| Author | Message | ||

Aaron |

My good friend Henrik, the rubber mounting does not allow the swingarm pivot bolts to move relative to the rear axle. The rubber mounts just connect the frame to the engine/swingarm/rear suspension assembly. The frame floats around on there. But the bolts that go through the middle of the isolators are anchored to the engine/swingarm assembly, as is the rear axle. It's a good reference point for alignment, if you can make a tool that's stiff enough (didja see mine at Bonneville?). The easy way is with a caliper like the book shows. AW (live from Tokyo, after spending the last few days in Singapore) | ||

Hans |

Hi Aaron, You was writing from Singapore. That clears up my confusion when I saw your contributions on Badweb just after you announced to leave within 12 hours. Well, my knowledge about modern communications is updated now with normal life experience. Have a nice trip further. Glad you brought up this point as I was unsure about the fact that measuring measuring from the pivot was unnnecessary and because the great distance not the best manner. However: first time I did it following the manual I made a mistake: Did not realize that sides of the moving "shoe" are not exactly perpendicular on the heartline of the fork. They have somewhat freeplay and are turned a few degrees towards each other left and right. Difference between low left and high right about 3 mm. The short pointers of the micrometer makes it difficult to measure over the center of the axle. Used the carpenters eye for precision. Hans. | ||

Aaron |

Yes, Hans, you're exactly right ... it sure seems like there's error in the way the factory wants you to do it because of what you mention. I think referencing it to the swingarm bolt is the most accurate way. But, it's a little tedious to do. AW (now in San Francisco) | ||

Ara |

Guys: I found a couple of hex bolts in my misc junk can that fit so snuggly into the female hex swingarm bolts that they make a perfect reference. That and a 9/16 inch dowel (I think a 1/2 inch dowel would be too loose) through the rear axel and the belt adjustment/wheel alignment task would be a breeze... and no more trying to get both the faces of the head of the rear axel and nut perpendicular with the swingarm. Russ | ||

Rocketman |

Maybe I missed something here but the target you're aiming for is that the rear wheel tracks the front perfectly. You can use a long straight edge that runs along one side of both wheels. Obviously you will have to take into consideration the front is narrower than the rear, but you could very quickly make a "stepped" straight edge or insert pins in it for the front wheel\tyre contact points. This way, it will always keep your wheels in line. Rocket in England | ||

Aaron |

Yes, but that's a different set of adjustments, accomplished by the heim links. The rear wheel needs to be aligned to the engine with the axle adjusters, and the rear wheel/engine assembly is aligned to the front wheel, as well as it's side to side tilt, with the heim links. | ||

Henrik |

Thanks Aaron; slight brain fart on my part. I guess my bottom line is making the swingarm pivot and the rear axle parallel. Rocket; with the straight-edge method, you're assuming the motor/swingarm/rear wheel assembly is correctly aligned within the frame  You can see the tool I mentioned Here. Pricy, but you get the idea. Henrik | ||

Rocketman |

Oh shoot, did I forget about the way this whole assembly hangs in the frame. Now I understand the part I was missing. Like Henrik, my brain farts too  Rocket in England | ||

Henrik |

Aaron - you beat me to the punch ... and - uhhh, thanks Rocket  btw. how about the Aprilia Blue Marlin instead of the Brutale? btw. how about the Aprilia Blue Marlin instead of the Brutale? Speaking of alignment; I took the SV650 up to GMD computrack today. They just opened op shop in CT - about an hour away. I think I've got everything pretty well set up and am interested to see how my set-up compares with their "sweet numbers". Henrik | ||

Rocketman |

Henrick : Last week MCN ran a feature on the Int' Show, in which they questioned a few show go'ers. They printed a small picture of each person followed by a few worded questionaire\write-up from each person to accompany their pic. It filled out the double page. More amazingly, the majority of them said the Blue Marlin was the best bike in the show. What amazes me more is I'd bet none of them would buy one ! It's the fickle face of what we like but we wouldn't dare ride, unless of course, you're like me. The Marlin was fine but the cafe racer style is not my bag anymore. They should build 'em though, just because the biking world needs creations like this to keep it vibrant, otherwise the place would be full of dull Japanese race reps. Rocket in England | ||

Bomber |

All . . . . .I kludged up a version of the muzzy tool over the weekend, and found that, using the caliper method in the manual, and then the swingarm-to-rear-axle method with my Midnight Special tool . . .there was a difference of approx 2mm . . . .. . I have no idea, really, if that's significant . . . . . . . me, I'd grab a blue marlin in a heart-beat, distribution, money, and garage space willing! | ||

Ara |

Bomber: I would think that you would be able to feel a 2mm misalignment. You might get the sense that it "wants" to turn one way more than the other and you might even feel like you're leaning a bit when you're going straight forward on flat pavement. (Beware of false indications due to crowned road surfaces.) I would think that you would need some way to verify that your new tool is calibrated and accurately measures what you intend for it to measure. Russ | ||

Ara |

Bomber, can you reverse the tool left to right? If so and if you get the same measurements, I think you could consider it "calibrated." From there you could use it to verify that the measured lenght of the legs of your swingarm are not equal. Comments, anyone? Russ | ||

Bomber |

Ara . . .tryin to find an uncrowned road in northern Illinois is . . . . .well, tough . . . . Yes, I CAN reverse the tool left to right, if what you mean is install it on one side, and then install it on the other . . . . I can also flip it end to end . . . all I did was machine up a huge trammel compass (anyone who flunked Mr Dogherty's drafting class will remember that) out of alluminum. It's an aluminum piece (a dowel, if you will) that slides into the hollow axle . . .and another that fits fairly tightly into the swingarm pivot bolt socket head. The two are connected by an aluminum shaft that is fixed on one dowel, while the other dowel slides back and forth on the shaft (sorry, Blake, I know I'm pushing it here ), and can be locked on said shaft with a thumbscrew . . . like so fixed slides back and forth ---| |-------------------| |----- I guess it IS time I get a digital camera, yes? | ||

Ara |

AH! Ok, I understand now. Can you use it to identify the cause/source of the 2mm discrepancy you encountered by using the method recommended in the factory manual? I'm REALLY curious about that! Nice piece of work, Bomber. Russ | ||

Bomber |

Russ . . . . . nah, the tool ain't that smart, and the operator is even . . . . .I"ll let that be . . . . . My guess would be manufacturing tolerances . . .same reason those little marks on my chain drive thumper don't line up side to side . . . the cut-outs in the swingarm ARE machined, likely CNC, but, as a guy that used to write manuals for CNC machines, that is no guarantee of accuracy -- no guarantee at all. no, if I find my engine/gearbox combo is crooked in the frame (as I'm sure it is, at least slightly), I'll have to bring out the single malt and scratch my hea, won't I? poor me grin | ||

Ara |

Yo Bomber, I'm a beer guy myself... there's nothing in the world that won't look at least marginally better after a Guinness Extra Stout. But back to the engine/gearbox alignment conjecture, how does one assure one's self that all is properly aligned? You cluge together a nifty tool for that, and you're going to be a very appreciated (and perhaps rich!) man. Your rear wheel alignment tool is pretty inspirational as it is. Russ | ||

Bomber |

I'm thinkin on it, Russ . . . .job one is to figure out exactly what the engine/gearbox/swingarm assembly (way too many years of writing manuasl!)should be aligned to . . . er, to which the . . . . oh, never mind grin | ||

Henrik |

Bomber: picture of your alignment tool would be great - get that digital camera. The trick to checking overall alignment (theory only on my part) is to get the rear wheel perfectly aligned first. Then take Rocket's long straight-edges and lay them along each side of the rear wheel. Then measure how the front wheel is centered between the two straight-edges. If the front wheel is not centered you bring things into alignment by adjusting the length of the front engine tie-bar. Then stick a magnetic angle measuring tool onto the front and rear brake disks - if they are the same angle (with the bike standing up) you're good; if not, you can adjust the relative, vertical angle of motor/tranny/rear wheel and frame/front end by adjusting the length of the top engine tie bar. Hope this made sense Henrik | ||

Bomber |

Henrik . . . . .I'm gonna get the camera this weekend, promise . . . . .but the tools no great shakes, just so you won't be TOO disappointed . . .. you're procedure sounds great! In what direction should the Magnetic Angle Measuring tool be attached to the disks? Vertical or Horizontal. If Horizontal, I don't see how they would work . . . .the only tools I know of have to be sitting vertically (in relationship to the planet) to work . . . . . really need that camera, yes? | ||

Ara |

Where would a home mechanic be able to buy a Magnetic Angle Measuring Tool? That's really what they're called??? Russ | ||

Bomber |

if it's what i think it is . . .you can get a cheap one at Ace (it is the place, after all) it's basically a 360 protractor (round) with a needle that rotates under the effect of gravity, think compass, but, instead of pointing north(ish), the needle will point down, as long as the circular part is oriented vertically (ok, I'll get the friggen camera!) the circle part rests on a littel magnetic base . . . . I use it for leveling my mill and lathe (since they still live on wooden supports, they more around a fair amount) . . . . mine cost under 8 bucks 2 years ago | ||

Ara |

Bomber: Sort of a compass/plumb-bob combination with a magnetic base, I guess. Ace be the place! (They probably keep it in the plumbing section. The last time I was there I was looking for throw-away paint brushes. Think I found it in the paint department? Nooooo, plumbing. Go figure.) ;-) Henrik: Thanks for the excellent instructions. I seem to recall that the factory manual warns the owner away from fiddling with the engine tie-bars. Why, if it's so simple? Russ | ||

Bomber |

OK, Henrik . . .I finally got it (ya gotta be patient with some of us ol' burnouts . . .that last Hendrix concert really took a toll . . . . .) Like Russ said, thanks for the grat instructions Russ . . .they're in teh tool section in my ace . . one of mine is made by General . . . the other sez Ace on it, but in all other respects is identical to the general one . . . . the reason I have two is involved with a moving episode . . .couldn't find the first one, bought the second one, got home, and you know the rest | ||

Ara |

Thanksgiving Blessings to all who have helped me here: - May your turkey not be soggy. - May your cranberries not be saucy. - May your gravy not be greasy. - May you and your family enjoy this Thanksgiving and may fond memories of it warm your hearts for years to come. Russ | ||

Bomber |

Russ . . .thanks for the good wishes .. . .although my family and friends are always very dear to me, this year, they are even more so .. .. . all -- Happy Thanksgiving | ||

Henrik |

>I seem to recall that the factory manual warns the owner away from fiddling with the engine tie-bars. Why, if it's so simple? Bomber: even though it's simple in principle, I can see lots of room for error if it's not done properly. Error in set-up doesn't do well for bikes known to be ridden hard on twisty roads  The full set of instructions can be found in the service manual for the HD FXR; the factory may have seen some problems previously and decided to advice against messing with it. Henrik | ||

Bomber |

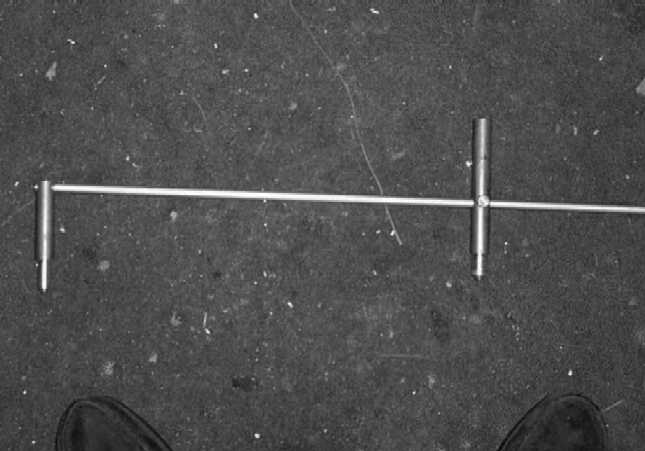

Ok . . .here's a pic of the tool . . . . . the left-hand leg is fixed to the longer, skinny rod, while the rigiht-hand is free to slide back and forth on the rod. . . . it' aheld in place with a locking bolt coming through the top of the leg . . . this is Mk1 Mk2 will see the righht hand-leg shortened considerable, aith the locking bolt going in theough the back of the leg . . . . wish me luck . . .first time pic poster . . .  | ||

Bomber |

woo hoo . . . .it worked! BTW . . feet inclulded for scale (grin) | ||

Henrik |

Bomber: thanks for the picture - great looking tool. Gives me currage to get into building one myself  Suggestion for MK2: making the cones larger with a more shallow angle would make the tool applicable to more bikes and also aid centering in the swingarm pivot bolt. Making the right (adjustable) leg length adjustable would help getting the cones square on the axle and bolt when measuring. Henrik |