he shows the effect of retarding the spark on an S2, and the reason that they did it:

Buell, and everybody else, tunes the bikes to pass the test, which has a very specific procedure, as he explained in the article (bottom part of the column):

The way you and I ride the bike on the street might or might not correspond with the way the test is performed. Buell tunes the bikes to pass the test with the way the throttle is opened in the test procedure, not how we might do it on the street.

Reversion is a fact of exhaust design, I'm not arguing that.

What I am saying, and what I read Gary to be saying in the article, is that they were and still are intentionally placing the reversion, and the resultant dip in power, in the area in the rpm range that helps them to pass the drive by sound test. If necessary, they will also retard the spark to achieve the same effect at whatever rpm they need.

Why do Australian Firebolts only make 75 hp at the crank? Do Kangaroos and Kiwis have sensitive ears?

If the drive by sound test wasn't the reason for the intake, muffler and power delivery designs, why don't the bikes come with the race intake, exhaust and ignition stock? |

Aaron

| | Posted on Monday, August 05, 2002 - 10:56 pm: |

|

"One of the penalties we've paid, to date, for a free flowing exhaust that is sound legal is a midrange dip in the torque curve"

The way I read the statement, they wanted a free flowing, quiet design, and unfortunatley, to do those things together carries a penalty (his word) in the form of a midrange dip. To read into it that the dip is intentional to put extra noise attentuation at that rpm seems like a huge leap to me, he doesn't say that at all. If it was intentional, why would he refer to it as a penalty?

Mess with making exhaust systems sometime, I think you'll find this is a pretty common phenomena. Optimize an exhaust for one rpm, you pay a penalty somewhere else. They haven't figured out how to get it good everywhere and quiet at the same time. Well, they have now, with the Firebolt muffler.

"Whether they do it with the reversion or with a spark retard the effect is the same, the bike makes less power, thus less noise."

Is the correlation that strong? Why does the stock muffler make more top end than many aftermarket mufflers despite being substantially quieter?

"they will also retard the spark to achieve the same effect at whatever rpm they need."

Your comments on the spark retard are making a similar leap. He doesn't say it's done to pass noise tests at the rpm where the retard is kicked in, that's an assumption you're making. As it was explained to me, the mid range test is done at 50% of the peak power rpm. So kicking in some advance early lowers the peak power rpm so the test can be done at a lower rpm. They're not using spark retard to lower the noise at the test rpm, although if lowering the power there were the goal that would seem like a whole lot better way to do it, reversion can be bad for a motor. I think you're assuming a much stronger correlation between power and noise level than actually exists.

"If the drive by sound test wasn't the reason for the intake, muffler and power delivery designs ..."

You actually interpreted my words as saying this?

I think you just made my point for me ... that's a huge misinterpretation of my words, even worse than the cams thing. You have a tendency to read things into people's words that aren't there. |

José_Quiñones

| | Posted on Tuesday, August 06, 2002 - 12:53 pm: |

|

Quote:Well, they have now, with the Firebolt muffler.

Ok, now we're back to where we started this little friendly debate.

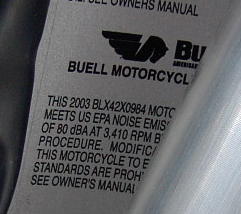

The stock XB9R still has a dip in the torque curve, and it happens to occur right at the range that the EPA tests it for sound output, in the midrange.

Like the sticker on the bike says, it makes 80.0 db, not 79.9, not 80.1, at 3,410 rpm, as the bike climbs out of the dip. Do you think this is a coincidence?

Quote:Why does the stock muffler make more top end than many aftermarket mufflers despite being substantially quieter?

Again, because it's only quiet in the rpm range that the sound test is concerned with, the midrange. The total sound output of the bike (which includes the muffler, the intake and the engine) does not need to be lower than 80 db at WOT, it only needs to be lower than 80 db in the midrange, where they test it.

Quote:He doesn't say it's done to pass noise tests at the rpm where the retard is kicked in, that's an assumption you're making.

When he writes "The power peaks at 5200 rpm and then drops because of a several degree spark retard. The spark retard was necessary to meet the noise limits" what is he saying?

It sounds exactly like what you are saying he is not saying, when he is clearly saying it.

Power equals NOISE. Noise doesn't necesarily mean power.

Every Buell to date has this dip, some more severe than others, and the reason for this dip and where it's at is the EPA drive by sound test, that's the whole point of that article, as I read it. It's not a lucky coincidence, they tune it that way on purpose, that's the only point that I have been trying to make.

We'll have to agree to disagree, but I'm sure if you asked Gary he'd tell you that they do in fact kill the power in the midrange on purpose to pass the EPA noise test.

PS - According to the part books, the ingnition module for the pre 99 M2s is part number 31652-96Y and the one for the S1's is 32418-96Y. |

Sarodude

| | Posted on Tuesday, August 06, 2002 - 01:25 pm: |

|

Here are some thoughts regarding this noise / HP discussion:

Exhaust tend to open at least slightly before BDC. Might there still combustion happening? If so, would EARLIER opening, all other things being equal, equal more noise?

Similarly, if one retards spark enough, would there not be later combustion, therefore a greater likelihood of the above scenario? If so, and if combustion during exhaust valve opening would cause noise (as the silly layman in me seems to think), would retarding ignition at some point result in a noise increase?

Unrelated, BUT with 2 strokes, some successful engine tuners I know used a very retarded ignition timing to HELP top end performance... Basically, there was still quite a bit of combustion happening when the exhaust port opened. This would increase the temperature of the gasses in the expansion chamber and cause in increase in sonic wave speed to allow the pipe to continue to work effectively a few hundred RPM past where it would otherwise have signed off.

Essentially, the late burn was used to alter the characteristics of the exhaust - which in turn altered power characteristics.

Anyway, none of us have done EPA noise testing / engineering so it's all conjecture and we should accept it as such. However, José does have the ignition timing quote as a seemingly reputable piece of interesting info...

-Saro |

Jmartz

| | Posted on Tuesday, August 06, 2002 - 02:03 pm: |

|

Aaron:

Are you runnig the 4 x 4 S2 on the salt?

José |

Jmartz

| | Posted on Tuesday, August 06, 2002 - 02:06 pm: |

|

Aaron:

Ran into another problem with the project motor. Zippers dual runner heads have big chambers intended likely for stroker applications. The 4 x 3 5/8 stroke displacement puts the compression below optimal levels. |

Aaron

| | Posted on Tuesday, August 06, 2002 - 02:59 pm: |

|

José: Hmm, looks to me like the dip is at 3000 and the test is at 3410. Why is it you think they're connected again?

Tell me this ... if what you're saying is true, why would they choose to do it with the muffler instead of the ignition? Wouldn't it be infinitely better to retard the timing than to create a reversion, with it's associated carburetion problems and risk of detonation?

On the reason for the high rpm retard, I was told point blank the purpose of the retard is to lower the rpm at which the test is performed. I didn't just make that up. I think it perfectly illustrates how you're not applying critical thinking to what you read, you're making assumptions far beyond what the words say.

"It's not a lucky coincidence ..."

Lucky coincidence? You haven't even established that reducing torque at that rpm is an effective way to reduce noise, that's a leap of faith that you've provided no evidence to back up. Maybe it's an unlucky coincidence! Maybe it's actually a penalty for a free flowing, quiet exhaust, who knows.

"... they tune it that way on purpose, that's the only point that I have been trying to make."

Oh, I understand what you're saying. I just don't see it in that article, nor do I think the fact that the dip is at 3000rpm and the test is done at 3410rpm is particularly strong evidence. So when you stated it as being fact, I challenged it. Maybe it is, I don't know, but you sure haven't made the case yet. And I can think of a whole bunch of reasons why it doesn't make sense.

PS: gotcha again ... not reading carefully ... go back and notice I said "my M2", not "all M2's". Mine is a '99. Uses the same module as an S1. |

Aaron

| | Posted on Tuesday, August 06, 2002 - 03:08 pm: |

|

Jose: yes, the purpose of the S2 is a salt flats racer.

Are you married to that set of heads? Zipper's makes good stuff, no question, but so does STD.

You can also get most any piston custom-made. Wes does that all the time. It really shouldn't be a big issue.

BTW, how's the 26T pulley working out? |

Jmartz

| | Posted on Tuesday, August 06, 2002 - 04:31 pm: |

|

Aron:

You must have missed my "report" but I can tell you that now it feels like I need the 6th gear. The bike feels stroger across the gears and the sweetspot speed is down from 78 to 75. If I had clip-ons and wanted more top end the 6th would be a must. I'm think of getting it anyway.

The part is exquisitly built and very, very light in comparison. Increase in wheelbase is practically nonexistent. |

Blake

| | Posted on Tuesday, August 06, 2002 - 06:01 pm: |

|

JQ,

With the higher 7450 rpm point of the XB9R's peak HP, the sound test would be run at a significantly higher rpm compared to the ~6,500 rpm peak HP of the 1200's right? The XB9R is probably run through the sound trap at somewhere around 4,000 rpm. There is no dip there. In fact the stock bike/muffler matches the race kit/muffler's performance.

That then raises the question, can you explain why the race kit/muffler has a dip below the stock bike/muffler from 4,000 to 4,700 rpm? Are they trying to meet some EPA restriction on noise at that rpm on an offroad race bike?  |

José_Quiñones

| | Posted on Wednesday, August 07, 2002 - 02:06 pm: |

|

Aaron & Blake,

Does horsepower equal noise? Mr. Valine seems to think so:

Quote:As the horsepower output of an engine increases, the exhaust and intake noise, and in many cases the mechanical noise, also increases

So if you want to lower the noise output at a certain rpm range, you have to lower the horsepower, so you HAVE to tune it so the power, and resultant noise output, measures no more than 80 db when it's tested through that range.

The sound test (F76A) does not concern itself with the upper rpm range. The test procedure might have changed since 1996, but I doubt that it has been relaxed since then, if anything it's probably gotten harder. I have not been able to find the test procedure on the net yet.

In the mean time, here's what Mr. Valine wrote about the test:

Quote:The sound trap, or length of track where the vehicle noise is being measured, must be a minimum of 32.8 feet (10 meters) long.

The motorcycle enters the trap at a predetermined engine rpm and gear, and the throttle is rapidly opened. The engine rpm must be turning at 55 percent of its maximum rated speed as it exits the measuring area, at which point the throttle is rapidly closed. For the most accurate testing, a programmable engine cutout device should be used to kill the engine at the trap exit.

Therefore, the sound test doesn't test the upper rpm range of the bike, so they are free to tune the top end power without having to worry about the sound, like I said before.

As quoted, the rpm range of the bike as it is being tested never goes past 55% of the maximum engine rpm.

In the case of the XB's, this would be 55% of 7500 rpm, or 4,125 rpm. So the bikes are only tested for sound from 0 to 4,125 rpm, where they happen to feature a dip in the power band.

For the tubers, if we use 6500 rpm as the maximum rpm, 55% of this is would be 3,575 rpm.

Stock S1's, S3's, X1's and the Blast have a considerable dip below this rpm, M2's definetly have a smaller dip, but it's still there.

Like I said before, we won't settle this until Mr. Valine is asked to "clarify" what he meant when he said that the dip in the power curve is the "penalty" of having a sound legal free flowing (ie Tuned for top end) muffler.

Is the penalty there by accident or by design?

____________________________________________________________

M2 Vs S1 ingition modules

Your's is a 99? Ok, I looked in the 99 Parts book and found that the ignition module for a 99 M2 is part number 31652-96Y, the same one for 97-98 M2's.

The part number for S1's and S3's from 96 to 98 ignition modules is 32418-96Y.

Your's came with a S1 ignition module? Is the parts book wrong? |

Aaron

| | Posted on Wednesday, August 07, 2002 - 04:13 pm: |

|

José, like I said, I ain't gonna rule out the possibility that you're right, but I don't agree that's what the article says, I think it's a creative interpretation and I can think of several reasons why it doesn't make sense. So if you state it here as fact, it may get challenged. You're certainly entitled to your interpretation. Enough already, who cares.

You better go look up the part number on that module again, though. Yes, the '96-'97 S1 used 32418-96Y, but the '97-'98 S3 and '98 S1 use 31652-96Y, just like the '99 M2. Page 27, item 13, both books. |

Court

| | Posted on Wednesday, August 07, 2002 - 05:08 pm: |

|

>>>>none of us have done EPA noise testing / engineering so it's all conjecture

Uh....not exactly true depending on your definition of "us". I think I know one of the best Motorcycle Acoustic Engineers in the business and, I assure you, it's an "art form".

If someone wants to reduce this discussion to an "answerable" question, I'll dangle it.

Court (Not an Acoustic Engineer, but played one in a 6th grade play once) |

José_Quiñones

| | Posted on Wednesday, August 07, 2002 - 09:28 pm: |

|

Well Court, is my question answerable?

Is the "penalty" in the midrange there by accident or by design?

Aaron,

Yep, you're right about the Ignition modules. |

Aaron

| | Posted on Wednesday, August 07, 2002 - 10:01 pm: |

|

We know it's there by design and not an accident.

The question is whether the mid range dip is there as a trade off to get more top-end power, or it's there because cutting the torque at that rpm is necessary to pass the drive by test. We read the evidence very differently.

The whole thing is kind of a nit anyway, and I certainly don't think settling online debates is an appropriate thing to be bothering people at Buell over. Let it go. |

|

»

Buell Dynamometer/Dyno Testing Archives »

Archive through August 07, 2002

»

Buell Dynamometer/Dyno Testing Archives »

Archive through August 07, 2002

»

Buell Dynamometer/Dyno Testing Archives »

Archive through August 07, 2002

»

Buell Dynamometer/Dyno Testing Archives »

Archive through August 07, 2002