| Author | Message | ||

Schwara |

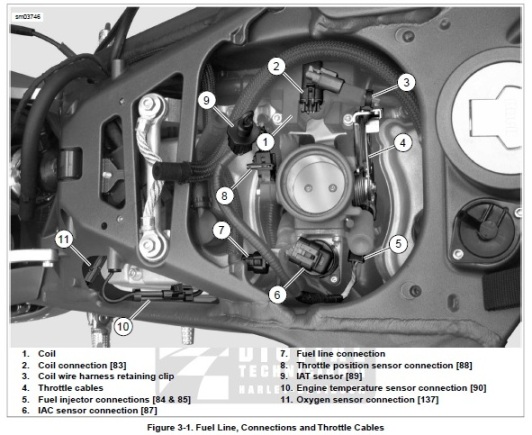

As the title implies I'm in the process of doing my very first engine rotation on an '09 Uly XT. I'm very hesitant as this is the most involved repair / mod I've ever done to date. I have numerous cheat sheets downloaded (although only 1 with pics) and I hit a snag last night. I need to disconnect my O2 and head temp sensors before I start lowering, but my layout is different than my tutorial and the descriptions aren't that clear. This pic has the two plugs circled.  I found nothing in that area but I did find this  The manual show a slightly different location than my cheat sheet and that is how I found 1 of the 2, but still can't seem to find the other.  So my first question is, what plug did I find? Next question, where is the other? The top down on my actual bike is shown below.  My last question would be in regards to notes after this step in one of my cheat sheets. It states "All other electrical/fuel connections are untouched, though you may need to cut a tie wrap or two. Pull the tie wrap support right behind the steering head out of the frame with a screwdriver." I don't know what tie wrap support this is referring to. Any thoughts and suggestions greatly appreciated as I will start lowering later tonight. Reep has already been coaching me on the side as well as Al and I really appreciate both. | ||

Schwara |

Well the wiring might have to wait because I can't even break the front isolator engine bolt loose. I've been hammering away on my allen wrench for 30min going up & down with the scissor jack and it has not budged. Any thoughts or suggestions? | ||

Sifo |

Piece of pipe on the allen wrench for leverage. | ||

Schwara |

Thanks Sifo ... the only thing I could find in the garage was aluminum and I bent it. It wasn't very thick. I'll run by the hardware store tomorrow and find myself a nice good ol fashioned steel pipe. I also hosed what I could see of the bolt down with PB Blaster in the hopes that maybe a little could get up in those threads. We'll see. Thanks for the response. | ||

Ducbsa |

Try using the hole in the end of your biggest crescent wrench for leverage on the allen wrench. | ||

Schwara |

Thanks a lot Duc that did it. | ||

Schwara |

I started lowering to look for my last missing plug (head temp?) and it looked like the Coil was going to hit some kind of plastic wire guide on the left inside of the frame. I just went ahead and disconnected the plug wires and pulled the Coil out. Started lowering and then noticed that the steel tube wire guides for the throttle cable were also eventually going to hit that same plastic wire guide. If you look closely in my top down pic (above) you can see the shadow of the Coil on this plastic wire guide but I'll also attach close ups below. I can't recall reading about that in previous posts but anyone have experience with this? Do I need to remove the two plastic fasteners holding the wire guide to the inside of the frame or can I potentially loosen the connection on the steel tube wire guides for the throttle cables so maybe they can hang limp until bolting everything back together once again? Pictures below show the plastic wire guide on the left inside of the frame and the two plastic fasteners are circled. You can also see the two steel throttle cable wire guides just above this in the 1st picture.   | ||

Sifo |

I've only rotate my engine once, but IIRC I removed the coils and disconnected the throttle cables. Both are pretty easy to do, so I would get them out of the way. | ||

Schwara |

Thanks again. I'll take a look at the throttle cables tonight. | ||

Schwara |

Thanks Sifo. I loosened the jam nuts on the throttle cable guides and they went slack so moving them around a little was no problem. I also went ahead and worked out the 3 (not 2) plastic fasteners in the plastic wire guide shown above (the 3rd was underneath) and then I got the engine low enough to pull off the headers ... finally. Strangely, the engine didn't seem interested in going much lower however. I can tell that even with the 3 fasteners out of the plastic wire guide and it now being able to move around, the left side of the engine still makes it tight squishing that plastic wire guide against the inside wall of the frame. I don't know if that is my issue or if it is somewhere else. I'm curious if it might also be belt tension? Some cheat sheets I've read (& the manual) say to remove the belt tensioner and loosen the rear wheel, but others don't mention this at all. I'll investigate further after the long weekend. Meanwhile, my pipe is off to Jet Hot. (Message edited by schwara on May 23, 2013) | ||

Schwara |

Oh, and as another update (for completeness) I did finally find my errant remaining cable/plug. It was in fact the cable for the head temp sensor (braided in pic) and it was hiding in this other plastic wire guide.  I had to unscrew the little bolt for the guide, unweave the various cables, found & identified the wire to the head temp sensor, and then tracked it down to where the plug was. I still can't reach the plug yet, but once the engine is a little lower I should be able to get to it. Ironically, this plug that I never could seem to find was on the opposite side of the bike (left) than what was shown in the manual pic I attached earlier. The plug was also so far down that there was no way I could have seen it without following that braided cable all the way down. I couldn't even snap a good shot of it with my cell phone camera ... sorry not motivated enough to go grab a real camera. | ||

Sifo |

That will be the one your forget to plug back in!   | ||

Schwara |

If I only forget 1 thing I'll consider myself lucky  The main reason I am documenting everything with pics is for my own good. I'll make a check list with the pics & then go in reverse after the projects are done. Hopefully that will work. My failures will be well documented if it does not.  | ||

Schwara |

No joy ... apparently I have an engine with the ability to defy the effects of gravity. I have gone up and down multiple times and the the engine will make it about half way to the front tire and then stops ... while the scissor jack keeps lowering. All wires, bundles of cables, and even the plastic wire guide (which apparently has 4 plastic fasteners, 2 top & 2 bottom) are loose and not binding. I hear nothing rubbing going up or down and the engine will wiggle side to side slightly while down. I went ahead and raised the rear tire off the ground using ratchet straps on my luggage rails to get the belt as slack as possible ... the engine went no lower. I have no other ideas besides pulling the rear wheel completely off to make sure there is no tension at all from the belt. I also have my FS belt tensioner pulled in all the way to allow a little slack in the belt from there. I kept checking the belt tension each time I went up and down and it never felt super tight. Does anyone have any other thoughts, suggestions, or opinions prior to me pulling the rear wheel off tomorrow night? | ||

Andersonhdj |

So is your belt still on the pulley? I slacked off my rear axle till the wheel cleared the taper in the bolt , moved forward and released the belt completely. I also missed the tie bar to the rear head which had me stumped for a moment! Also released the pinch bolt on the swingarm spindle at the rear of the motor. | ||

Schwara |

Yes, belt is still on the pulley. I thought I read a cheat sheet or two from people who didn't even mess with the belt but maybe they were only doing the headers and didn't need to. Pretty sure I got the tie bar, but I'll double check that I got the right thing. The pinch bolt is new to me. That might be my issue. I don't remember reading about that so that could very well be it. Tonight, I'll start with the pinch bolt, check the tie bar, and then go ahead and loosen the rear wheel for good measure before I try again. Thanks a lot for the suggestions. I appreciate it. | ||

Schwara |

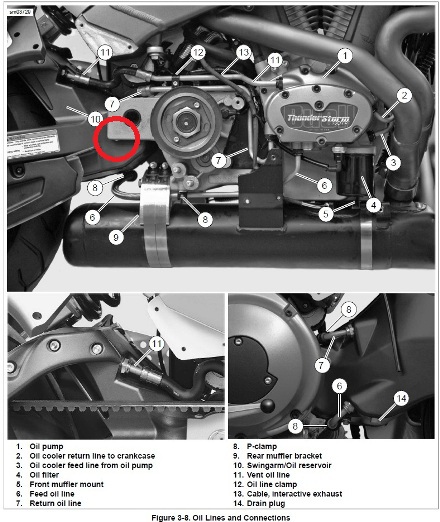

I wish I would have looked at the bike in person before work this morning, but from this picture from the manual is the pinch bolt mentioned what I have circled in red?  Thanks again. | ||

Schwara |

The manual also mentions loosening (not removing) the rear isolator bolt. I'm not sure if this will make any real difference or not with my current issue since the rear tie bar support is no longer connected to the rear head. Does anyone have experience or thoughts on that one? (Message edited by schwara on May 30, 2013) | ||

Andersonhdj |

That's the one. Theoretically it should'nt make a huge difference but you are trying to rotate the motor against the shock spring in effect. I may also have slacked off the swingarm pinion a turn, can't remember right now! I just removed the isolator completely to gain clear access. Also there's no need to completely remove the rear axle, just back it out till the wheel clears the taper then remove the belt from the front pulley and let it hang. | ||

Schwara |

That's a good point. Thanks again. I'll go ahead and back out the rear axle, release the pinch bolt, and then I'll see how far down the engine will go before playing with anything else. | ||

Andersonhdj |

Hey fella, i'm feeling a bit brain dead,if i loosened the pinch bolt then i had to have loosened the pinion otherwise it does'nt help to loosen just the pinch bolt. It's the same size key used to loosen the axle bolt. Sorry for the confusion,medication makes me a tad slow sometimes, specially the memory of late. Spinal degeneration. | ||

Schwara |

Thanks for the update. I'll have to look up what the pinion is as I didn't completely know this one when you mentioned it before. I'll check it out in the manual. Thanks again. | ||

Greg_e |

Did you crack loose the swing arm pivot? Did you remove the tie rod that connects on the belt side of the bike just above the front pulley? Those are the only other things I can think of that need to be done, I don't even do anything except the front most plastic fastener. The harness has enough play to just let it down, same with the throttle cables, but make sure the clutch cable is free. | ||

Schwara |

Thanks for the input Greg. The tie rod is off and I will be taking care of the swing arm pivot pinch bolt shown in my pic above in just a few minutes ... assuming that is the same thing that you are referring to. I'm also in the process of pulling the belt off just to make sure it's not adding extra tension in the system as well. Sadly, I just got my pipe back from Jet-Hot and it looks great. Too bad I'm not ready to put it back on yet. | ||

Schwara |

OK, so I got the belt off the pulley and released the pinch bolt. The engine did come down more than before, but once again stopped before lowering all the way to the front tire. I looked all over for things binding or wires stretching but saw nothing. It was late and I was tired so I decided to call it a night before getting too frustrated. I was thinking that I probably have enough space to get my work done so instead of waisting even more time I figured I would just deal with it the way it is. I cleaned everything up for the evening and turned in with a book and a beer. While I was sitting in bed I was going over everything in my head and then it occurred to me that maybe my new stop had nothing to do with cables. I went out again and looked and sure enough the back of the case looks like it is resting against the footrest support plate. I didn't get a new pick but this was the gap I had previously and now there is no gap.  I raised it back up a little and tonight I will go ahead and pull those off as my last effort to get the engine a little lower. Whether it works or not I'm going in. Wish me luck and thanks for the help and suggestions so far. | ||

Livers |

Good luck! I don't have a Uly, but my Firebolt manual has that as step 16 of 25. | ||

Schwara |

I know ... I know ... it's one of those steps that almost all of the cheat sheets that I've read have left off. I have a feeling that engine rotations are more common for headers and plugs as opposed to gaskets and for those there is plenty on room & you don't need to go as far. Far the rear gasket, in my humble opinion, I can use all the space that I can get so I probably should not have skimped on the steps. | ||

Schwara |

OK, new rules of thumb ... for me at least. When working on the header and plugs I don't need to mess with the belt and footrest supports, but if I need to get to the rocker box gasket or fan then I might as well. I pulled of the supports tonight and then the engine went pretty darn low.  When it finally did bottom out again I could have potentially loosened up a few more things, but I think I'm OK. At this point there is a bolt on the underside that is resting against the oil line. I think I'll leave that one alone and get to my repairs.  | ||

Greg_e |

I think I know what is happening... It looks like you have both wheels up on jack stands. When you swing the motor down the rear wheel needs to be able to slide backwards because the engine is pushing the swingarm backwards. Be very careful working on this with the engine hanging this way. I think I might lift the engine back up until it takes the weight off the stands, and then carefully lower one end so it can roll. Then try rotating the engine again. It should rotate down to where the head rests on the front tire, if it is anything like my 03 9R. | ||

Schwara |

That makes perfect sense. Wish I would have thought about that in the beginning. I've been slowly moving jack stands as I have slowly gotten the engine lower. |