| Author | Message | ||

Tq_freak |

Hey guys. I posted this on the Quick board too. Well it finally happened to me and I popped a stud on the XB. Does anyone have a stud tool they would be willing to lend me. I'll cover shipping Thanks in advance | ||

Xxxue |

jims harley tools makes the drilling fixture for drilling out the broken stud with the head still on the bike. http://www.vtwinmfg.com/webapp/wcs/stores/servlet/ ProductDisplay?storeId=10101&catalogId=10102&langI d=-1&productId=3295340 | ||

Tq_freak |

thanks, I found that one but was trying to get out of dropping 100 bucks on a tool I probably wont use very often. Looks like I am just going to make my own. | ||

Reepicheep |

I tried that with an old exhaust flange I had left over from the M2. I just welded a few nuts over one hole in the flange, then hit them with the drill press. It almost worked. I had two (related) problems with it. 1) The hole location wasn't quite as precise as I needed. That flange actually has a lot of play in the stud holes, so it's hard to line up when you bolt it on the surviving stud. 2) Once bolted there, it wants to walk when you start drilling. You are in an awkward position. The solution I think is to align and index the holes based on the opening for the head, not on the "other stud hole". This is what the Jims tool does. This makes fabricating the tool more difficult... and makes the cost of the Jims tool start to look less irrational. Probably better to start with a raw plate of steel, basic measurements from the head for distance between studs and the exhaust port and cut a jig. If the exhaust port from the head is a perfect circle, perhaps you could weld a washer or a short section of pipe of some kind if you have the right diameter. Or maybe some epoxy putty... First, weld on a big post "about in the right place" for the broken stud. Then put the putty on your plate with the stud holes drilled, cover the other side of the putty with heavy plastic wrap, bolt it down with the surviving stud, then let it harden. Then take the "imprint" left to both find the center of the broken stud to index your other hole. That lets you locate the precise center of the other stud. Then grind that bit of the epoxy flush, but leave the header exhaust port imprint to hold the jig in place while you are drilling. I have a broken head in the garage, I ought to try and build a tool. | ||

Hogs |

http://www.ebay.com/itm/140910484607?ssPageName=ST RK:MEWAX:IT&_trksid=p3984.m1423.l2649 will that work its 140910484607 Item number: or maybe a cheap run off?? | ||

Bumpnzx3 |

Maybe it's just me- but I wouldn't want to try that one. Seems brass is a poor choice as a guide. I would think the bit would cut into that somewhat easily. I bought mine from George's garage- much cheaper than Jim's if I remember correctly. Worked perfectly. http://www.georges-garage.com/ | ||

Reepicheep |

Its bronze, and only the head of the drill should be cutting... Looks cool, I'm ordering one. | ||

Hogs |

And I wd. think its not something ya wd. use alot so it should last even for just ONE if it works pays for itself...LMK how ya make out Reepichccp may follow as well.. | ||

Bumpnzx3 |

Brass/bronze- both are kinda soft. The tip would be doing most of the cutting. However, it doesn't drill quickly, so it's going to be riding on/against the bronze for quite a while. It's not that long of an insert, so it's still easy'ish to get the drill tilted one way or the other and riding against the insert. Opinions are like butt holes- everyone has them, and they all stink. Hahahahaha. I'd prefer the option that's more or less the exact same as the Jim's tool, but a fair amount less money. | ||

Xxxue |

I won't risk ruining the head to save $70, you really should have a hardened drilling bushing in the fixture, not a bronze guide, go with the Jims Tool, don't trust a cheap knock off. | ||

Reepicheep |

The first time I did it I drilled it freehand with a hand drill. The second time I welded up a jig with an old bracket (that worked worse than free handing it). So my bar is pretty low.  I already have left hand drill bits, I'll be using those with this. Hopefully I'll never need it anyway. My beef with the Jims tool wasn't so much the cost (fixing a busted header stud for $100 is a bargain), it was always that I never had the patience to order it and wait a week to put the bike back on the road. So I always end up rigging something. $100 for the Jims tool just to let it sit in the tool box is a bit high. But for $30 I'll try it. Now that I think about it, I have a perfectly bad head already sitting on the workbench. I'll shear a stud and try this thing when I get it and post pictures. | ||

Greg_e |

That's funny, looks just like the one I designed and tossed on one of the 3D printing sites many months ago. Some of you may remember that thread. | ||

Bumpnzx3 |

Xxxue- that's exactly what I was saying as well...the insert should be hardened. The unit I bought from George's uses a hardened insert. If it weren't for the logo etched in it, you couldn't tell that difference between that and Jim's (I've seen both)....and it's about $30 cheaper than Jim's. Not as cheap as the eBay option- but the same materials as Jim's. | ||

Reepicheep |

I don't remember that Greg, I must have missed it, but good on you. Great idea! The ebay one is polyurethane... which I don't think can be 3d printed yet. Though I don't know if polyurathane is stronger than what the 3d printers can use (Nylon? ABS?). But for sure he could have 3d printed the part to make the mold that he then uses for the polyurathane. Anyway, it's great to have a $30 option in the tool box, even if it only works once. I'm not that worried about the bronze bushing... I expect it will last fine if I am careful, and it's not like I am buying this as a shop tool that I'll be using every week. I break a stud about every 30,000 miles of buelling.  | ||

Tq_freak |

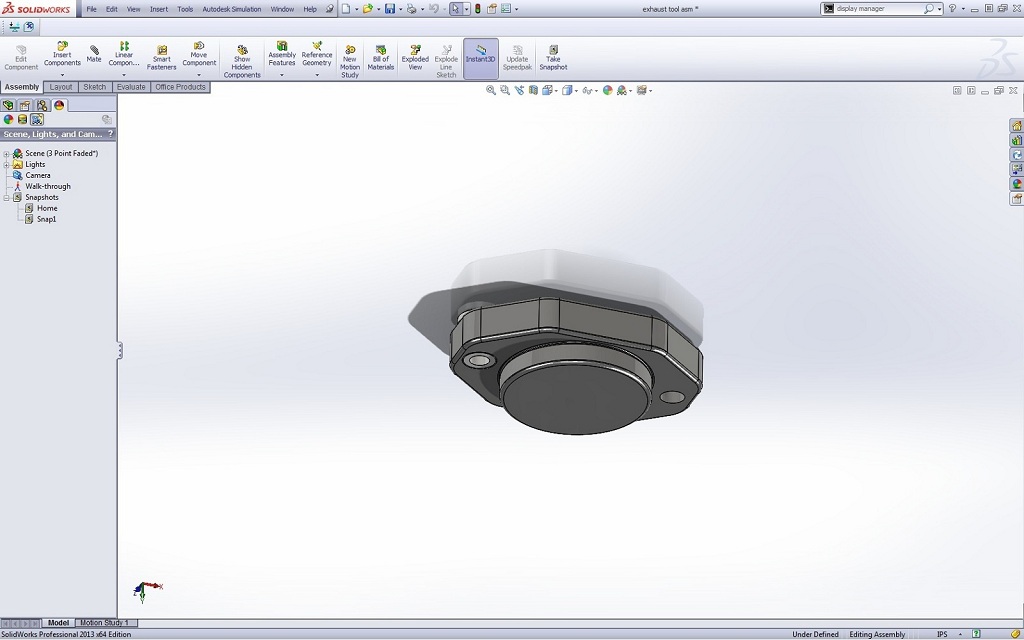

Hogs that looks great might have to pick one up. I had looked ebay quick the other night and didn't find that one. I had given up and ordered the drill bushings from Mc-master (should be here at 10) and my Boss ROCKS and I drew one up and CAD and just printed it in PC plastic on our rapid prototype machine. For what it does the bushing will do all the work, if any and its think enough to support and locate.  | ||

Xxxue |

The plastics used in the process are very weak and wan't support the bushing properly, it will also deflect or distort when tightened down and drill pressure applied. | ||

Reepicheep |

Looks like a good excuse to play with sand casting aluminum! (I doubt it would work, but i've been looking for an excuse to play with sand casting aluminum. I have a few places that I haven't burned yet.  ) ) | ||

Greg_e |

A sand cast would be find if you clean it up a little after the fact. I do have a design that I will eventually make on my milling machine out of billet aluminum. | ||

Tq_freak |

Xxxue - Actually you couldn't be farther off. I undersized the bushing hole by .004 and it pressed in perfectly. This is printed in PC or poly carbonate plastic and not the cheap ABS the original printers printed in. I use it for weld fixtures and Jigs all the time and it machines well and takes a LOT of abuse before it melts or breaks. So far it looks like its going to work well. I just need to get the header off the bike and see if it actually fits. | ||

Greg_e |

Poly carb will be fine as long as the bushing doesn't overheat and you don't let the drill slip on an angle and crack. I machine stuff out of acrylic all the time, great stuff to work with. Acetyl/Delrin would also work for more than a single job, if you are careful it might last a lifetime. How much can you sell that PC printed version for? I can think of a few of use that might want one, it would save me about 3 hours of machine time to cut one out of aluminum (very small mill). | ||

Nillaice |

i see that i'm weeks late for the OP, but for anyone on here; i've got a jim's exhaust stud drill jig tool to loan. just send me a PM and i'll hold your paypal deposit. | ||

Reepicheep |

Looks like I forgot to finish the transaction on ebay before... I really ordered it this time. I have an old head on the bench already... I'll shear a stud and see how this plastic tool and bronze bushing works. | ||

Tq_freak |

Hey all Didnt forget about this, just been super busy and haven't gotten to it yet. I had the CR apart at the time this broke doing the valve maint and had to get that back together first. I have the XB on the pit stands now and will hopefully have it apart tonight and will know rather quickly if this tool will work or not. As for selling them..... Not sure that will fly, My Boss was very leery of the idea. He let me make one for myself as a favor. |