| Author | Message | ||

Opto |

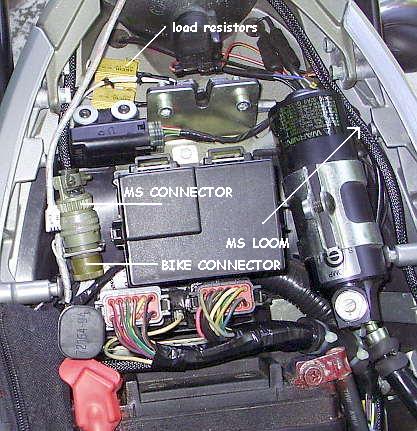

I finally got it all in a few days ago, will post some pics and brief description for any interested riders. I started this project back in March after I discovered I owned one of the few XB12's that wouldn't run well with a race ecm. I had a Drummer, K&N and no snorkel, and pinging issues due to the poor fuel we get (in Oz) once we leave the highway which is where I ride most. Also I was a bit disappointed with the driveability in city traffic after owning a carby Sportster for 6 years.  This is the pcb, it's a DIY board, check www.msefi.com for more info. Hanging above it in the plastic bag is a transistor and 2 resistors acting as a muffler servo emulator to keep the CE (check engine) light off. The black MAP sensor is not being used at this stage.  This is a shot during the install where I was splicing wires into the ecm loom to connect to the MS (Megasquirt). The MS runs piggyback and shares O2, tacho, power, IAT (inlet air temp), CHT (cyl head temp), and TPS. The new wires were soldered onto the existing wires and sleeved with heatshrink, I had to pull the pins out of the connector to fit the heatshrink.  The loom from the MS runs back under the seat on the left side right to the tail then back up the right side to mate with the loom I fitted to the ecm harness. The MS board and loom can be easily removed from the bike for repairs/mods. The 2 load resistors are used to keep the CE light off, the ecm injector outputs are switched through to these when the MS is switched in to take control of the injectors. The switch is under the seat on the right side and can be switched while riding. It is there in case MS fails and to make tuning easier and A/B comparisons.   This shows where the MS loom connects to the wires spliced into the ecm loom, the very small white connector is the computer access for tuning etc, ironically located very close to the ecm digital technician connector which I suspect is quite capable of reprogramming fuel and ignition of the stock ecm...won't go there... I've only done one tuning run and I use marks on the throttle corresponding to the TPS bins on the fuel map, the tacho and the LED display of O2 voltage to the right and above the tacho.   I had to remember where the bike was running richest, pull over, get the laptop out of my backpack and lean out the area I was working on, put the laptop back in the pack, sit on the excess lead connecting the computer to the bike, and go again. So far the bike is still running rich but I will take my time tuning it, there is no hurry. Initial impressions are the bike is running real smooth esp at low revs where it didn't before, no hiccups, coughs, stuttering. The idle is at least as good as the stock idle which dispels my fears about the sequential vs batch injection debate. The MS is firing each injector 360 degrees apart but I have no idea at what crank position the injectors open, except that there will be 45 degrees difference between the 2 cylinders. Overall it looks very promising at this stage and the initial tuning is not as difficult as I thought it would be. Once it gets close MS can datalog through the laptop to get it more refined. I was also worried about using TPS instead of the MAP sensor as this is not recommended by the MS people unless absolutely necessary, and there are no base fuel maps for TPS that I know of for a street machine, but the Buell was set up with TPS and everything is going fine at this stage. | ||

Barkandbite  |

Holy Sheit, Opto! My head hurts. All that work (and homework!) Impressive. Here I was thinking the Techlusion was neat. Chris | ||

Ingemar  |

Cool man! That looks neat. The led's above the tach, is that your o2 read-out thingy you posted about a while back? | ||

Glitch  |

WOW! Opto, I gotta hand it to ya. You da man! | ||

M1combat  |

Thank you Opto. I've been looking into this for a while and your input will be VERY appreciated. What are you doing for spark? You say the MS is running "piggy back"... Does that mean that the Buell ECM is handling spark and rev limit? | ||

Mookie  |

hmmmm. interesting, so can you give it to me in laymans terms how this works? does it replace the ecm? will i get a bonus by using this in conjunction on a xb9 with the race ecm? | ||

Dasbuell  |

My question... With the switch mounted under the seat near the shock and the heat blown off the rear cylinder onto that switch... are there concerns with what heat may do to the insulation of the wires? I have a pigtail for a battery tender... and I have to "hide" it from the heat where it is not directly being blown hot air from the rear head/fan. Before I "hid" it from the heat... in the summer it would get so hot I was concerned the insulation might melt off. It got VERY hot where a fingernail press could cut through it to expose the wire. Or at least seemed so... had I tried to do that. On a hot Ozzie day... and the hot air (or is that aire) off the rear head/fan... I would think that would/could be a worry!  | ||

Craigster |

Opto, Did you get my reply? | ||

U4euh |

Okay Opto you made me go look at your Bio. Man the thought of it all scares me. Props to you!!  Keep us posted as to how you smooth the bugs out. | ||

Trenchtractor  |

Dasbuell, Opto builds aircraft grade wiring harnesses, you can get some pretty high quality cable, like the teflon coated stuff I use at work that you can barely cut, let alone melt... Besides, that white wire he's used looks to me like aircraft grade materials...  Mookie, the MS is a DIY stand alone EFI. It can't control ignition yet and I don't think it does any fault indications yet either... You would more than likely plan to replace your ECM with it since it's fully programmable, but it's not a task for the faint hearted. M1, it's piggy backed for ignitin control ATM. I can only guess that he'll eventually run an aftermarket stand alone Ignition once he's happy with the initial testing of the MS... Opto, awesome job, it's great to see someone can actually loom properly. I love how you've incorperated extra cable in your looms... Sorry if I stole any of your thunder here... I would've used heat shrink tape rather than remove the pins, though, but I'm lazy...  At the moment, the set-up looks to me to be doing a similar job (in essence, not literally) to the TFi, but knowing the capabilities of the MS as a stand alone EFI and given that an aftermarket ignition could easilybe used, it's got awesome potential... I realy can't wait to see the outcome once you get the ignition, or the new MS that can do spark as well as fuel. Brad | ||

Opto |

Thanks for answering the questions Trench, appreciated. There is another BWBer already running MS on a tuber and we have started sharing info. M1 the beauty with MS is there are no secrets so when/if you have questions just ask. Just to clarify, the ecm still does everything it used to do, except when I switch over the MS exclusively controls fuel injection only. Dasbuell, thanks, the wires will be OK but I'll keep an eye on the temp of the switch. | ||

Trenchtractor  |

No worries.. I type fast... One of the side effects of running a desk job these days... Only downside is that before I know it I've written war and peice. Or said something to get Blake started...  Oops, I've done it again... lol Oops, I've done it again... lol | ||

Dasbuell  |

Not fair... All you aircraft techs get all the good stuff!!! One of the most amazing things to me beyond the overall done by Opto on his project... is that he got it all to fit under the seat of a XBxS model. Not much room left after the factory put all that stuff under the seat. I think the factory only designed space for the needed "stuff"... then only factored in additional space to make room for two pieces of paper so registration documents would fit under the seat. BUT... only if it was thin paper! Getting it all to fit was an accomplishment!!! Good job Opto!!! | ||

M1combat  |

You mentioned that you are not using the MAP sensor... I assume the O2 sensor negates the need for the MAP? How well do you think it will deal with elevation change? | ||

Craigster |

You need a MAP sensor to run speed density or just TPS and RPM to run Alpha-N. O2 is only if you want to enable closed loop correction. MS will run with std narrow band (you choose switching voltage) or NTK L1H1 sensor when operated by the DIY-WBO2 board (part of the original DIY EFI project - EFI 332) | ||

M1combat  |

Closed loop correction seems like a pretty important thing to me unless you are on a small racetrack... If I understand your answer correctly though... The O2 is indeed the replacement for the MAP. If the O2 is outside the spec you define it will decide to add (or remove I suppose) a couple ms to the firing length. This works just like the current ECM. Does it have something akin to the "AFV" value so that it remembers where it needs to adjust the curve to when you start the bike or would it have to re-learn each time you start the bike at a different elevation than where it was tuned? I looked into the MS and decided that I would need to tap a map sensor... Maybe I was wrong? (Message edited by m1combat on December 29, 2004) | ||

Craigster |

In speed density the processor looks at the manifold pressure and rpm and cross references the two values in a look-up table. Low pressure is equivelent to a closed throttle, high pressure equals an open throttle. The only thing the TPS is used for is accel enrichment (this can be replaced by MAP delta over time for those with no TPS) If you plan to drive the machine for 100,000 miles and would like the MS to perform minor tuning corrections the O2 sensor can and will adjust fueling. You set the limits. For instance if you believe that the O2 should never have to adjust fueling by more than +/- 10%, you can set that as a cap, and no extra correction will result out side that window. The amount of adjustment (or adjustment limit is entirely up to you). O2 sensors usually switch (they toggle back and forth from 0-1 volt) around 0.50 -0.59 volts. You can select the actual switching point in volts should you find your O2 sensor sees stoichiometeric -14.7:1- at some other voltage. with MS you can also set the rpm and engine temp at wich O2 correction is enabled. O2 sensors respond slowly to exhaust gas changes so it is expected that the engine be at a stable throttle position and rpm. Even wideband sensors take at least several hundered milliseconds to respond, hence they're not good for real time fueling adjustments (like MAP or TP are). If you have your fueling tables correct you can run speed density or alpha-n without O2 correction. I my self do not have O2 correction enabled untill 9000 rpm.....hence no correction at all regardless of input voltage.Most Metric bikes make do with out O2. In fact I have a hayabusa in the shed with amore high strung engine than the Buell and there is nary an O2 to be found on it. Fortunately for me I have access to a dyno with variable load, Air/fuel monitor and On screen torque reading (even more important to me than the air/fuel actually!). If you dont want to tap your manifold for a map sensor, just run in Alpha-N. The Map sensor will only be used for barometric correction should you decide to enable that feature. Intake air temp will still trim the values based on the General Motors algorithm. The only issue with running pure alpha-n is the current code will enrich or enlean based on map. Great for speed density (i.e. climb a mountain and as the pressure drops the fueling is cut accordingly) but with alpha-n this feature is unable to compensate since it is not operational during alpha-n. The Baro correction acts oposite of this, taking a reading at start-up and compensating for current weather conditions prior to engine vacuum influenced manifold pressure. Also a GM code hack. Fire up on the mountain and the baro correction add to pw slighly to compensate for the reduced pressure on the exhaust system. The lower ambient pressure also results in a lower pressure at the map sensor during operation so the enleanment for altitude takes place during real time fueling. I hope I explained that clearly. I intend to run 'blended alpha-n' soon (switching from alpha-n to Speed density at 3000 rpm) which will allow for better fueling during mountain rides, but I won't be able to test it out on a Mt. Washington until the spring! | ||

Trenchtractor  |

I think the point here is that Opto isn't using the MAP sensor YET... 'The black MAP sensor is not being used at this stage.' | ||

Opto |

Update: watching all the TFI progress keenly. Fitted a MAP sensor line, tried speed-density instead of TPS. Similar results but having problems getting good results overall, decided that tuning a fuel map is no walk in the park (I'm a newbie at this) so it's back to the drawing board to work out exactly how this new-fangled EFI works.  So I'm re-educating myself and will go back to TPS (alpha-n). The MS EFI works really well, just takes a lot to learn how to drive it  I'm making progress which is much better than going backwards. I'm making progress which is much better than going backwards. | ||

Steveshakeshaft |

Opto, great stuff. Watching from the sidelines with interest. Steve, ('97 M2 with Mikuni HSR42etc..) steve_s@ukbeg.com www.ukbeg.com | ||

Opto |

Update: I got a handle on the inner workings of MS. I refitted it all back to the bike and got hold of a Fluke Scopemeter to measure the stock ecm's injector pulsewidths to make up a basic fuel map. This gave good results and made me wonder why the bike ran as well as it did in the early stages when I was more or less guessing. One of the main probs I have is not being able to adjust the fuel while riding, I'm picking up a 2nd-hand Palm V this weekend that I hope I can mount up to the handlebars to enable tuning on the fly. Putting it back in and checking snesors/voltages/tacho output:  The scopemeter mounted to the instrument panel/handlbars to take readings from the injectors when being run from the stock ecm:  Carrying a laptop on a bike is a bit cumbersome and the Palm will be able to datalog as well. Other issues I'm looking at is the tacho output does not have much drive current or voltage and is giving MS a less than decent signal (observed on the scope). I may have to switch to coil triggering, I think I've worked out how to do it. Also I'm having some minor probs setting up the cyl head temp sensor values to read properly. I'm really looking forward to getting the Palm, so far every time I get a good map and try to improve it by trial and error I make it worse, so tuning on the run should solve some mysteries for me. To date I've been really happy with the reliability of the MS hardware and software, but the learning curve to understand it and drive it has been demanding. I feel I'm at the point where it all gets really really good or really bad.  If the Palm delivers the goods and there are smiles all round I will probably fit a wideband O2 sensor to finish the job properly. I'm getting the feeling that MS is never quite "finished" though, I think it will be an ongoing project of refinement for a long time. If the Palm delivers the goods and there are smiles all round I will probably fit a wideband O2 sensor to finish the job properly. I'm getting the feeling that MS is never quite "finished" though, I think it will be an ongoing project of refinement for a long time. | ||

Opto |

The Palm with the new software and the wideband O2 has made tuning not only possible but almost easy. The bike is running really well. I had a few time setbacks sorting out the tacho signal, the temp sensors and the choice of code to run in the microprocessor. The bike starts well, idles well, at low rpm/low load conditions the bike is noticeably smoother. I can now ride off on the bike with a cold motor with no hiccups or hesitations. All in all a very satisfactory outcome. Hope to check the WOT performance on a dyno soon, I can still switch between stock ecm and Megasquirt so a good A/B comparison can be made. I'm not expecting any significant gains but it would be nice. I feel the Buell technicians sacrificed some smoother running for emmissions, so my fuel consumption will probably increase. However MS can also run closed loop so I don't think I'll lose much at all. I'm 95% there, a bit more fine tuning is required. To say the bike runs really well is almost an understatement. Approximate cost of this project is US$200 for MS and parts, US$40 for a used Palm, and US$200 for an Innovate LC-1 wideband (I bought an Oz TechEdge 2CO). All the support and software is free, including source codes for the microprocessor. The MS project is a people's project, no big business involved. It works well. More info at www.msefi.com I only got to do some serious tuning on this bike in the last month or so after a certain Canadian dude decided to develop a program for tuning the MS with a Palm, without that I don't think I would have ever made it work. Thanks Roger Enns. | ||

Opto |

Still adjusting this and that, bike's running great but still more can be achieved, there's some later code with different accel enrichment operation and a baro correction option that is begging to be tried. Found a good priced dyno facility nearby, will go there soon. My partner reckons I'll still be working on MegaSquirt when I'm 70! Sounds OK to me. The LED's to the right of the speedo are now connected to a wideband O2 sensor displaying 11.5 to 16:1 AFR, the stock narrowband feeds the stock ecm and MS for EGO correction (stoich). Here's a pic of the Palm displaying the fuel map in edit mode, I have a 12 x 12 table available but still only using 8 x 8.  | ||

Opto |

The tacho signal from the ecm to the MS was always a bit varying so I hooked up MS directly to the 2 ignition coils to see if an improvement could be made. There was no real improvement but it means that one could use an aftermarket ignition now that MS can be triggered from the coils. If someone ever decided to go that way (MS and aftermarket ignition) then the MS could be wired to supply 5V to all the sensors including TPS, MAT, CHT, VSS and BAS, and also drive the fuel pump through a relay. That leaves only the fan to be taken care of, MS can do a fan, but not a 2-speed fan. MS can also drive a tacho if the aftermarket igniton can't. The CE light would become redundant. I don't intend to go any further than just the MS, unless I have pinging issues that can't be resolved with a bit more fuel or whatever. Summer is on it's way... I put in a later software (MSnS-E 025v2) that has rpm-based acceleration enrichment and that's looking like a good improvement (it will save wasted fuel at higher rpm's). I also swapped the injector wires so that MS bank 1 fires the rear injector first instead of the front injector first, the bike is noticeably smoother. Apart from some dyno runs to check wide throttle openings I don't think I can go much further, it pulls hard and runs smooth. I can switch it over to the stock ecm while riding, so the A-B comparisons are real. At the end of the day, all I've really gained is a bit of knowledge about FI and wideband 02 sensors, a smoother ride on the 04XB12S at lower revs (under 3200rpm), better cold rideability, and more consistent performance/rideability. For someone who wants to modify or race an XB12 the MegaSquirt system would be hard to beat, especially considering the cost and secondly the support forum www.msefi.com. For those who have a relatively stock bike like mine the outcome would probably not justify the effort required, unless you have plans for major mods in the future or just want to learn about EFI. The MS will not be removed from this bike, it runs too well... | ||

Opto |

5 months have gone by, there has been a lot of development in the MS world, it's hard to keep up with the changes/improvements that seem to be happening at an exponential rate.. I've improved on the tuning of the bike and it really is a joy to ride. Unfortunately I left the stock ecm connected to its O2 sensor and because I've been running a bit more fuel the stock ecm has leaned itself out to the point where it will barely run the bike - darn. I'll bet it's running the lowest AFV possible. The tacho signal problem was solved by the software developers. The acceleration enrichment has been greatly improved. Started running 9x12 tables instead of the old 8x8 (12x12 is available). Switched to simultaneous injections each revolution instead of alternating injections each 2nd revolution today, feels good but too early to tell, the dyno might show something. I did get it dynoed a couple months ago and while it was nothing to write home about, it was quite respectable, am hoping the simultaneous squirts might do something like even up the mixture between the 2 cyls so there is no charge robbing (speculation and wishfull thinking). I don't really want to fit a wideband to the front cyl as well as the rear cyl to check the fueling, quicker to try the simultaneous squirts and put it on the dyno. I bought a Uly and the rideability is miserable compared to the MS'd Lightning, plus it doesn't sound as good or healthy with the same pipe. So it will probably get an MS too, but the MS crew have come out with ignition code to support oddfire engines so I'm looking into MS fuel only first and then add ignition second. I think this will keep me busy for a while. I have a vision of a Uly running without a Buell ecm and little plastic bags covering the ecm connectors to preserve them from the elements. The success of running fuel only makes me wonder what sacrifices if any were made on the ignition side of things in the interests of emissions, so now I'm curious. If I can run MS ignition I will finally crack the pinging on poor fuel problem, which was one of the original motivations for starting the MS project. I can set up 2 ignition tables and choose either with a switch, one for good fuel, one for poor fuel in the middle of summer. It is good to see that the stock ecm code finally got cracked, I hope it all turns out well. | ||

Formerslimjim |

Opto, Have you tried using the MAP sensor with the Hybrid alpha-N feature of MSnS-E? It is a modified algorithm that uses alpha-N at idle and transitions into speed-density as you go up the RPM range. Also, I am interested in the injector data that you datalogged with the Fluke scopemeter. Can you post or Pm the data? It would be much appreciated. Jim | ||

Opto |

No Jim haven't tried that yet as I'm really happy with straight Alpha-n, but may try it when I run out of other things to fine tune. I've been away from home and still am hence the slow reply. If you want some info on injector pulsewidths I can PM that to you when I get home, less than a week away, or even the fuel map, but that wouldn't tell actual pulsewidths without calculations, whatever you like, I don't have any secrets, and would like to see more people using MS. The more the merrier. | ||

Opto |

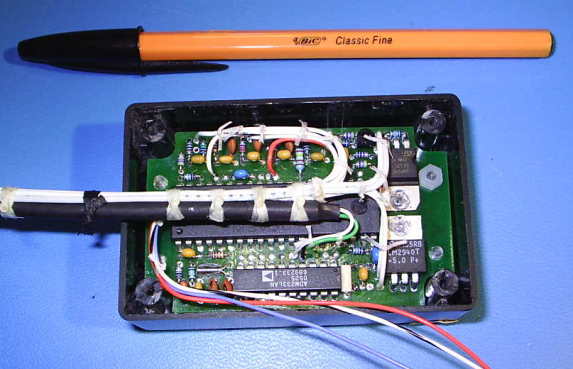

I finally got the MS in a box and under the seat of the Lightning!! Many thanks to Formerslimjim, who designed the miniature "Bare Bones" MS PCB specifically for Buells, but it could work on other bikes too. It has the minimum required components which are fitted as snugly as possible. It's tiny! This PCB really is a work of art. I never thought it possible. I was so glad to remove that huge 6" x 4" MS PCB from the hollow where the muffler actuator used to live.  This pic was taken before completion but is the only one I have with a pen in it to give you an idea of the size. The 3 wires hanging out are for the baro sensor for constant barometric correction, which fits inside the case after a little surgery. It cost AUD$120 to build. The box is mounted between the fuse box and the seat latch, and the wideband controller is on top of the battery. Haven't dynoed the bike since running the simultaneous injection events but have some expectations and the bike is running extremely smooth. Still waiting on upcoming MS developments before attempting ignition control. | ||

Steveshakeshaft |

That is a great Project to watch happening from the sidelines. Only yesterday I was reading the information about Micro-Squirt. It looks like Micro-Squirt is going to be a huge success. Thanks for sharing. Steve. | ||

Formerslimjim |

Yes I believe the Microsquirt is going to be a real success once B&G get it to market and get all the bugs worked out. The good part is the "Bare Bones MS" PCB that Opto is using can be upgraded with the MSII daughterboard so that it can also run the same code as the MSII / Microsquirt. With a few extra components it will function the same which makes it fully upgradeable. I am doing my best to plan ahead. |