| Author | Message | ||

Buellzebub |

ara, it's my understanding that the 98 and up pumps have a larger scavenge section than the earlier models, so it ain't really the same as the old one [part numbers above seem to confirm this]. | ||

Steveshakeshaft |

I haven't taken any notice of the XL oil pump (it works!). But I am noting the concerns about losing prime on the scavenge side of the pump, IE the "drawing thru a straw in the air scenario". I note from Aaron's description he is concerned about oil bleeding from the feed into the scavange side of the pump? It is quite normal in many circumstances to bleed oil from one side of the pump in order to maintain the "prime" on the pump inlet. This is seen very often in all kinds of oil systems. Naturally, the pump discharge will be sized to take account of this built in "loss". HTH. | ||

Ralph |

Bubby, I measured the gearotors on the '96 and '98 pump and they were the same size. I don't know why they have a different number. I could no see any difference. That's one reason why I'm so curious about the '01 pump. bighairyralph | ||

Rapid49 |

I am finally getting ready to put my S1 back together! Any thoughts on aftermarket cylinder studs? I've also noticed no mention of gapless rings. total seal gapless is all I would use when I was building chevys. I plan to use them in my Buell. The new ones have the gapless ring in the top position.I've not used them in this configuration. Any thoughts apreciated. Evan | ||

Blake |

I dunno about studs, but can I get a SS cap please? Or at least one with adequate plating to resist corrosion? Any suggestions? | ||

Peter |

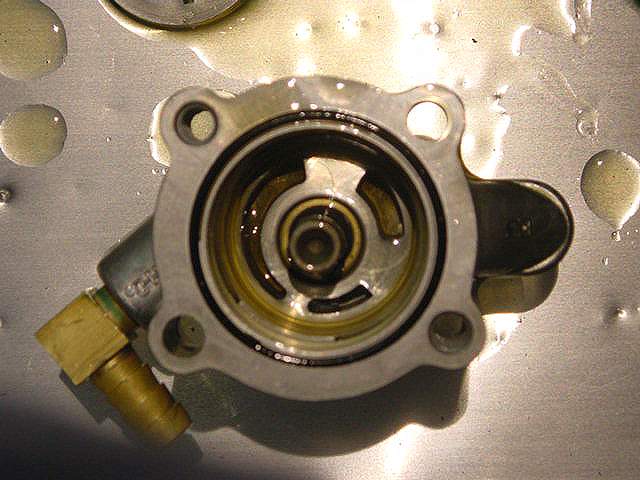

I had a look in my '00 M2 manual and it's states changes to the cases and cam cover, but no mention of the oil pump, so I think you're right Ralph. It still has the '98 pump. Then I looked in a '01 manual for an X1. Changes to the cases and cover (unsure if these are *new* changes from the '00, or the same as the '00 had from the '99) and a new pump. Here's my '98 pump.   If I were to seal the offending hole under the drive gear, and drill the cam case drain in the old position, I'd assume that whilst I'd get rid of the two straw problem, I'd encounter another of not having enough oil being scavenged back to the tank, as I've reduced the pumps inlet capacity. Does anyone have a '01 pump that they can pull apart and take pictures of like these two? I'd like to see if the '98 pump is modifiable before I spend big bucks on an after market one. PPiA | ||

Buellzebub |

Ralph, thanks for the info, i had read about this change in an old Battle2win[issue 2-1,pages 56-58]. scavenge section was .2" longer, with a housing length of 1.64" versus the 1.46" of the old one[not sure why the math doesn't work though]. i'm curious about this too, as i now have a 98 S1 as well. | ||

Ralph |

I'll remeasure the different pumps over the weekend. I may be mis-quoting myself. bighairyralph | ||

Axtell |

Had the dreaded "no text box" for the last few days....Ara, I don't know if you got the right explaination on your engine demise. Usually slow or "lack of scavenging" just causes a mess. NOT pumping oil into the engine would certainly kill it. What I mean about the late pump being a problem is that the majority of the pumps I have data on show that they will probably not pump the volume and pressure required to keep a engine happy when hot. Ralph has oil pump pressure data-ask him.. Peters photos tell a story about the two straw theory---if you look at the scavenge ports in the body you can see that dividing wall that lets the pump sip on one straw then it switches to the "other" straw. Mike J...I'm on your side on flywheel weight...never warmed up to the light ones....too hard on parts and their thin cross-section limits the oil sling to the pistons. Twin cam pump is bigger AND spins engine rpm instead of the XL's 1/2 engine rpm | ||

Ralph |

I don't have a big enough cross section to be able to conclusivly say anything. Not that it ususally stops me  I would like to take this opportunity to say that from what I've heard, the multi-hundred dollar aftermarket pumps are not going to provide a marked improvement over the stock pumps except in the scavenging area. Once again, this was one instance. If any body else wants to drop $500 bucks for a pump I would appreciate knowing the before and after results. bighairyralph | ||

Ara |

Axtell, let me be more descriptive about my engine failure. It was a very hot and humid day, the bike (a '97 S3) was relatively new, and I was checking the oil level each time I stopped. I had observed the recommended factory break in procedure religiously, and the bike had received its 500 mile service. Each time I checked the oil level that day, immediately after turning off the engine, the oil was lower than the last time I checked. Alarmed, I added H-D oil up to the proper level. I had to do this several times. I thought that the engine wasn't fully broken in and was just burning oil, but I was wrong. The oil was progressively building up in the crankcase and adding oil was just providing more oil to accumulate there. Eventually there was so much oil in the crankcse that the falling of the pistons so pressurized the remaining space in the the crankcase that the oil was forced past the rings into the combustion chambers. There it burned and produced an absolutely astounding volume of thick blue smoke. I also had a thoroughly lubricated air filter and airbox. Now, here's where the the circumstances separated the dealership men from the boys. I was closest to Nashville, so Boswell's H-D picked up me and the bike. A week later they gave me the bike back, and told me that they'd fixed the problem. I thought there was something funny about it because there was no service work order or any paperwork at all to document that they'd "serviced" the bike. When I got it home, I discovered several interesting things. First, Boswell's had removed the nice brass emblem that Rider's H-D had put on the bike when I bought it from them. Second, the bike was progressively fouling the plugs. Third, the oil level in the reservoir was dropping with each short test ride. Boswell's hadn't done a damn thing. I called them and talked with their General Manager. He was quite acquainted with my bike, readily informed me that I had a bike with a "problem motor", and offered nothing in the way of an explanation for turning the bike back to me with known serious problems and without having done anything at all to remedy them. The bike was still under factory warranty at the time, so there was no excuse whatever. Riders H-D, the folks who sold me the bike, obtained a '98-spec engine from the factory under warranty for me, it was installed without any cost to me at all, and the bike has been a peach evry since. Absolutely flawless. That's the story, and I will never again darken the doorway at Boswell's as long as I draw air. Russ | ||

Jrh |

I just looked at the Mototuneusa website Big Hairy Ralph mentioned in a recent post.Theres an article saying basically,to get piston rings to "break in" or seat fully to cylinders,run the bike HARD but dont overheat for long periods. The theory is the freshly honed cylinder bores cross-hatchings must wear into the rings and create the ideal seal-ring to cylinder-before the cross-hatchings are too soon worn away.Once the cross hatchings are gone,if your rings arent seated they will never seat.As for the other moving engine parts this guy says the hard run break in wont damage them.They should not need to be "seated in"by an engine break in period if they had properly machined tolerances from the factory(my own clumbsy wording of what i think he said) Any opinions? Should we run the heck out of a new engine?Just the opposite of all ive heard before. Thanks | ||

Peter |

John, I read the same article. As it happened, I'd just fitted a set of rebored cylinders with new pistons and rings to my M2. I figured "what the heck" and ran them in, in the way he described. At worst I'll need to give it a hone and fit new rings if it's a bad thing. It's got over 500 miles on it now, with most of them being run hard with lots of wheelies etc  Time will tell, but for now it's running very well, not using any oil, not doing anything funny...... PPiA | ||

Moderator |

Sandman ignition questions moved to the ignition topic | ||

Peter |

Ron, I'm not sure if you have been reading this thread, but now I'm really interested in your thoughts on the problems with the '98 style pumps. Please? PPiA | ||

Axtell |

Peter, I would like to see a minimum of 20lbs of pressure taken @ the sender location with the engine and oil hot (oil temp at least 165) with the engine running 3000 rpm. The pictures Aaron sent of the S&S case show that they put first priority to the lower end and pistons then the valve train. This is the way all 4 speed sporty engines were set up and it makes more sense to me. Ron | ||

Peter |

Ron, I understand, but what has confused me is that it was fitted with a "two straw" pump ('98) but it had drains from the camcase back to the crankcase. I thought getting the oil out that way would really increase the pump's chances of sucking air? PPiA | ||

Axtell |

On a dry sump engine the scavenge side of the pump will always be pumping air and oil if things are sized properly so you shouldn't worry about air in that side of the pump. I am just concerned with the lack of feed side pressure. | ||

Peter |

Due to air, or due to rotor sizing or....? PPiA | ||

Ralph |

Due to design. Same as the size of the output shaft on the crank. bighairyralph | ||

Jmartz |

Aaron: Regarding the pictures of your S&S cases, the scraper,reed valve and bottom cavity are a great idea to control the engine's return oil. I remeber seeing on a vist to S&S their "Buell" flywheel set. These wheels did not have flat tops that could be scraped, instead they were "knife edged", as I believe they called them. What lower end do you plan to put in there? With the longer pinion shaft requirement using the modern monolithic units is not an option. Jose | ||

Mikej |

Jose, I've seen some "secret" stuff out in California where the cases were "tuned/modified" to work with the knife-edged flywheels. There (edited for the gramatical tense sensitive)  you missed one ya hick!   | ||

Jmartz |

Mikej: I have often wondered about those knife edge flywheels. As I understand it if you wanted a lighter unit, weight should not be removed solely from the periphery since it is in this area that the "flywheel effect" is ocurring principally. Rocket uses these units and is quite happy with them though. Jose | ||

Mikej |

There's more than just the weight factor involved when the builders start shaving the flywheels. Take a wine glass with a long tapered stem. Dip the base into some water so that you have beads on the bottom, then shake the waterbeads off. Next dip the top into the water, and while holding the base again try to shake the beads off the glass. That's how it was partly explained to me. Much easier for the oil to run down the face of a bevel than it is to fling itself off the sides and flat rim of the uncarved flywheel. This all sort of gets confusing when you consider the rpm's the flywheel is spinning at, but when the guy's sons were winning races with his engines I sort of figured he knew a little about the engines. When the builders and machinists start talking about rotational masses and dynamics and such then it's time to just sit back, sip your coffee, and listen. There, that again should be enough to get me into trouble again....  | ||

Jmartz |

Not to worry about that. I do not take this hobby too seriously, its just for fun. Seems like those knife edge wheels would be better suited for stock cases that do not have the oil control design built into them. | ||

Tims |

So why wouldn't a Buell benefit from very light flywheels? I mean we aren't talkin Harley Dresser here. My M2 weighs in at 215kg with fuel and oil which, up until the latest crop of lean Jap superbikes, was fairly respectable. Positively a featherweight compared to what comes out of Harley Davidson anyway. Has anyone had first hand experience with really light flywheels? No gains on the dyno maybe, but must be gains in the way such a bike accelerates on the road. Anyone tell me how much Buell have taken off their flywheels since 1998? Wouldn't the alternator rotor have more than minor flywheel effect, and be factored in? All adds up to a lot of unnecessary weight to me, especially if your tacho never sees under two grand anyway, unless idlin. Tim | ||

Mikej |

Tim, I'm really not the one who should be answering this. You have to define your goals, and what you mean by "benefit". Some people's goals for their engines benefit from shaved or lightened flywheels. Define your use, your goals, your desired power curve, then work on the engine to get those aspects accomplished. | ||

Blake |

TimS, Before Aaron responds (I know he would  )... )... Acceleration on the Dyno equates to acceleration on the road. Then again, I wish I could go from 40 to 110 mph in 5.5 seconds like on the dyno. The dyno actually sees more of an effect from lightened flywheels, but you can definitely notice a difference on the street too. | ||

Aaron |

I thought about it, but managed to bite my tongue  He's right, Tim, one of these common inertia dyno's measures spin up time of a known mass and determines hp & torque from that. So lightening anything in the powertrain shows up as more hp. A brake dyno, by comparison, may not show it. Technically, heavy flywheels don't cost power, they just store the energy. For reasons Blake can probably explain better, reducing rotating mass on the flywheels reportedly has a bigger effect than, for example, removing the same amount of mass from the rear wheel. Something about the gear reduction in between the engine and wheel ... and as you go to taller gears, you increase the dyno's mechanical advantage on those flywheels and it shows as more power. And, as Ron would point out, it's all BS anyway. There's no provision in the SAE standard for sweep/inertia testing of an engine's power and correction processes are supposed to include things like oil temp and rotating mass and gearbox friction and the drag of your chain tensioner. It's widely believed that Dynojet applies a blanket correction for drivetrain rotating mass, to make the inertia dyno's results more comparable to a brake dyno's. But of course, whatever they're guessing can't be right for all bikes. But hey, it's a reasonable tool for doing tune-ups and comparing similar bikes. Just don't talk to a real engine guy  | ||

Jmartz |

So Aaron, imagine you had two Buell motors identical in every sense except one had an S2 lower end and the other an S1, and they were both spinning at their peak HP (same rpm), if equal loads were imposed upon them, would the S2 dissipate more energy initially since it had more of it stored in its heavier lower end? In drag racing, would this S2 bottomed bike launch quicker than the S1 if both were released at say 3000 rpm? Alternatively, if both were runing at 3000 rpm, say 60 mph, and full power was applied, would the S2 accelerate slower since it is using some of the chemical energy of the fuel to store it in flywheel spin? |