| Author | Message | ||

Zoedogg1 |

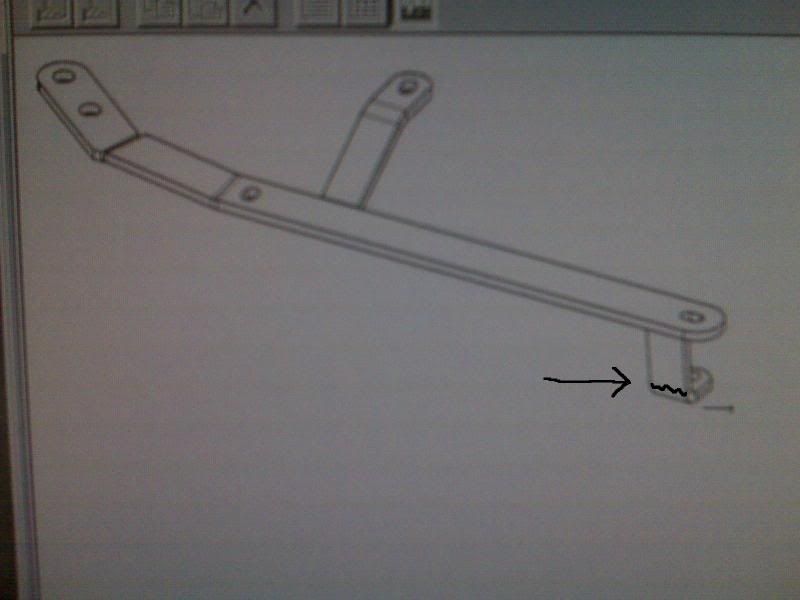

I have had a Jardine RT1 pipe since Feb. and my chin fairing bracket has broken twice in the same place. If anyone has had this experience with these problems let me know, and how you fixed it. I welded mine once and it broke again in the same place. This is the bracket that holds the chin fairing on, on the right side. Im guessing this is a high heat and stressed place on the bracket. I have been thinking about making something that is adjustable and forgiving under stress but doesnt break. This is a crappy pic of where my problem is.  | ||

Iamarchangel |

I would suggest that you fabricate a new tab that you would bend and weld to the main piece. Before you bend the tab put a "waist" in it where the bend is, just a little )(. Make sure that you radius all the edges. (When you bend steel it puts a lot of stress on the bend, you can see the fractures and they become a start point for the breaks you're getting.) The other choice would be to put a semi-circular notch on the down part of the new piece. Can't really guess on the dimensions of your piece but a bit smaller than the radius at the end of the main piece. Doesn't have to be much. Another option would be to put a hole in the middle of the down piece, the diameter about a 1/4 of the width. These are all stress relief ideas, managing the weaknesses. It lets the steel move in a stronger place than where it was moving before. It's important to radius every edge that you've ground, and the bend. The weld isn't taking because, if it's a good weld, it's now stronger than the surrounding metal. If it's a bad weld, it's weaker. The stresses will focus on the difference. You can get around it by heat treating but that's an art. If you bevel both sides of the broken piece and weld through the joint to the opposite weld, that would be best. But we're only talking about, what?, 3/16th steel. After the weld, you could try to flame heat the whole piece around the weld to cherry red and let it slowly cool. The whole piece should be the same strength but probably too soft. It's an art. Best to bend a new piece and weld it to the main piece. | ||

Zoedogg1 |

Thanks for the input. Yeah, I was thinking about a new bend and actually bolting it on the main piece with a couple 1/4" bolts. I figured that would give it the ability to move if needed without breaking...I dont know, I will probably just re-weld it with a new bend like you mentioned. Thanks again |