| Author | Message | ||

Blakjak |

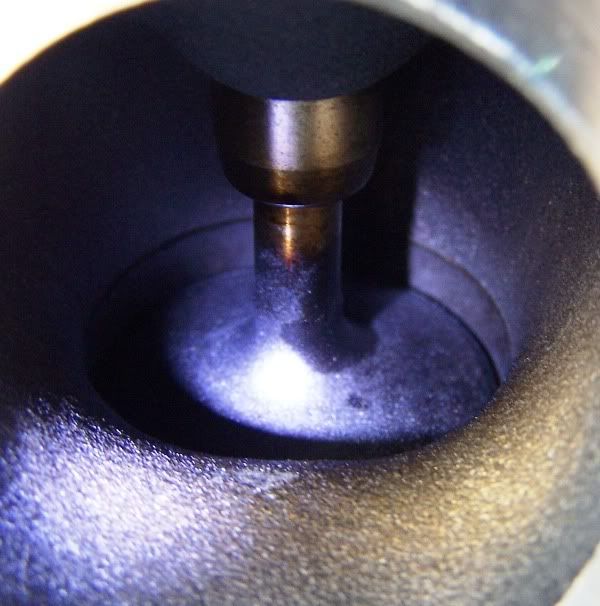

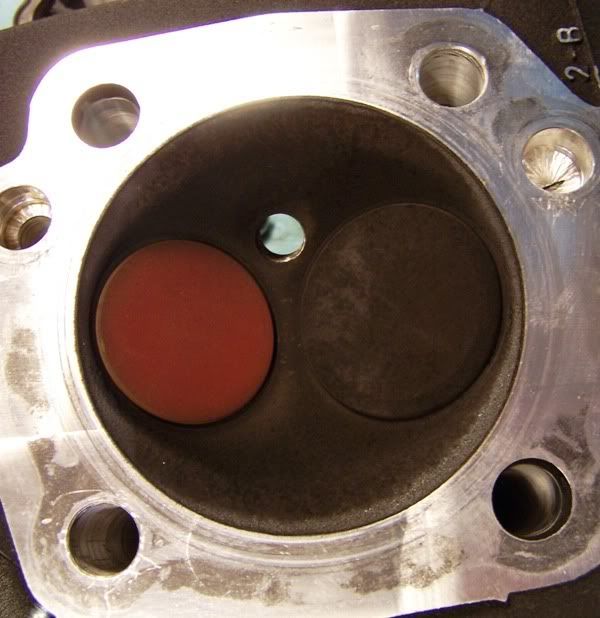

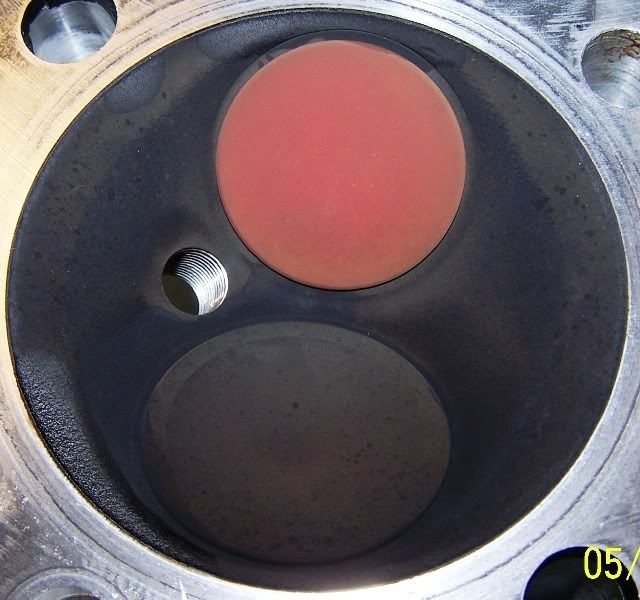

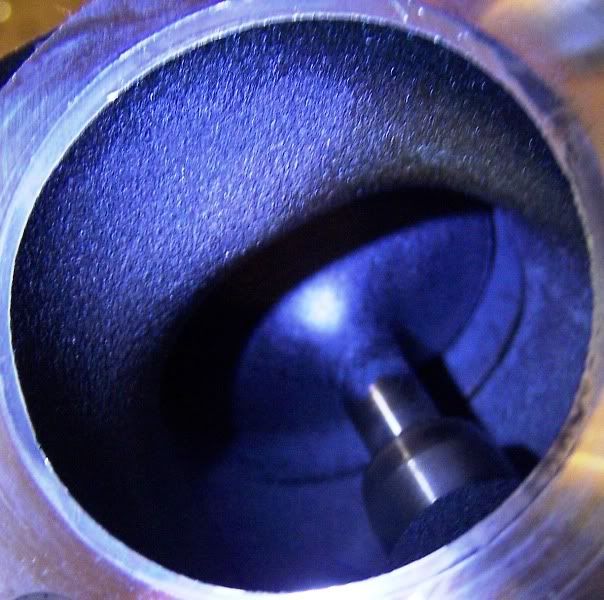

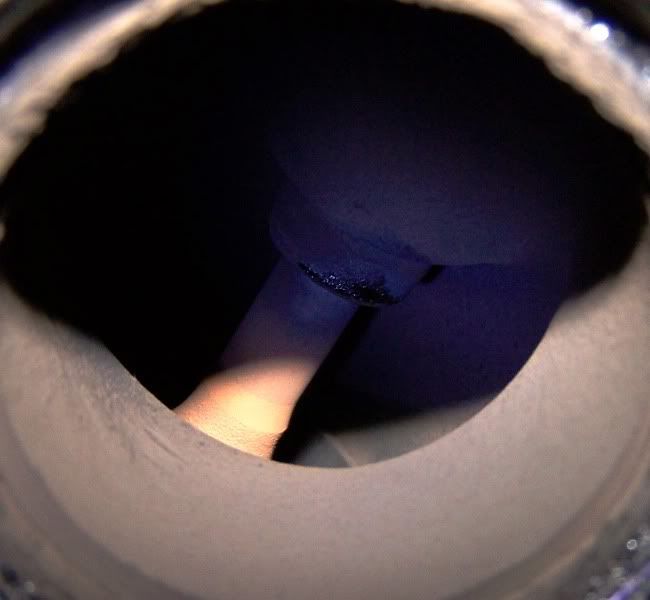

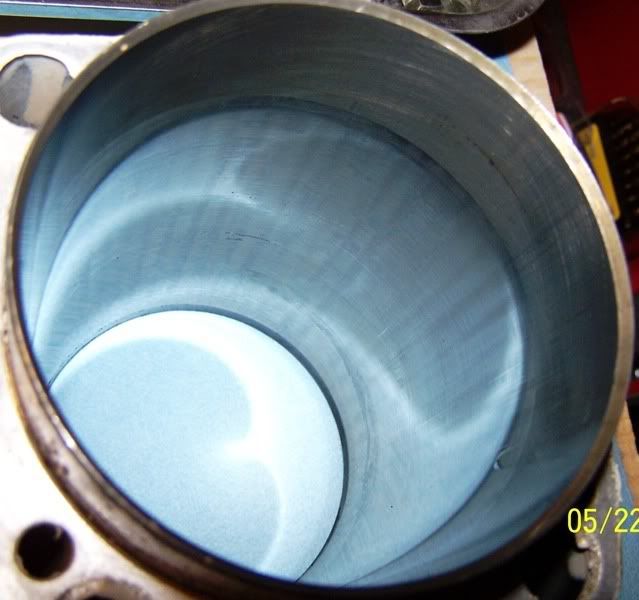

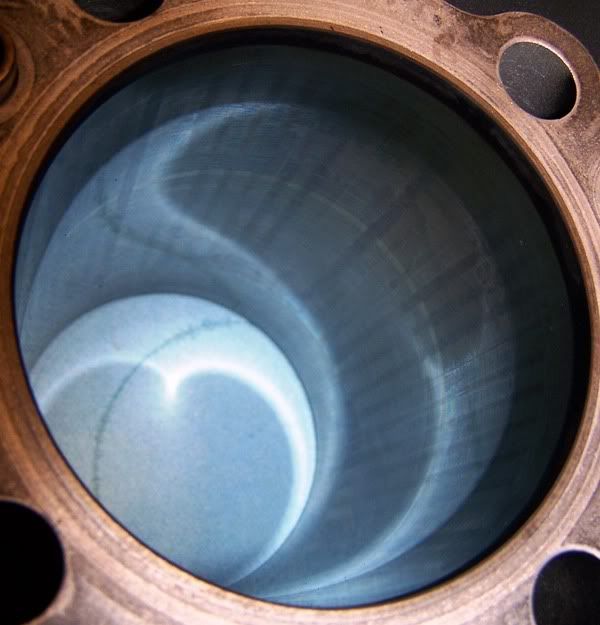

I've got this thread on a few other boards but the only answers I've gotten so far are to get cams with a later intake closing or the rings are bad or the piston to cylinder clearance is too high. 2002 Sportster, 1212, stock thunderstorm heads, .497 cams. Chambers in heads have been matched to 66 cc's. Stock CV carb. Hurricane 1212 Thunderstorm 10.5:1 pistons. Calculated compression is 10.64:1. 340 miles on the rebuild. Cold compression test reading shows 250 psi in both cylinders. Warm (not hot - oil temp @ around 125* on a 65* day) compression test reading shows 225-230 psi in both cylinders. Both of these were taken with throttle held wide open and ran for about 25 cranks or until the gauge didn't register any higher. At 8-10 cranks it would read between 180-190 psi on both cylinders cold or warm. Any ideas as to why they're so high? This causes some pretty bad pinging and it's worrying the heck out of me. Anyone know if stock pushrods are too weak for N4's and thunderstorm heads? The only other reason I can come up with is that the valves aren't being opened all the way on each revolution. I don't know how to check something like that though. The tappets do seem to be pumping up but for the life of me I CANNOT come up with a good reason why and I've talked to a few guys around here who have built their share of sportys and they're all at a loss as well. About the only thing left that I can do is a leakdown test. I have no reason to believe that the rings didn't seal or are bad and with the cranking pressure as high as it is I don't believe them to be bad other than the pressure just keeps going up and up and up for however many revolutions I crank it. I took the cams out today and checked them out and reinstalled them. They are installed dead nuts on. Front Cylinder - you can see the gumminess around the edge of the piston and the tops of the piston pockets. The hard carbon is in the middle right where the firing happens.  Rear cylinder - no chunks of carbon were on this one and I had wiped the edge of this one down before I took the pic. However, the hard carbon was in the center and the gumminess was in the same places.  Front cylinder - after cleaning the piston top, I looked at the cylinders. They look good to me. The front one has the discoloration from a little rust that had accumulated from condensation from sitting outside for a month with no heads on but pistons installed and wrapped in a plastic bag. I took it apart and cleaned it, the rings, and the piston and put them back together. I don't believe it to be a problem.  Rear cylinder - again, it looks good to me. The carbon ring around the top leads me to think that the combustion is happening properly and doesn't leak past the top ring on the piston as that's where it looks to stop at on both cylinders.  I'm all about help guys. How do I check if the pushrods are flexing too much or if the lifters aren't pumping up enough for some odd reason other than just buying new ones and installing them to see if it fixes it? I don't feel like just throwing money at a problem until it goes away and cams are a pretty expensive thing to try on a whim. Would bad valves guides or seats cause this? Again, I can't imagine stock heads out of the box both being bad at the same time with the same problem and the ONLY headwork that was done was .010 was taken off the deck of the rear head. | ||

Pammy |

Blow by(which it looks like you have) or oiling of any kind can cause higher than normal compression readings. Again my guess would be past the rings for whatever reason.I.e. improper clearance, rings in wrong, wrong rings,etc... Milling one head only, to correct the difference in combustion chambers, would not have been the way that we would have done it. We would have relieved the smaller cylinder to match the larger, then milled both if necessary. If the pushrods fit properly, they should be strong enough. Did you replace the lifters when you replaced the cams? You can put the rocker boxes back on without the pushrod tubes and make sure you have the proper tolerances before you do your final assembly. (I am assuming you have the one piece pushrods tubes as well) | ||

Pammy |

Are you hearing a noise(besides the pinging) as well? Why do think the pushrods are flexing. That would have nothing to do with your oiling problem. Also the picture of your front cylinder looks like it has a void about halfway down and on the left side of the pic. Optical illusion? | ||

Blakjak |

The front one has the discoloration from a little rust that had accumulated from condensation from sitting outside for a month with no heads on but pistons installed and wrapped in a plastic bag. I took it apart and cleaned it, the rings, and the piston and put them back together. I don't believe it to be a problem. The valvetrain doesn't sound excessively noisy to me but it is noisier than stock. I know that this will happen due to the SE bolt-in cams. I say pushrods flexing because it's the only thing I can imagine other than the lifters not pumping up. When I do the compression test the gauge ratchets up only 20-25 psi on each revolution. It makes me think that the cranking pressure might be too high and when combined with the valvesprings on the thunderstorm heads compared to the stock 883 heads, the lifters are staying bled down and never pumping up all the way. This in turn won't allow the intake valve to open all the way and keeps in closed longer causing the cranking pressure to just keep going higher and higher. No one around here locally has a solid answer. I'm hard headed and when I get stuck on a theory I hang on to it. I don't think I have blowby unless the too high cranking pressure is causing it. The rings were put in and gapped correctly. The pistons were measured in the bore and have .003 on the skirts as per the manufacturers instructions. The cylinders were honed in torque plates. Granted, the shop who did the boring and matching of the pistons was out of state but they have a good reputation and I have no reason to doubt the quality of work. As far as milling of the rear head, from what I saw it wasn't like the head didn't have PLENTY of meat to shave off as it had a .020 shelf cast in. It was the easiest way to get my squish band and not cause any other problems. Thanks for the replies Pammy!! | ||

Pammy |

the lifters are staying bled down and never pumping up all the way. If that were happening, the motor would be extremely noisy. You have oil in the top end. I can see it in the pictures. If you can feel that 'blemish' with your fingernail, probability is that oil is getting past it as well. Oil in the top end can cause the compression reading to be higher(ask any unscrupulous car salesman about putting oil through the sparkplug hole to raise compression on a whipped engine). It is likely to cause 'pinging' also. It would be interesting to see the rest of the pistons and rings and heads, etc... | ||

Blakjak |

I'll take some pics when I tear down here today or tomorrow. I guess you're right about the noise. I don't suppose it's possible for the lifters to only pump up to the certain point of keeping the pushrods somewhat but not pumping up any more than that? I guess technically that's what they're supposed to do anyways. Hmmmmmm, I just don't understand why both cylinders would read that high if only one has the blemish. No you can't feel it. It's strictly a discoloration of the liner and nothing else. I've been up for about 36 hours now.....I gotta get some rest tonight. I may get it torn down. We'll see. Thanks Pammy! | ||

Pammy |

I will look forward to the pictures. | ||

Pammy |

Oh, and of course you are welcome... | ||

Blakjak |

No pics but did test it out with another tester to see if that was the problem. It seems not. Rear when warm to mildly hot was right at 220 psi and the front was 230 psi. Though this time with the better tester it got up to that pressure in only about 6-8 strokes. At 4 strokes it was at 180-190 psi in both cylinders. Time to tear down. (Message edited by blakjak on May 22, 2008) | ||

Pammy |

Both cylinders look like they are oiling to me. I was just pointing out the blemish in the front cyl as an additional way for oil to come past the rings. Take a picture of the combustion chambers and inside the ports as well if you don't mind. | ||

Blake |

Interesting. | ||

Blakjak |

Huge post of pics - burn the time up. Tore it down. Had an old timer who's been doing this for a while say that using the yamabond if I used too much and somehow plugged up the drain back would cause too much oil to get into the top end and leak past the valves if it got too high. Don't know if that's the case here or not. Would cause extra compression. I am getting quite a bit into the intake from the breather. The lower runner on both sides of the intake itself had a nice film of 20W-50. Anyway, pics. I'm not sorting them into front and rear right now as A) it's a lot of damn pics and B) from what I see, they're awfully close to the same but the differences noted I will be able to say which it is if anyone has any questions or observations. Sorry for the crappy ones. I tried the best I could and I'm not very good at photography or building engines it seems. Good thing I'm in the Marines I guess.                                       | ||

Pammy |

In pic # 15(from top of post) I can see the oil scrapers are lined up and the 2nd ring doesn't appear to be sealing well, if at all. I see even more pits in the cylinder walls (last pic). It appears that you have oil coming down the valve stem in a couple of pics but the amount of oil and the pattern really suggests that you are getting oil past the rings. The scuffing on the pistons looks like there could have been a bit of dirt or debris in the cylinder during assembly. There is also a bit of scuffing just outside of the thrust area (pics 13, 14, 15) as well. You need to have the cylinders and pistons checked for true(cyls) and fitment(cyls and pistons). All of my observations and opinions are based on photographs, of course, so are subjective as such. | ||

Blake |

Nice photos! Is crankcase breather still venting to intake/airbox? If so, try moving it to an external catch can. It is wise to use larger diameter (inside diameter) tubing to avoid added restriction. Also, if breather is still venting to intake tract, is there a chance that you may be over-filling the oil? (Message edited by Blake on May 23, 2008) | ||

Blake |

Never mind, cross posted. What Pammy said. ![: ]](http://www.badweatherbikers.com/buell/clipart/proud.gif) "You need to have the cylinders and pistons checked for true(cyls) and fitment(cyls and pistons). " | ||

Blakjak |

Just got back from the local indy. Pistons, rings, and cylinders check out. Oil passages are clear. Valve stem seals, bad. All 4. From the factory. Absolute junk. Every valve FELL out of the guide when the springs and retainers were taken off. The rubber in the factory seals was so brittle you could press on them with your finger and bend them into whatever shape you wanted and they would stay in that shape. In fact, one of them had been bent when it was put on. Guide clearance was good and checked out with the gauge. New viton (I think) seals (blue rubber w/a spring around them) installed. Going to put back together and check it out again after putting the N6's in. Probably on Sunday as I've got to clean all the old yamabond off now and scrub the pistons, rings, cylinders, and heads down before reinstallation. I'm still up in the air on whether I should run a base gasket now and lose the squish band or just run with what I had. What do ya think? Good lord I hope this was it. | ||

Blakjak |

Fixed. Well, the pressure problem is. Valve seals. Warm/hot readings are now 180-190 max at 6-7 strokes. N6's are in. Gonna go for a ride and see what I can do about the pinging. Got it back on curve 3 for the time being. I'll probably have to end up on curve 4 though. 45 pilot jet at 2 1/2 turns out acts lean now - LOL!!! |