| Author | Message | ||

Hulkss |

Aaron, Thanks for the photos. If a new gasket fits on the Millenium cylinder, what happens on the engine case side? Won't that side now be as bad as the cylinder was? How about the head gasket? I was shipped head gaskets for a standard bore cylinder. All the holes line up but the gasket overhangs the bore a little. Thanks in advance for your comments. Brad | ||

Aaron |

Brad: good point on the case side! You didn't get the correct bore head gasket? I did ... it's a 3-piece sandwich thingy, .032 thick. Doesn't overhang the bore any. Sounds like you should call Brian, I'm sure he'll fix you up. %*@! happens. Be sure to put alignment dowels in the tops of the cylinders. AW | ||

Hulkss |

The head gasket bag says 3.512 bore. The 1250cc cylinders are 3.563 bore. The gaskets are the three piece sandwich you described. Brad | ||

Jnl |

Hello all, Some of you original SCAB's might remeber us as the Villiage idiot and his wife. Just thought we'de drop a line and say hi bike was down for a year and a half. BAD BAD story regarding keeping factory chain tensioner instead of after market ( if you want a good reason to change I can give you about 500 hundred of them now). The beast is back know putting about 90hp and 90 ft lbs. to the ground, it still needs some fine tuning. Prior build was 78 & 78 at 4500. Now have a delima and need quick answer so I can put back together during the 1st part of the week, going to copper head gaskets: what is stock thickness, and what is safe to put in with thunderstorms without machine work, Fuel not a problem have easy access to 100 octane. Some one please let me know so I get the right thickness ordered :-) Thanks, John & LeeAnna | ||

Jimidan |

The best bang for the buck on roller rockers is the Rev Tech Rollers...I got mine for $300. | ||

Rocketman |

I rang Cometic last Friday and they're shipping me the base , head and rocker(kit) gaskets right now. However, I was told that the head gasket is available at 20, 30 or 40 thou only. Is 30 thou a generalisation of .032 me wonders or do I need to make another phone call ? Rocket in England | ||

Aaron |

Brad: I don't have my gasket packaging, but it measures 3.547 ...  which causes a very minor overhang ...  I looked at one that's been run and there's no sign of contact with the piston. Hmmm ... Rocket: I dunno ... but mine measures .032, exactly what Brian told me it would measure. AW | ||

Hulkss |

Aaron: My 1250 kit head gasket measures .030 inches thick, just like the package says. I've read that when hot the stock cylinders grow about .040 longer. Hypereutectic alloy would be about 85 percent of this or .034. So to get the squish (hot) at .064 the piston would have to go right to the top of the cylinder when cold. I'd be afraid of hitting the gasket with the piston if it overhangs, especially starting up on a cold morning. Have you ever checked how high the piston goes in the cylinder (with no base gasket)? Brad | ||

Aaron |

No, but I set cold squish to .023 and hand-shaped the chamber to match the dome. It's very difficult to measure deck height because the dome goes right to the edge of the piston. | ||

Rocketman |

Well I ordered the 30 and 40 thou head gaskets, so at least I'll have a choice. Not necessarily the correct one, but never the less it's a choice  Bottom line is, we're gonna measure up the whole shebang before rebuild. And let's face it, I've got all winter to get it wrong !!! Rocket in England | ||

Jnl |

Could someone please help explain some about the Cometic "layered" gaskets and what is meant by pigtails, wouldn't ask but got no Info off of Cometic's web sight. Thanks | ||

Aaron |

The Cometic sandwich gasket is what's pictured above. It's 3 pieces, riveted together. The outer pieces are coated with something and it doesn't need viton seals around the alignment dowels, they're integral. I used one gasket for probably 6 mock assemblies as I measured and filed, then used the same gasket through 3 cycles of running it and tearing it down again. No signs of a leak whatsoever. The gasket still looks like new, I'll probably use it again! If you insist on using that Bartel's crap, at *least* coat it liberally with K&W Copper Coat or something equivalent, that'll give you chance of it working for awhile. It's messy and a hassle, though. You're totally shooting yourself in the foot if you just use hylomar on the aluminum shim base gasket like they say. Might work if both surfaces are perfectly flat, but fat chance unless you make them that way. Pigtails are a device designed to reduce the likliehood of a base gasket leak. AW | ||

Hulkss |

Aaron: I spoke to Brian Nallin today about my 1250 kit. I have the wrong head and base gaskets (as suspected). I also had the wrong piston rings but that is another story. He said the proper head gasket should not extend into the bore. The piston edge will go all the way up to the top of the cylinder when cold. Cold squish is equal to the head gasket thickness when a .010 base gasket is used. I noticed I did not have the reduced weight tapered I.D. wrist pins mentioned on his web page. He said that they were discontinued. They have coused some piston failures due to too much flex. KB pistons told me the same thing about Zipper's light weight wrist pins. The pins flex and the pistons crack into pieces. BTW did you ever check the piston/cylinder clearance? I forgot to ask what it should be. Brad | ||

Aaron |

Well, there's lots of tolerance on that squish figure. Cast squish shelf in the chamber, y'know, plus there's tolerance in where the lower end ends up locating the wrist pin in relation to the cases, which I believe is why HD puts so much margin in them, even in the motors with a flat squish band. So I sure wouldn't count on squish being equal to the head gasket thickness. No, I never tried to measure the clearance. Bottom line, I don't have the equipment to do it right, and I think other methods are a waste of time. The cyl needs to be clamped in a torque plate. And read what the service manuals say about measuring pistons. I think sticking a feeler gauge up there is basically worthless. I don't have the tapered wrist pins, either. But I've had good luck with the lightweight wrist pins that Axtell sells, I have a set in my FXR. 88 grams apiece versus the stock 108grams if memory serves. And those waaaay cool teflon buttons. AW | ||

Al_Lighton |

A couple weeks back, Sparky wrote: "On the Palomar VIII ride yesterday Jerry Johnson's White Lightning made a loud metallic clunk noise similar to what you hear when selecting first gear and the engine quit as he was taking off from a stop. Now the starter spins the engine fast with little compression and no fire. Spark plugs look clean, no debris. Finger in the spark plug hole results in little compression at the front and only a little more for the rear. Until the shop tears it down several theories came up and I offered that the cam drive pinion key sheared causing the cam gear timing to go astray." Jerry just sent mail to some of us that were on the ride, the failure was: "THE PINION SHAFT NUT BACKED OFF, AND THE MAIN CAM DRIVE GEAR MOVED ENOUGH TO DROP THE WOODRUFF KEY INTO THE OIL PUMP.. SO NEW OIL PUMP AND A FEW OTHER PIECES IN THE CAM COVER AREA, I WAS RIDING ON THE 2nd ALREADY." So Darryl was pretty close! Al | ||

V2win |

Anyone here know the od of the spigot of a millinium 3 13/16 bore cylinder and the required bore needed in the engine case? | ||

Pammy |

I don't know the bore size off-hand, but I DO know that you shouldn't bore anything until you have the cylinders in your hand. That would be like boring cylinders before you get the pistons...Don't do it, patience is a virtue...and it's cheaper too. Mistakes like that are expensive. | ||

V2win |

I got the same advice from my dad when I told him I was getting married.  He was right too. He was right too. Is the spigot od for the 3 5/8 the same as the 3 13/16? | ||

Jmartz |

V2win: You can get an idea of the OD of the spigot. If the piston is 3 13/16 or 3.8125, with a nominal cylinder wall thickness of .070 (these vary by seldom get thinner than that) that would result in a 3.9525 OD. I bet you the actual diameter is larger and you'll still need to make the case hole slightly bigger. Figure on 4.0?? | ||

Newfie_Buell |

| ||

Newfie_Buell |

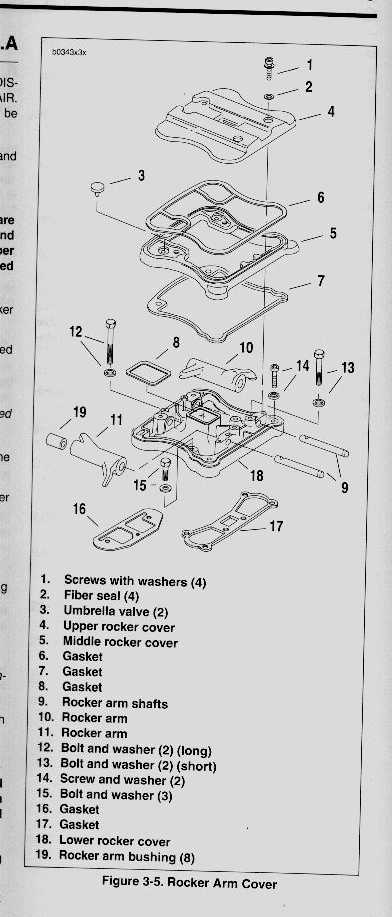

OK, my post did not get attached to the photo. I am planning on changing the rocker box gaskets with the new style steel ones. I am wondering if I have to disassemble all of the above in order to get to the old gaskets. I also assume I am replacing items #16 & #17 with the one piece gasket. If I have to take apart all of the above, when I re-assemble do I have to get the pressure off the push rods/rocker arms in order to torque the bolts to the right specs. This is my first time doing this and any help is greatly appreciated. Bill | ||

Rippin |

Bill, Don't sweat it. Just take your time and remember when you tighten it back down only turn #12 and #13 a half a turn at a time to let the lifters bleed off. Also make sure you have the cylinder you are working on is at TDC with both intake and exhaust closed to minimize any stress. Also I couldn't find in my manual where it said what to use on the bolts as locktite or anything but I did clean up the threads from all the shit that HD uses and primed them with Loc-tite primer and used blue just in case. Hope this helps a litte. Ryan | ||

Blake |

Bill, you do NOT need to separate the rockers themselves (Parts 9, 10, 11, 19) from the box. | ||

Newfie_Buell |

Thanks a bunch guys, Info on the rocker box gaskets is great. This board can be better than a dealer, especially when there is no Buell dealer within 1500km. I am also in the process of polishing the head pipe from tips I also got off this board and it looks fantastic. I will post pics when finished. I am about half way there and it has only taken about two hours so far. Thanks again, Bill | ||

José_Quiñones |

Update on my M3T, ie, my 99 S3T with a stock airbox, muffler, Race ECM, but with M2 cams.... I finished breaking it in, so I have a better feel for it, but have not dynoed yet. Basically, it feels like a stronger M2. I pulls cleanly from 2500 rpm all the way to redline, and is especially strong between 3 and 5,000 rpm, where it used to be in a hole with the stock S3 cams (the X1 cams) It doesn't have the "hit" from 5500 rpm to redline as before, but I don't miss it, because the bike accelerates past the speed limits so well below that that I rarely get to redline! Just seamless acceleration..... Passing on the highway (60 to 80 mph) is as simple as opening up the throttle, no downshifting needed in fifth gear! This is where it is most fun to ride. It's funny to watch the the tach barely move from 3800 to 4000 in fifth gear, but watch the speeds jump past 80mph really quickly. I have no idea what top end HP it has, but I really don't care, it's all MIDRANGE that's fun to use. José | ||

Blake |

Wheelies more easily?  | ||

Jim_M |

Now that does sound like a lot of fun... It'll be real interesting to see the dyno on it. How hard was the cam swap? | ||

José_Quiñones |

Jim, Cam swap was straightforward, according to Chris of HD of Ft. Washington, who did the swap. When I first rode the bike, it would carb fart when cold and surge badly, so we went to the race ecm. This helped but it was still not right. Finally Chris reset the ignition timing (I think he adjusted it until it ran smoothly). I don't remember how advanced it is now. Since then, no more carb farts, and the surging is 95% gone. The only down side is the gas mileage, my warning light used to come on at about 180 miles, now it lights up at 160. I think it's my wrist's fault! Blake, This will shock everybody, but I have never actually tried to wheelie on purpose on my Buell! But the front end has felt light a few times coming out of turns since the cam swap...... I'll probably do a dyno sometime, just to kill my curiosity. I might go to zipper's to do it, HDW's dyno always read low. Maybe I should take it to Aaron's Dyno  | ||

Sportyeric |

Bill. The rocker shafts may slide out if you tilt it. Don't ask how I know. You're not supposed to mix them up. Also, note the notches in them where the bolt goes through. Revealing my true competence level. BTW. It's still raining on the Wet Coast. Any snow your side of the country? | ||

Spike |

Just a quick note: I changed my rear rockerbox gaskets today. I'm shocked at how simple it was. The only part that was even remotely difficult was removing the one allen screw that was directly under the frame. I was able to get it out with a small pair of vice-grips. Total time was right at two hours, including clean up and a quick break to read BadWeB. I used James metal gaskets on the lower section and I used new stock rubber gaskets everywhere else, so I don't expect to see any more leaks. Spike '99 Cyclone AIM: cheetahRX7 |