| Author | Message | ||

Obiewan |

My XB12R 2004 has always had problems with the start relay and light relay just under the fairing (left side). I have the fix for it, will soon post pictures if you want to see how I did it. Nothing special, but a few tips I have will make it easier to accomplish. The average Joe can do it with a small file and a little time.  | ||

Brother_in_buells |

Yes show us your tricks! Thanks, | ||

Obiewan |

Will do. I need to take the pictures off the camera. I'll post them this week sometime. Nothing special, but I feel better now that I know I don't have to replace the entire relay box thing. It can be repaired, all of it. | ||

Obiewan |

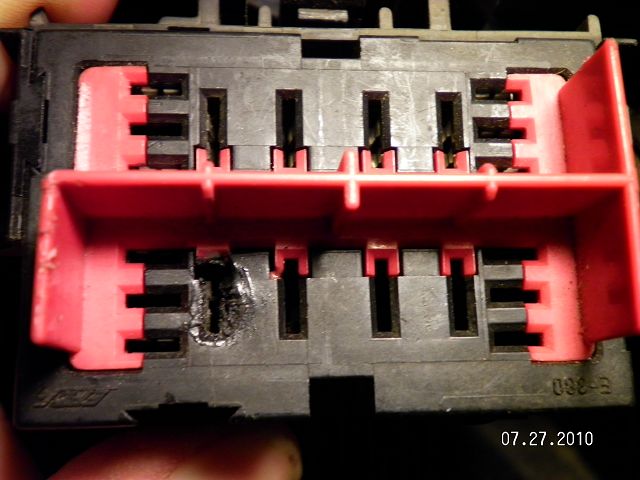

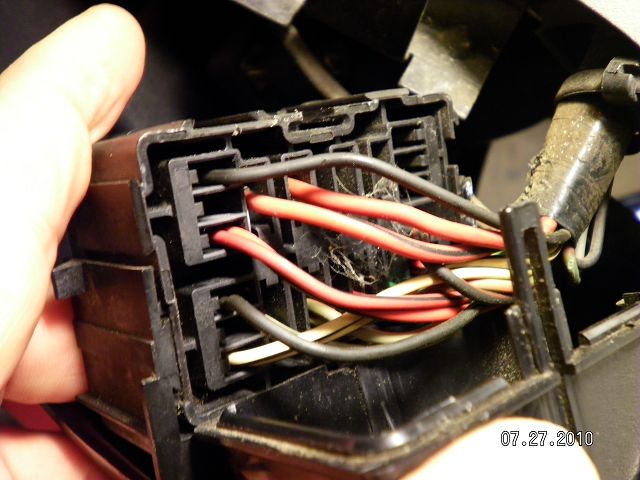

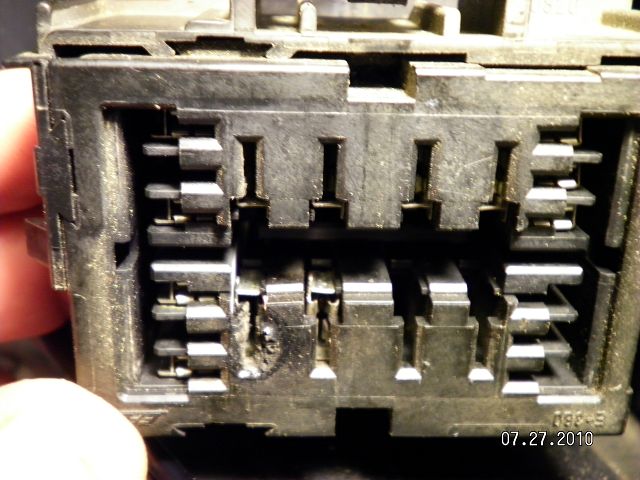

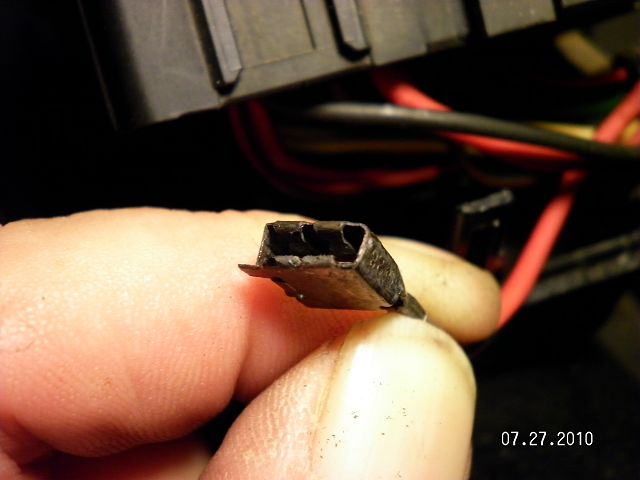

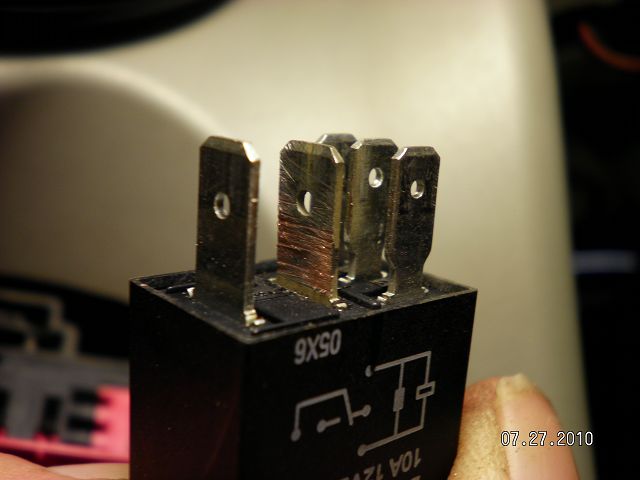

Ok, here is a little image with instructions on how I repaired my relay box. Sorry if it's posted in the wrong area, but here it goes anyway. Some are mechanically inclined and don't need this visual thing, but for those who do need visual help, here it is. First, remove the cover from the left side relay housing. Should look something like this on an XB12R 2004 and others.  Next, you should be able to see the melted connector in this photo, if not here is another one that shows it clearly  OK, now remove the red separator, you'll need a little sharp tool to do this, but it comes right up easily.    Next, un-clip the bottom side. There is a clip on the side, pry it out and the bottom side will be accessible. check out the photo.  ok, this will expose the bottom of the wiring harness, this is where the connector comes out.  From the top side where the relay plugs into the harness, there is a little clip holding the wire connector in place. Press on this with a sharp object and release the wire from the bottom. Take you time here, it's not that hard. pull on the wire while your doing this, when the correct pressure is applied to the clip, the wire will come right out.   Look at the wire end, corroded and not making contact with the relay. Now it's time to clean the connector. Use a small file, and a small wire brush, when done it should look golden like brass, or copper. Here is what mine looked like before and after. Before  After  After the connector is cleaned, don't forget to clean the relay connector... Essential to make sure all contacts are clean.   I took a little file and cleaned the relay where the contact was bad. Once all contacts are clean put it all back together. Good contacts make for a good connection, and less heat will develop. Less heat and the longer the connection will last before it has to be cleaned again. Also, the relay will last longer. I hope this helps someone. While I was making this, some of the photos did not post correctly. If not, I'll try to fix it ASAP. End result, working like a charm. | ||

Rays |

Thanks for sharing - one suggestion on the relay, you could give that clean copper surface a thin coating of solder pretty easily. | ||

Obiewan |

How true, that would clean up nice. Good Idea. | ||

Greg_e |

You should probably fill that hole with dielectric grease to keep the air and water out, that may prevent another poor connection. Those terminals are probably plated with Nickel, and now there isn't any plating to keep the corrosion away, same for the copper on the relay. I wouldn't solder the relay, probably make things worse, replace it or try the dielectric grease, you should be able to get the grease in any autoparts store, and half of the big box stores in the auto department, normally around the headlights since a lot of vehicles "require" this grease in the connectors. | ||

Obiewan |

Thanks for that tip Greg, I'll do that this afternoon. I used to use that on the plugs, of my MX bikes, it was called Dow Corning compound. Works great for sure. Thanks again. Ody | ||

Rays |

Greg, I guess we'll have to agree to disagree on the solder making the bare copper worse. It would also assist fill in where material has been removed from the relay tab as that could reduce the contact force a little as well It would depend on how well that was done of course but I would think that a conductor that didn't corrode readily would be at least as good as an insulator. All pretty much a storm in a teacup when a fresh relay runs less than $10 I suppose. | ||

Obiewan |

Solder also melts at 360 to 370 F. A fresh relay is 14 bucks at the "Advance" with a 1 year warranty. I've been through 5 of them. And in the most precarious places also. I carry a spare now. The fix should prove to reduce the amount of relays I use......... hopefully.  | ||

Rays |

This might save you a few dollars: http://www.jpcycles.com/product/380-777 Good luck with the repair. | ||

Speedfreaks101 |

The reason the connectors fail is from repetitive heat cycles. Unless the "female spade" is replaced it will fail again, but more quickly. The issue is that with each heat cycle the terminal looses tensile strength (you can not regain the lost tensile strength). As it looses its strength the connection is degraded. This creates resistance & increases the load. Resistance in electricity equals heat so as the load is increased so is the heat , so it becomes a viscous cycle. Long story short: Replace the terminal, solder it in place and makes sure that you scab back in the wire far enough that it has not been affected by heat. The reason for the solder is that it will prevent an area for the circuit to degrade and lessen the issue with heat/resistance. | ||

Obiewan |

Agreed, I didn't have a new spade like the one that's in there to replace it with. It has a little tab on the side that holds in in. So I just cleaner her up for now. I'll try to find one and replace it then. Dankie! | ||

Vlightningx1v |

If anyone finds please post here! I found this the starter relay gets "loose". I would like to know if there is a good upgrade for this, what is compatible? I what to stop that viscous cycle. I haven't had to replace the relay yet, cleaned and really looking into it. I bought the bike and it came with a spare and by now I know this had been histoic. I can't blame the guy for this because it is not his fault. I was looking at the block and the terminals are loose and it does feel like a good amount of heat runs through it. QUESTION: Is this a common problem for some models and years or is it mainly the connectors? | ||

Vlightningx1v |

Obiewan, thanks for your post. (and the pictures are great) I did exactly that to two terminals and now it starts strong. I am trying to figure out why it gets that hot. Mine did have some heat but didn't melt. Does anyone know if the wire rating for the 05 xb12 starter relay is different that the one for the 1125cr. I'll post on this if there any changes on my relay issue. | ||

Obiewan |

Welcome Vlight, glad it was able to help. Poor connection is most likely the culprit for the added heat. I ride with my brights on most of the time so people can see me and I'm tired of people telling me I have a light out. LOL. So that adds to the added heat I'm sure. More current flowing through it most of the time when the high beams are on. The answer is, keep um clean I guess. I haven't heard of a recall or a mod to correct the problem as of yet. I have a couple of ideas, but they are kind of extreme. Would require a complete revamp of the entire relay/harness area. I'm choosing to keep and eye on it, and keeping them clean for now.... much easier. LOL.... | ||

Vlightningx1v |

I got my service and parts manuals today in the mail! It's like new porn! I found what I worked on was the key switch relay. That helped with the first problem. It makes sense now because of the lights switching on/off at time of issue. I was thinking I need a new battery or that my starter was giving me trouble but think I will do the same with the other relays first to see if it improves anymore. Why do I keep giving myself more projects, I guess it's because I have a love for these things! | ||

Obiewan |

I do the same thing. I keep making up things to work on, LOL.... Just last night I Converted my regular blinker bulbs to LED's .. worked out great. | ||

Gage_s |

Will this help me? My 03 xb9r is not getting power to the fuel pump? Blown relay? |