| Author | Message | ||

Reepicheep |

If you are getting a backfire when the power comes back, then it is pretty likely it is your cam position sensor (I keep calling it a crank position sensor, and it is indirectly, but on a Buell it's a cam position sensor). | ||

Greg_e |

His is a 2009, I thought they moved it to the crank in 08??? | ||

Gregoxb |

I believe the culprit has been found: EBR ECM. What appeared to be an intact ECM, was FUBAR. Kudos to Phelan who nailed the problem in one post. Thank you everyone for all your help. I installed OEM ECM and rode around for 30 minutes without any hesitation or stutter. Granted the tune was very poorly matched to my Jardine, but the hesitation and stutter were gone. So let it be known, there was nothing inherently wrong with the motorcycle. Now if someone can answer me a question: why after 3+ years did the EBR ECM decide to turn into a steaming pile of manure, capable of making my bike run like poop and ruining my battery? Physically, the ECM looks completely intact, just like my OEM one.  | ||

Fotoguzzi |

I'll take a stab at that.. even if it looks fine maybe it has the broken solder joints inside under the potting material? was the ECU mounted in the stock place or had you relocated it? if it is I think it can be repaired. | ||

Gregoxb |

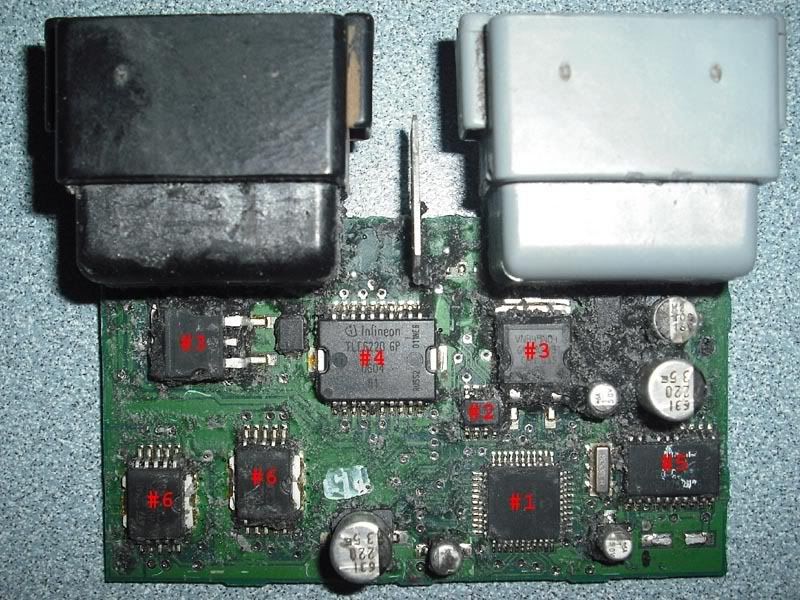

That is how the EBR ECM was mounted and that is currently how my OEM ECM is mounted. Is that bad?  That's the EBR ECM. It can be repaired? | ||

Fotoguzzi |

Reepicheep, Teeps, Ulyman or others will know.. that is not how mine (ULY) is mounted.. so pressure from the seat can break the connections inside (as I understand it) is your seat contacting the wire loom going into the ECU? are you a heavy guy? I'm 150# so far no problems. (Message edited by fotoguzzi on September 19, 2015) | ||

Gregoxb |

You can see on the left cable there is an indent from the seat. (Message edited by gregoxb on September 19, 2015) | ||

Fotoguzzi |

I don't feel qualified to advise but I think that might be enough to have fractured the delicate connections inside the CPU.. waiting for the real knowledge from the others on board.. | ||

M1combat |

Can he take the tune from the EBR ECM and flash it to the stock ECM? | ||

Reepicheep |

I'd agree. The witness marks on that cable bundle suggest to me that cable was being loaded by the seat. That will break the pcboard inside the ECM over time. It can be repaired. The electrical part of it is pretty easy (big soldering iron and good solder). The mechanical part of it appears to be the harder part, you have to dissect the case and the potting to get down to the electrical part. Definitely worth doing in your case though, that's a $300 ECM. | ||

Gregoxb |

When I dissect the ECM, I will be able to see a broken pcboard? | ||

Greg_e |

I've opened one before, not too hard. But I didn't try to put it back together again. Most likely it is broken solder joints at the connector, the soldering is the easy part. And no, I don't think you can retrieve and flash the race data over to the stock ecm. I think I used a small round cutter in a dremel. I'll give it a go if you want, but only if the potting compound is still the black rubber material. If they went to epoxy, all bets are off. | ||

Gregoxb |

I'll give it a go, I will post pictures on my progress. | ||

Greg_e |

Just make sure you don't cut too deep. Then make a plastic or bamboo scraper to kind of get under the rubber to scrape it away. You may need a small wire brush to clean up the solder joints good enough to solder. Best would be to suck the old solder away, but you risk the connector with the heat. Next best is just add a little fresh solder to each joint. Make sure the solder is completely liquid at each joint. You can spread out the heat by working on alternating sides of the connector, or even alternating between the two connectors. That would let the plastic recover a bit between each heat cycle. I hope it is all this easy. And glueing it back together is going to be the hard part, would be nice to make it water resistant again. Do not use regular rtv rubbers! Most of those cure with acetic acid, this will corrode everything. Only electronics safe rtv can be used, or some of the other electronics grade rubber potting compounds. | ||

Greg_e |

Also, do a search here, I'm pretty sure I posted pictures of the inside of an ecm after most of the goo had been cleaned away. I should still have that ecm at work if you want to wait for pictures. | ||

Gregoxb |

Jesus, I was in no way expecting that many steps. Greg-e, if I send the ECM your way will you take a stab at it? I will compensate you for you work and time. It's worth it to me even if you fail. | ||

Brother_in_buells |

On almost all Ulysses and lighting buells the seat is pressing on the wires or ecm. For the lighting seat you can cut some of the ribs away to make more room for the wires and such. | ||

Greg_e |

I'm just going to drop the links, don't want to mess with the image tag thing. http://img.photobucket.com/albums/v329/Greg_E/ecm1 .jpg http://img.photobucket.com/albums/v329/Greg_E/ecm2 .jpg http://img.photobucket.com/albums/v329/Greg_E/ecm3 .jpg http://img.photobucket.com/albums/v329/Greg_E/ecm4 .jpg | ||

Fotoguzzi |

I'll do it for ya, all you do is paste the IMG link     | ||

Reepicheep |

You don't need to pull off everything, it's likely cracked where the external connectors go through the PCB. So just excavate about 1/2 inch back from the connectors on the back. Bamboo kabob sticks from your local grocery are great for all sorts of jobs like this (and cleaning carbs)... | ||

Gregoxb |

Wow, thanks. Nice pictures. I'm still intimidated though. lol (Message edited by gregoxb on September 20, 2015) | ||

Gregoxb |

While I build up enough courage to dissect my ECM, today I modified the position of my ECM for more clearance under the seat. I smeared some electric grease on the cable and identified where the contact was being made:  Next I used a dremel tool to grind the spots were contact was being made. I pooked through to the foam and backed off. But you can see the grease still smeared in a few places:  I realized I needed more clearance. I noticed there is about 1cm of unused space bellow the OEM ECM mounting. I removed the battery tray and modified it so that the ECM would sit deeper below the seat.  I used a blunt chisel and mini sledge and placed the tray on a vice and whacked the ECU mounts down about 1 cm. Then I bent the holders back upright by pressing it against the concrete. Then I used the dremmel tool to cut out bilateral gaps at the bases of the mounts so that the ECU could slide in. Once I mounted the ECU in the tray I bent it with my hand to get it to sit straighter:    Here is what it looks like mounted:        As far as I can tell, there is clearance now. (Message edited by gregoxb on September 20, 2015) | ||

Greg_e |

Either something is wrong with your ecm construction, or they changed to dual circuit boards. Look at the height difference between the two connectors. I didn't catch this before, but it might make this job harder. I would have said cut the bottom off, but now I'm not certain. When I took the above ecm apart, it was assumed to be dead and sacrificial. Since you want to save yours, this might be harder. I'd start cutting near the bottom, just make absolutely certain you do not cut too deep or you could damage the board. Pull the bottom off and see if both connectors are soldered there. If not then there might be a second circuit board in the top of the plastic requiring another cut. Again, I'll take my best shot. Might throw it in my mill to give better depth control and a cleaner edge. I'm not too far away, and USPS should make it cheap enough. That said I have a new cycle I'm picking up this week, so my time may be divided. | ||

Gregoxb |

The ECM in those pictures is my OEM ECM. The EBR ECM looks identical to it though. I was not aware that they changed the configuration of the ECMs throughout the years. I am thinking now, that since the design of the '09 ECM is different, maybe it is not an issue caused by pressure contact from the seat. It is no doubt an issue with the ECM though. A fellow Bueller out here has told me that he has seen 10 or so EBR ECMs go bad. He did not specify that it was from contact with the seat though. He just said that the EBR ECMs are terrible and problematic. (Message edited by gregoxb on September 21, 2015) | ||

Gregoxb |

Well, instead of wasting anymore time I went ahead and ordered a new ECM from these guys http://idspd.com/xcart/ I would really like to repair mine, but I don't know if it is even possible, and these beautiful riding days are flying past me. | ||

Greg_e |

I replied to your private message, go ahead and send it to me añd I'll see if there is anything that can be done to fix it. Wish I had an engine simulator for these, would make trouble shooting so much easier! Guess I should go back to the microsquirt archives and build a simulator. | ||

Readyxb |

Yes, the DDFI-3 ECMs use two multilayer PCBs, one folded back over the other, connected via ribbon cables. | ||

Greg_e |

Thanks, that will help with trying to get it out of the plastic and rubber. | ||

Gregoxb |

I installed my new ECM today. Niiiiice tune. Bike is back to 100%!!!!! Greg_e, I went with a new ECM because I did not want to wait anymore. This past week while my bike was down I missed too many good riding days! Thanks everyone for all your help! | ||

Greg_e |

Assuming you still have the defective one, I'll still try fixing it if you want to send it. Might get a spare, might get a desk decoration. |