| Author | Message | ||

M1combat |

Are all O2 sensors the same? Do they deliver the same voltage at stoichiometric AF mix? If not, couldn't a person buy one that reports the necessary value at stoichiometric (14.7/1??) to make the Buell ECM think that it's running where it wants to (12.8/1??). Hmmm, Maybe I have those two numbers mixed... | ||

Easyflier |

The PCIII with o2 sensor does that below 3500 RPM (The area that can't be mapped). Not sure if it has any affect above that since you can map around it to achieve the stoichiometric ratio that you want. and yes, I think you have that reversed. | ||

M1combat |

Well, I was thinking for a system that doesn't have a PCIII or race ECM... For us Po-Folk. What about the 02 sensor though. Could it be replaced with a unit that would report the voltage the ECM is looking for at stoich. instead of lean? | ||

M1combat |

Didn't get a chance to check tonight... I had to swap an engine mount on my truck. I'll try to get to it tomorrow. | ||

Easyflier |

It seems possible, and was discussed last year but there was no simple solution. | ||

M1combat |

I seem to remember discussion of wiring a potentiometer but nothing of actually switching out the O2 sensor itself... I could be wrong and I suspect I'll find a million hits if I do a search for O2 sensor... | ||

Easyflier |

Switching it out for the heated part supposedly makes it more accurate, or at least that's what Dynojet claims. I'm not sure how to wire it one up without the PCIII but I think I remember seeing something about it in the knowledge vault, as well as a part number for the local auto supply store. If so there might be something to be gained from the more accurate readings sent to the ECM, not sure though. Maybe I need to take a look myself just in case I pull the PC from my bike so I can leave the O2 sensor where it's at. PITA to remove it to replace the original one. | ||

Stot |

Hey M1, All O2 sensors that would work with our ECM put out the same voltage for the same A/F ratio, anything that would put out a different voltage will put out a wildly different voltage, like volts different not millivolts. Is our O2 sensor a bullet connector? If so you can just put a POT in a section of wire with a bullit one end and a bullet the other and put it in line, If you find it dont work take it out again no harm done. Cya Stot | ||

Hootowl |

Not absolutely sure about the EFI on Buells, but in general, O2's work like this: One wire O2 sensors do NOT tell the ECM when it is reading a perfect A/F mixture. They can only tell it whether it is rich or lean. Three wire O2's are the same as 1 wire, except that they are heated. 4 wire, or "broadband" O2's can tell the ECM whether it is lean or rich and by how much. If Buells use the same method (I'm pretty sure they do) having a pot in place of the O2 sensor will not work. Whatever signal you give it, the computer will try to compensate for any lean or rich condition due to climbing a hill, changes in altitude etc, and since it is no longer receiving anything from an actual O2 sensor, it will continue to lean out/richen up the mixture to the limits of it's range. You bike will run like crap. Does the PC accept a 4 wire input? I used to have one, but I don't remember, as I didn't use the "hi performance" O2 sensor. | ||

Stot |

You miss the point Hoot, the pot goes in line with the O2 sensor and moves the output doesnt give a defined output. The output is still governed by the O2 sensor. Put a resistor in there to make a fine sensor say im lean and the ECM compensates to richen the mixture, the O2 sensor will adjust to the new mixture and report rich mixture thru the resistor, the resistor adjusts that to say to the ECM hey im fine. Now whatever altitude and temp etc that may affect the O2 sensor will still be taken into account but to keep the bike at your new rich mixture. Cya Stot | ||

Hootowl |

Ah. Thot someone said to replace it with the pot. My bad. | ||

Stot |

for those of you wondering, well if this works why doesnt someone already make it?? http://cgi6.ebay.com/ebaymotors/ws/eBayISAPI.dll?ViewSellersOtherItems&userid=vi rtual_speed&include=0&since=-1&sort=3&rows=50 Tis is exactly what were talking about doing bue he does it to the air sensor. Cya Stot edited by stot on April 02, 2004 | ||

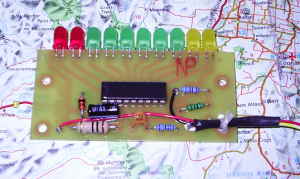

Opto |

I built this circuit from a kit, to try to get an idea when the ecm is in open loop or closed loop mode. Supposedly the LED's will flicker up and down in closed loop as the ecm constantly responds to the O2 sensor, and the LED's stay steady in open loop. The LED's are simply a voltage indicator of the O2 sensor output.  Power and ground wires off the headlight connector via fuse in the white heatshrink.  I couldn't go for a test ride after the instal due to adult beverages but the indications are looking good, it appears the XB12 stock ecm goes into closed loop after a couple of minutes at idle, will test ride next wkd.  The LED's were flickering all over the place with the usual unsteady idle (when cold). | ||

Unibear12r |

It would be great to hear more on this when you find out  | ||

Opto |

Went for a ride today. Looks like the ecm is in closed loop all the time until the throttle is opened more than about 1/4 (at high rpm it seems I have to open the throttle even more to enter open loop). While holding a steady 90mph, it is still in closed loop. In closed loop the O2 voltage oscillates continuously between <0.06V and <0.71V. In open loop the output is steady either between 0.62V and 0.71V, or (more often) its between 0.71 and 0.80V. It takes about half a second or less for the LEDS to become steady after opening the throttle. When the throttle is rolled off it goes to <0.06V until you get to fairly low rpm's. When I turn on the ignition with cold engine there is a steady voltage between 0.34V and 0.43V at the O2 sensor, after about a minute this increases to a steady voltage between 0.43V and 0.52V, about 30 seconds after that the ecm goes into closed loop, and the idle is noticeably less steady. This is from a cold start, ambient temp about 20 degrees Centigrade (68 F). I'm running a stock ecm, Drummer exhaust and K&N filter on XB12 with no snorkel. The voltage values given "between xV and xV" is because each LED represents a certain voltage range. | ||

Spike |

Opto, Nice work!  Where are you picking up the O2 signal? Any chance we can translate the voltage into an air/fuel ratio? Mike L. '04 XB12R | ||

Opto |

I'm picking up the signal near the ecm, the circuit has a 10 Meg input impedance so it doesn't affect the voltage through loading. Someone on this board mentioned 0.46V or 0.48V as stoichiometric for the Buell XB sensor, meaning 14.7/1 I believe. We could do with some info on this. The XB12 O2 sensor part no. is S0130.02A8, if anyone knows the manufacturer or the manufacturer's part number we could look up the specs to get some approx air/fuel ratios. I am also very keen to find out the manufacturer or manufacturer's part no. of the injectors Buell P/N P0026.1AA so I can find out how many lbs/hr or cc/min or however it's rated. |